Exploring the Advantages of 3 Phase Soft Starters: Why They're Essential for Modern Motors

Table of Contents

- Advantages of Soft Starters in Reducing Motor Starting Torque and Electrical Stress

- Impact of 3 Phase Soft Starters on Energy Efficiency in Industrial Applications

- Comparison of Soft Starters vs. Traditional Starters: Performance Metrics and Costs

- How 3 Phase Soft Starters Enhance Equipment Lifespan through Controlled Acceleration

- Case Studies: Real-World Savings Achieved with 3 Phase Soft Start Solutions

- Future Trends: Innovations in Soft Starter Technology for Advanced Motor Control

- FAQS

- Conclusion

- Related Posts

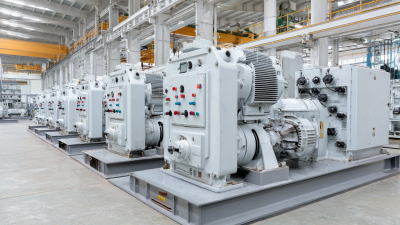

When it comes to industrial automation, using smarter motor control options really makes a difference. For example, the 3 Phase Soft Starter is a game-changer — it helps electric motors start up more smoothly, which means less strain on the machinery and a longer lifespan for your equipment. From what I’ve seen in recent reports, the market for soft starters is actually set to grow by about 5.3% annually from 2021 to 2026. That’s mainly because more industries — like manufacturing and HVAC — are on the lookout for energy-efficient solutions to control their motors better. Zhejiang Chuanken Electric Co., Ltd., with over 15 years of experience in creating innovative automation products, is really leading the charge in this space. We get how important these soft starters are for modern motor applications — they not only boost performance but also help keep industrial operations sustainable in the long run.

Advantages of Soft Starters in Reducing Motor Starting Torque and Electrical Stress

Soft starters are pretty important in today’s motor setups. They help cut down on the initial jolt of power and stress that motors normally face when they start up. This is especially a big deal in industrial environments where heavy machines are constantly turning on and off. By gently controlling the voltage and current fed into the motor, soft starters prevent those massive inrush currents—sometimes several times higher than what the motor's rated current actually is. This not only helps the motors last longer but also reduces the strain on mechanical parts, making everything run more smoothly and with fewer hiccups.

Looking at the latest in soft starter tech, we see some pretty cool improvements that boost how well motors perform and save energy. For example, newer soft starters come with smart controls that let the motor spool up gradually, so acceleration and deceleration happen smoothly instead of suddenly—that’s key for avoiding system hiccups or failures. Plus, with more companies pushing for energy-efficient solutions to meet stricter rules, the market for soft starters is really growing. These devices do more than just help individual motors; they also give a hand in keeping the entire power grid stable by easing electrical stress on supply networks. All in all, they’re a vital piece of modern industry equipment that keeps things running reliably and efficiently.

Impact of 3 Phase Soft Starters on Energy Efficiency in Industrial Applications

When it comes to industrial setups, 3-phase soft starters really make a big difference in how efficiently energy is used. You know, with industries pushing hard to cut down on costs and boost productivity, these devices are becoming more essential than ever.

Recent market insights show that the global market for automatic motor starters hit around $4.6 billion in 2024 and is expected to grow to about $7.3 billion by 2034. That’s a pretty clear sign that more companies are looking for smarter motor control options, and soft starters definitely fit the bill. They help cut down on those huge inrush currents and make motor acceleration smoother, which not only helps the motors last longer but also cuts down energy usage—a win-win for companies trying to go green and save some cash at the same time.

On top of that, the whole energy-efficient motor market is blowing up. You’ve got standards from IE1 all the way up to IE5, showing how much there's a real push for high-efficiency motors. When you combine 3-phase soft starters with variable frequency drives (VFDs), it’s like giving your motor the perfect control system—more responsive, more energy-friendly.

Here at Zhejiang Chuanken Electric Co., Ltd., we’re all about developing smart automation products because we get it—being efficient and sustainable isn’t just a trend, it’s the future of industry. So, yeah, investing in these kinds of solutions isn’t just a good idea; it’s kind of essential if you want your operations to keep up in today’s world.

Here at Zhejiang Chuanken Electric Co., Ltd., we’re all about developing smart automation products because we get it—being efficient and sustainable isn’t just a trend, it’s the future of industry. So, yeah, investing in these kinds of solutions isn’t just a good idea; it’s kind of essential if you want your operations to keep up in today’s world.

Comparison of Soft Starters vs. Traditional Starters: Performance Metrics and Costs

Lately, there's been quite a shift in the industrial world—from the old-school motor starters to the newer soft starters, especially the three-phase types. If you take a closer look, you'll see that soft starters really outshine traditional ones across a bunch of performance areas. For example, studies show that soft starters can cut down the initial surge current by anywhere from 50% to 70%. That means less stress on your electrical parts and a longer lifespan for your equipment. This is especially important when you're dealing with heavy machinery that gets started and stopped a lot; traditional starters tend to wear out pretty quickly in those situations, which can end up costing you more on maintenance in the long run.

On top of that, soft starters help make operations more efficient. A report from a well-known motor tech company mentions that by using soft starters, you can boost energy efficiency by around 30%. That’s a big deal if you're looking to cut down on your running costs. Traditional starters, on the other hand, can cause more wear and tear on your motors and electrical systems, leading to higher repair and replacement bills down the line.

**A few tips:** When you're choosing between soft starters and the old-fashioned ones, think about what your specific setup needs. If your machinery starts and stops quite a bit, soft starters are probably your best bet—they can help reduce wear and tear and keep your equipment running longer. Also, don’t forget to weigh the upfront costs against the long-term savings. Sure, soft starters might cost a bit more initially, but the efficiency gains and less maintenance can make them a smarter investment overall.

Exploring the Advantages of 3 Phase Soft Starters: Why They're Essential for Modern Motors - Comparison of Soft Starters vs. Traditional Starters: Performance Metrics and Costs

| Parameter | 3 Phase Soft Starter | Traditional Starter |

|---|---|---|

| Starting Current | Reduced (up to 50%) | High (6-8 times FLC) |

| Motor Protection | Yes (overload, phase loss) | Limited |

| Control Type | Programmable (variable starting profile) | Fixed (direct on/off) |

| Cost | Higher initial investment | Lower initial cost |

| Energy Efficiency | Higher (saves energy during startup) | Lower |

| Application Range | Widely applicable (pumps, fans, conveyors) | Limited (basic applications) |

| Installation Complexity | Moderate (requires configuration) | Simple (plug and play) |

How 3 Phase Soft Starters Enhance Equipment Lifespan through Controlled Acceleration

Three-phase soft starters are pretty essential when it comes to modern motor setups, especially since they really help extend your equipment's lifespan. Basically, by controlling how quickly the motor ramps up to full speed, these devices cut down on the mechanical stress during startup. That slow, steady increase in speed means there’s less chance of sudden jolts—those rough starts that can wear out parts and cause problems down the line. Because of that, you can count on your motors running more reliably and lasting longer, which makes investing in soft starters a smart move.

If you're thinking about using three-phase soft starters, there are a couple of things to keep in mind. First off, double-check that the soft starter you pick matches your motor’s specs and your specific application needs. Picking one with the right voltage and current ratings is key to making everything run smoothly. Also, don’t forget to tweak the adjustable settings—like acceleration times—to fit your startup process just right. And hey, doing regular maintenance checks can seriously boost how well everything performs and help your equipment last even longer. In the end, it’s all about keeping your system running smoothly and getting the most bang for your buck.

Benefits of Using 3 Phase Soft Starters in Modern Motors

Case Studies: Real-World Savings Achieved with 3 Phase Soft Start Solutions

You know, using 3-phase soft starters in modern motors has really shown some pretty impressive benefits, especially when you look at real-world situations. Lots of cases reveal that industries switching over to these soft start solutions are actually saving quite a bit on operating costs and maintenance stuff too. For example, I read a study from the International Electrotechnical Commission — and they mentioned that companies can cut down their energy use by up to 30% thanks to soft starters. That's mainly because these devices cut down the inrush current when the motor kicks in, which not only makes everything run smoother but also helps the equipment last longer.

On top of that, more and more industries are catching on to how valuable 3-phase soft starters can be for keeping systems reliable. I came across a survey by the Electric Power Research Institute — and it showed that companies experienced about a 25% drop in motor wear and tear. That kind of decrease means less downtime and fewer repair headaches. As we’re heading into a future filled with smart robotics and automation, I honestly think integrating these soft starters is going to become even more crucial. They’re not just about saving energy; they also support more sustainable industrial practices, which is a big plus. All in all, these solutions are really a solid step forward in modernizing the whole industry.

Future Trends: Innovations in Soft Starter Technology for Advanced Motor Control

The way soft starter technology is evolving is pretty exciting—it really plays a big role in improving how motors are controlled across different industries. As more folks are looking for energy-efficient solutions, today's soft starters are designed to cut down on those huge inrush currents, which helps protect the motors and actually makes them last longer. Market trends show that the soft starter market is really booming right now, mainly because everyone wants better efficiency and because new energy regulations are pushing industries to upgrade. That’s led to more devices now coming with cool features like built-in diagnostics and real-time monitoring, which keeps everything running smoothly and cuts down on unexpected downtime.

On that note, Zhejiang Chuanken Electric Co., Ltd. is really stepping up to lead the way in innovative industrial automation products. With over 15 years of experience under our belt, we're super focused on research and development, which keeps us ahead of the curve in this fast-changing soft starter scene. Our goal is to create solutions that not only match what the industry needs today but also get ahead of future challenges in motor control tech. Basically, we want our customers to feel confident that they can count on us for top-of-the-line, innovative products that help them run their operations more efficiently.”

FAQS

: Soft starters significantly outperform traditional starters by reducing inrush current by 50-70%, enhancing longevity and reducing stress on electrical components. They also improve energy efficiency by approximately 30%.

Soft starters lead to lower maintenance costs because they reduce wear and tear on motors and their electrical systems, resulting in fewer repairs and replacements compared to traditional starters.

Soft starters are especially beneficial in environments with frequent start-stop cycles, such as heavy machinery applications, where they reduce wear and extend equipment life.

While soft starters may have a higher upfront cost, their efficiency and reduced maintenance needs can lead to significant long-term savings, making them a more cost-effective choice over time.

The incorporation of soft starters can improve operational efficiency by minimizing inrush current during motor start-up, which saves energy and prolongs the lifespan of equipment.

Yes, case studies show that industries using 3 phase soft starters can reduce energy consumption by up to 30% and have reported a 25% decrease in motor wear, leading to lower downtime and repair costs.

Soft starters enhance system reliability by reducing motor wear and tear, which correlates with lower downtime and fewer repair costs, making them a valuable investment for organizations.

The growing demand is driven by the need for energy-efficient, reliable solutions that align with sustainable practices in industrial operations, especially as technology advances with automated systems.

When selecting between soft starters and traditional starters, consider specific application requirements, total cost of ownership, and whether the operational efficiency benefits of soft starters justify their higher initial cost.

Conclusion

So, I came across this article called "Exploring the Advantages of 3 Phase Soft Starters: Why They're Essential for Modern Motors," and honestly, it sheds a lot of light on why these devices are a game-changer in industrial setups. Basically, these soft starters do a great job of reducing the huge jolt and electrical strain when motors start up. Not only that, but they also help save energy — which, of course, means knocking down costs for businesses. The article compares soft starters to the older, more traditional ways of starting motors, and it really makes a case for how much better these newer devices are when it comes to performance and savings.

Plus, the gentle, controlled startup that soft starters provide actually helps extend the life of the equipment, so things keep running smoothly over time. There are even real-world examples showing how much money companies have saved by switching to these solutions. And, if you're into future tech, the article hints at some pretty exciting developments on the horizon for soft starter tech, promising even better motor control down the line. As someone who's into industrial automation, I think Zhejiang Chuanken Electric Co., Ltd. really gets it—they see how vital soft starters are for making manufacturing more efficient and competitive today.

Related Posts

-

Understanding the Benefits and Efficiency of Soft Starters in Industrial Applications

-

10 Best 50hz 60hz Soft Starters for Efficient Motor Control

-

Understanding Soft Starters for Motors: A Comprehensive Guide to Optimal Performance

-

The Definitive Guide to Selecting the Perfect 280kw Soft Starter for Your Global Sourcing Needs

-

Understanding Import and Export Certifications for the Best Vfd Control Board in Global Markets

-

Unlocking Efficiency with the Benefits of the Best Pressure Booster Vfd Technology