Exploring the Advantages of 10hp Vfd Over Traditional Motor Solutions

Table of Contents

- Understanding the Basics: What is a 10hp VFD and How It Works

- Key Benefits of Using a 10hp VFD in Industrial Applications

- Comparing Efficiency: 10hp VFD vs. Traditional Motors

- Cost Savings: Long-Term Financial Benefits of 10hp VFD Systems

- Installation and Maintenance: Simplifying Your Motor Solutions with VFDs

- Real-World Case Studies: Success Stories of 10hp VFD Implementation

- Maximize Your Motor Performance with the General VFD 55kW 380V 3Phase Inverter: A Guide to Efficiency and Control

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing industrial world, having reliable and efficient motor solutions has honestly *never* been more important. Companies are really looking for ways to optimize everything — and that’s where new tech comes into play. One innovation that's been catching everyone's eye is the 10hp Vfd, or variable frequency drive. It’s a game-changer compared to the old-school motors we’re used to. Companies like Zhejiang Chuanken Electric Co., Ltd., a high-tech firm with 15 years of experience in industrial automation control, are leading the charge here. By using the 10hp Vfd, businesses can better control their motors, which means better performance, less energy wasted, and fewer maintenance headaches. In this post, I’ll highlight some of the top benefits of the 10hp Vfd and show how it’s really changing the way industries are approaching automation and making things more efficient.

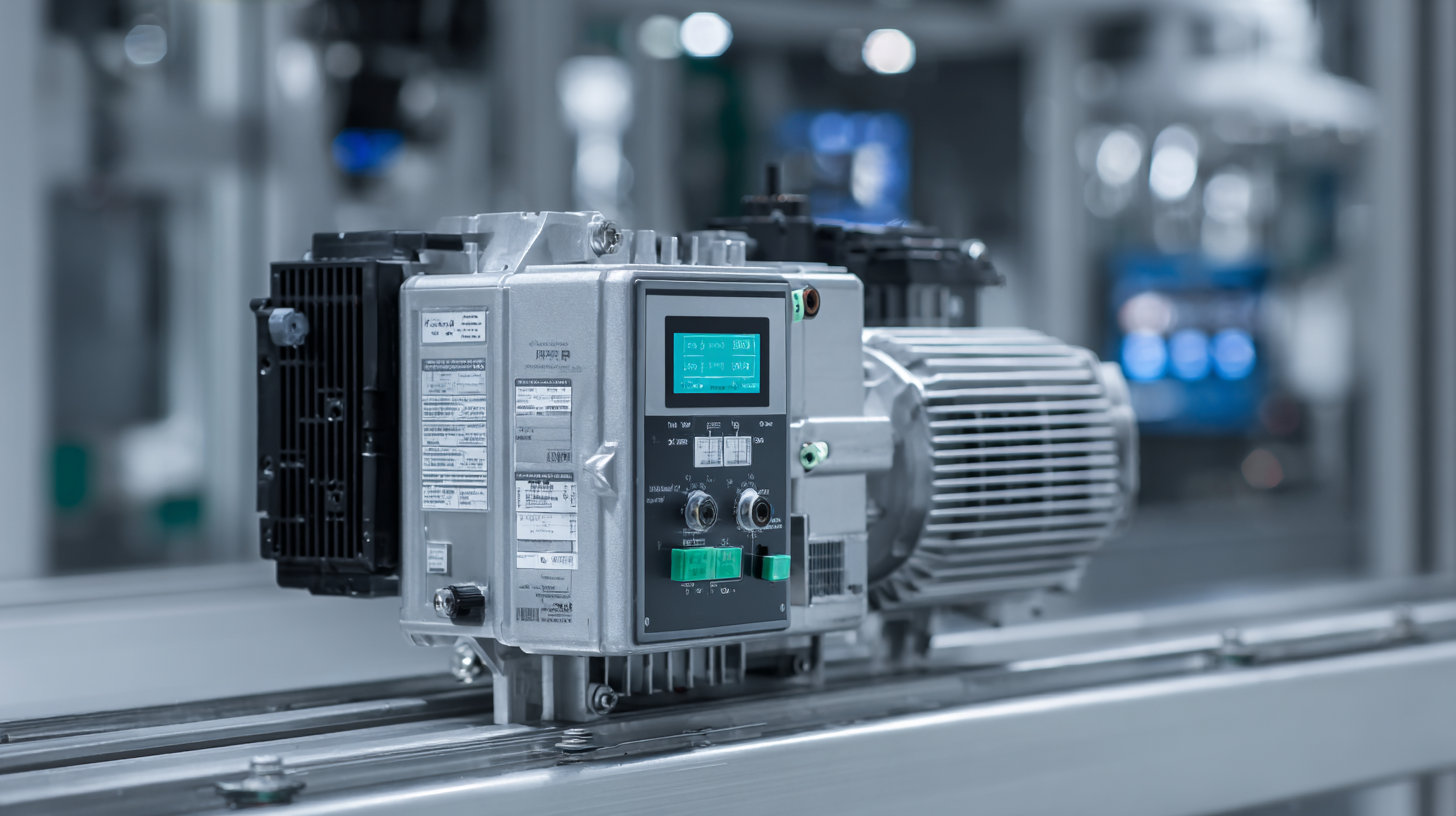

Understanding the Basics: What is a 10hp VFD and How It Works

A 10hp variable frequency drive (VFD) is really a game-changer when it comes to industrial automation. It offers way better control over motor speed and torque than your standard motors. At Zhejiang Chuanken Electric Co., Ltd., we totally get how important advanced motor control systems are these days. Basically, a VFD works by tweaking the frequency and voltage that go to the motor, giving you precise control over how fast it runs. According to a recent report from the International Energy Agency, using VFDs can boost system efficiency by up to 50%, which means big savings on energy bills for businesses—pretty impressive, right?

One of the biggest perks of a 10hp VFD is that it can actually help your equipment last longer. Since it reduces the wear and tear that comes with starting motors directly on line, it means less maintenance and less downtime. Plus, VFDs can really help streamline your processes by smoothly adjusting motor speeds to match different load requirements—so you’re not wasting energy or time. All in all, they’re a smart upgrade that can seriously bump up your productivity.

**Pro Tip**: When you’re picking out a VFD, make sure it's the right size for your setup—that way, you get the most out of your investment. Also, keeping an eye on how your VFD is performing can help catch potential problems early, saving you some headaches (and money) down the line. Adopting this tech isn’t just about efficiency; it’s also a step toward more sustainable and responsible business practices. Honestly, it’s pretty much essential in today’s industrial world.

Key Benefits of Using a 10hp VFD in Industrial Applications

Adding a 10hp Variable Frequency Drive (VFD) to industrial setups really brings a bunch of perks compared to the old-school motor solutions. For starters, it gives you a much finer grip on how fast the motor runs—so you get better efficiency all around. By tweaking the frequency and voltage going to the motor, this VFD helps keep everything running smoothly under different conditions, cutting down on energy bills and operational costs. It’s pretty impressive how much smoother things run with that level of control.

Plus, the VFD’s flexibility really shines when it comes to process control and the overall quality of the product. Industries like manufacturing or HVAC systems that need to change speeds on the fly find that a 10hp VFD makes their equipment respond faster and stay more stable. That not only improves performance but also puts less stress on the machinery—meaning fewer breakdowns and less downtime for repairs. And, because it has soft start features, there's less jolt of current when turning things on, which helps protect the motor and other connected parts. All in all, it’s a win for boosting productivity while also being gentler on the environment through smarter energy use.

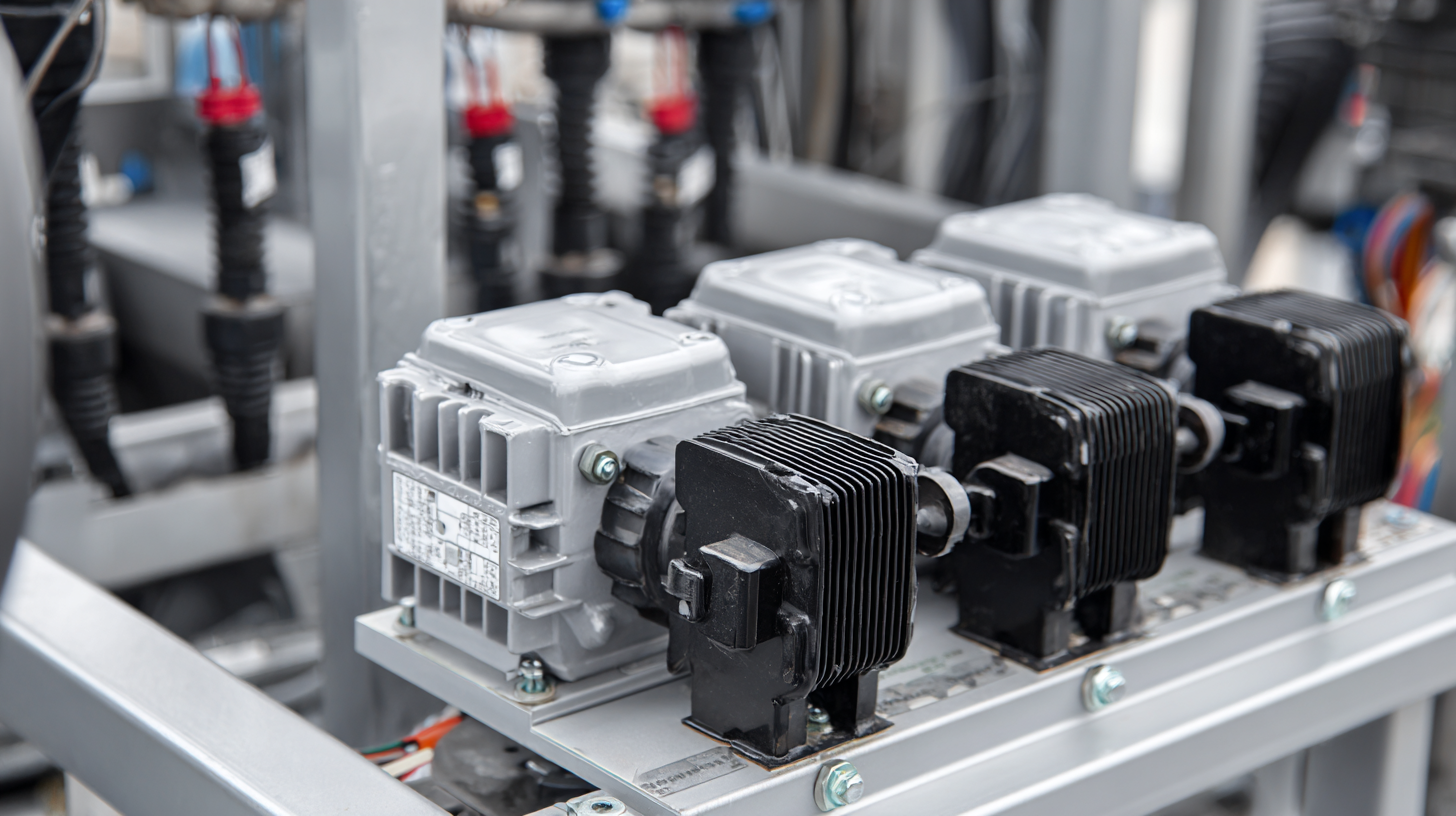

Comparing Efficiency: 10hp VFD vs. Traditional Motors

You know, the development of variable frequency drives, or VFDs for short, has really shaken up how we think about motor tech. They offer some pretty big perks compared to the old-school motors we used to rely on. Take a 10hp VFD, for instance — it’s noticeably more efficient. Unlike regular motors that run at a fixed speed and guzzle a lot of energy when starting up, a 10hp VFD gives you the flexibility to adjust speeds and torque as needed. That means not only does it trim down energy use, but it also puts less stress on the motor, which helps it last longer and keeps maintenance costs down. Win-win, right?

On top of that, with the world’s push towards being more energy-efficient, VFDs are more relevant than ever. The global market for automotive energy efficiency, for example, is expected to grow a ton in the next few years, and dropping a 10hp VFD into the mix can really help hit those efficiency targets. As industries move more toward automation and smart tech, the benefits—like saving money and boosting performance—make VFDs pretty much essential. In this fast-changing scene, companies that jump on board with smart solutions like the 10hp VFD will probably be the ones that stay ahead of the game.

Cost Savings: Long-Term Financial Benefits of 10hp VFD Systems

Switching over to 10hp Variable Frequency Drives (VFDs) is really a game-changer in the world of industrial motors, especially when it comes to saving money. If you're running a business, understanding how investing in these systems can save you a ton of cash in the long run is honestly pretty eye-opening. With a VFD, your energy use gets way more efficient because it adjusts the motor speed based on what’s actually needed for the process. Not only does this boost overall efficiency, but it also puts less strain on the equipment—meaning your machines last longer and don’t break down as often.

On top of that, VFDs really help cut down maintenance costs. Since they keep the motor running at a steady speed and reduce mechanical stress, you end up spending less on repairs and replacements. And that’s a big plus for keeping operations up and running smoothly. Basically, even though the upfront cost might seem a bit steep, investing in VFD tech can definitely pay off over time by improving performance and saving money.

**A quick tip:** When you’re thinking about switching to a 10hp VFD, take a moment to really check out what your specific needs are. Make sure the system you pick plays nice with your existing equipment so everything runs smoothly. Also, keep in mind that it’s not just about the sticker price—think about how much you’ll save on energy bills and maintenance costs over the years. Working with experienced suppliers like Zhejiang Chuanken Electric Co., Ltd., can make a big difference in making sure you get the most out of your VFD investment.

Exploring the Advantages of 10hp VFD Over Traditional Motor Solutions

This chart compares the financial implications and operational efficiency between a 10hp Variable Frequency Drive (VFD) system and traditional motor solutions, highlighting potential cost savings in various categories.

Installation and Maintenance: Simplifying Your Motor Solutions with VFDs

You know, the introduction of Variable Frequency Drives (or VFDs) really changed the game when it comes to installing and maintaining motors. They give you pretty precise control over how fast and how much torque your motor delivers, which not only helps save energy but also makes the whole operation a lot smoother and easier. I read somewhere that according to the U.S. Department of Energy, using VFDs can cut energy costs by about 20 to 50 percent — that's a big deal for lots of industries trying to keep expenses down.

When you're installing a VFD, don’t worry — they’re designed to fit right into existing systems without much fuss. That means less downtime and fewer major modifications. Plus, you can customize their programming for different applications, making startup and adjustments a breeze. And when it comes to keeping them in good shape, many VFDs have built-in diagnostic tools that can monitor how the motor is doing in real-time. This helps technicians spot potential issues early, before they turn into costly repairs, which means less downtime overall.

**Pro tip:** When you're setting up a VFD, think about the environment—things like temperature, humidity, and electromagnetic interference can really affect how well it works.

Another thing to keep in mind is training your team properly. The more they understand about the VFDs, the faster they’ll be able to troubleshoot problems and run routine checks to keep everything running smoothly.

**Quick tip:** Make sure to keep your firmware and software up to date. That way, you’ll get access to the latest features and improvements, helping your system perform at its best.

Real-World Case Studies: Success Stories of 10hp VFD Implementation

Switching over to 10hp Variable Frequency Drives (VFDs) has really been a game-changer for a lot of industries. They offer a bunch of benefits compared to the old-school motor setups. Actually, real-world stories show just how much more efficient operations can get with VFDs in place. Take a manufacturing plant, for instance — they managed to cut their energy bills by about 30% after making the switch. Not only did they save some serious cash, but their motor control got way better too.

But here’s the thing—getting everyone on board is super important for a smooth rollout. Involving staff through proper training and making them feel part of the transition really pays off. When employees understand what VFDs do and see the benefits firsthand, they’re much more likely to get behind the change. Sharing success stories and data that show performance improvements can also help create a positive vibe around the new tech.

**Here’s a quick rundown of tips to make the implementation a success:**

- **Offer solid training:** Make sure your team knows how VFDs work and why they’re beneficial — it helps them feel confident about the new tech.

- **Ask for feedback:** Create a space where employees feel comfortable sharing their thoughts and experiences. This can lead to continuous improvements.

- **Celebrate wins:** Don’t forget to acknowledge and reward teams who adapt well. It keeps morale high and reinforces the importance of everyone’s contribution during the process.

Maximize Your Motor Performance with the General VFD 55kW 380V 3Phase Inverter: A Guide to Efficiency and Control

Maximizing your motor performance is crucial for achieving operational excellence in any industrial setting. When it comes to enhancing efficiency and control in your motor systems, the General VFD 55kW 380V 3Phase Inverter stands out as an indispensable tool. This versatile inverter not only optimizes energy consumption but also ensures consistent performance across various applications. Whether in manufacturing, pumping, or HVAC systems, having the right inverter can lead to significant improvements in productivity and cost savings.

In this pursuit of efficiency, the SHCKELE SCK300 model emerges as a reliable choice, boasting an 18-month warranty that underlines its quality and durability. This general-purpose inverter is designed to adapt seamlessly to your motor needs, providing smooth speed control and reduced power usage. With its user-friendly interface and robust performance metrics, the SCK300 enables operators to fine-tune motor functions with precision, leading to enhanced operational control. Investing in such advanced technology not only streamlines processes but also aligns with sustainability goals by minimizing energy waste.

FAQS

: Investing in 10hp VFD systems leads to substantial reductions in operational costs, optimized energy consumption, minimized wear and tear on equipment, and lower maintenance costs.

VFDs optimize energy consumption by allowing motors to adjust their speed according to the specific demands of a process, enhancing efficiency.

VFDs lower maintenance costs by maintaining a consistent speed and reducing mechanical stresses, which helps avoid frequent repairs associated with traditional motor systems.

By enhancing efficiency and reducing downtime through improved maintenance practices, VFDs directly contribute to increased availability and productivity in operations.

Businesses should assess their operational needs, ensure compatibility with existing equipment, and consider not just purchase prices but the reduced energy and maintenance costs over the VFD's lifespan.

Yes, VFDs are designed to fit seamlessly into existing system frameworks, minimizing downtime and the need for extensive modifications.

VFDs often include diagnostic features for real-time monitoring, which helps technicians identify potential issues early, reducing downtime and repair costs.

Proper training enables staff to quickly troubleshoot issues and perform routine checks, ensuring optimal performance and longevity of the VFD systems.

Factors such as temperature, humidity, and electromagnetic interference should be considered during installation to ensure optimal performance.

Regularly updating the software and firmware of VFDs helps organizations access the latest features and performance improvements.

Conclusion

In today’s industrial world, using the latest tech is pretty much essential if you want to run things smoothly and efficiently. Take the 10hp VFD—also known as a Variable Frequency Drive—it’s a pretty smart gadget that helps control motor speed and torque, which means you’re saving energy and boosting overall performance at the same time. When you compare a 10hp VFD to old-school motor setups, it’s clear there are some pretty big perks: more efficiency, lower energy bills, and long-term cost savings.

Here’s the thing—Zhejiang Chuanken Electric Co., Ltd., with over 15 years under their belt in developing automation control stuff, really stresses how useful it is to include 10hp VFDs in motor systems. These things are not just easier to set up and maintain—they’ve also led to some pretty impressive results across different industries. So, if you’re thinking about investing in a 10hp VFD, you’re basically choosing a smarter, greener, and more cost-effective path for your business down the road.

Related Posts

-

Understanding the Common Issues Faced with Best Vfd 2.2kw in Global Procurement

-

Exploring the Versatility of the Best 160kw Soft Starter: Applications and Key Features

-

Discover the Top 10 Vfd Applications for Enhanced Performance and Efficiency

-

Step-by-Step Guide to Sourcing the Best China VFD for Your Business Needs

-

Future Innovations in Vfd Drive Power Boards for 2025 Tech Advancements

-

5 Essential Tips for Choosing the Best Bypass Soft Starter