7 Best Insights on Vfd 5.5kw for Industrial Applications

Table of Contents

- Understanding VFDs: Definition and Functionality

- Key Features of 5.5kW VFDs for Industrial Use

- Advantages of Using VFDs in Industrial Applications

- Selection Criteria for Optimal 5.5kW VFDs

- Common Challenges and Solutions in VFD Implementation

- Future Trends in VFD Technology for Industrial Sectors

- Maximizing Motor Efficiency and Longevity: Insights from Industry Reports on RS485 Soft Starters for 220V to 690V Applications

- FAQS

- Conclusion

- Related Posts

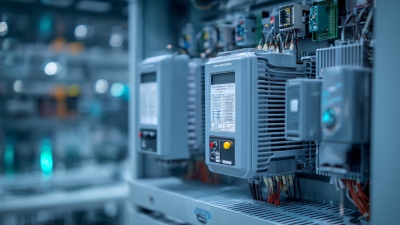

In the fast-moving world of industrial automation, Variable Frequency Drives (VFDs) have really become game-changers when it comes to boosting efficiency and cutting down energy costs. The 5.5kW VFD, for example, is pretty impressive because it gives you exact control over motor speed — which not only helps save energy but also extends the life of your equipment. I read somewhere that, according to MarketsandMarkets, the global VFD market is expected to hit around USD 25.69 billion by 2025. That says a lot about how much industries are focusing on smarter, more energy-efficient automation. Here at Zhejiang Chuanken Electric Co., Ltd., we’ve been in the game for more than 15 years, working on industrial automation control solutions. We really understand how important it is to stay ahead with the latest tech and innovation. So, in this article, I want to share the 7 most useful insights about the 5.5kW VFD for industrial use — things to look out for that affect how well it works and how reliable it is in today’s competitive market.

Understanding VFDs: Definition and Functionality

Variable Frequency Drives, or VFDs for short, are pretty much essential in many industrial setups. Basically, they control how fast and how much torque electric motors produce. How do they do that? By tweaking the frequency and voltage sent to the motor, giving you super precise control. This kind of flexibility is a game-changer across different industries because it helps things run more smoothly, cuts down on energy bills, and even helps extend the lifespan of equipment. If you're trying to optimize your factory or automation processes, understanding what VFDs are and how they work is definitely a smart move.

At Zhejiang Chuanken Electric Co., Ltd., we’ve been in the game for over 15 years, specializing in industrial automation control products. That experience really helps us deliver top-notch VFD solutions that match industry needs. We’re constantly investing in research and development to keep our products ahead of the curve. Our goal? To boost efficiency and help our clients cut costs. Thanks to cutting-edge tech and deep industry know-how, we’re proud to help businesses unlock the full potential of VFDs and take their operations to the next level.

7 Best Insights on Vfd 5.5kw for Industrial Applications - Understanding VFDs: Definition and Functionality

| Aspect | Details |

|---|---|

| Definition | Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of an electric motor by varying the frequency and voltage of the power supplied to the motor. |

| Functionality | VFDs convert the fixed frequency and voltage of an AC power supply to a variable frequency and voltage output, allowing precise control of motor speed and energy consumption. |

| Applications | Used in fans, pumps, compressors, conveyors, and other equipment requiring variable speed control in industrial settings. |

| Energy Savings | VFDs can lead to significant energy savings by reducing wasted energy in applications that do not require full speed at all times. |

| Control Methods | Common control methods include Volts/Hz control, Vector control, and Direct Torque Control. |

| Benefits | Improved process control, reduced mechanical stress, extended equipment life, and lower maintenance costs. |

| Key Specifications | Power ratings, input voltage range, output voltage range, control modes, and compatibility with different motor types. |

Key Features of 5.5kW VFDs for Industrial Use

Variable Frequency Drives, or VFDs for short, really play a huge role when it comes to fine-tuning how machines run in industrial settings—especially those around the 5.5kW mark. One of the coolest things about 5.5kW VFDs is how accurately they can control motor speed and torque. This means not only smoother operation but also those sweet energy savings you hear about. I read somewhere that, according to the International Energy Agency, using VFDs can cut down energy use by as much as 50% compared to the old fixed-speed setups. That’s a pretty big deal—it helps lower costs and even extends the life of your equipment, which is always a win in my book.

And here’s another thing: these VFDs are super adaptable, ready to handle all kinds of industrial environments. Most of them come with tough enclosures that can handle rough conditions—they often meet or beat IP55 protection standards. Plus, many models now come loaded with smart features like built-in safety functions that keep overheating and overcurrent issues in check. Interestingly, a recent report from Research and Markets mentions that the global VFD market is expected to grow at about 6.3% annually from 2021 to 2026. That says a lot about how much people are relying on these systems—whether it’s in manufacturing, HVAC, or water treatment industries. Basically, it’s a sign that VFDs are becoming more advanced and that energy efficiency is more important than ever in these fields.

Advantages of Using VFDs in Industrial Applications

Variable Frequency Drives, or VFDs for short, are really becoming a game-changer in industrial settings these days. You might not realize it, but one of the biggest perks is how much energy they can save. I remember reading that the U.S. Department of Energy says using VFDs can cut energy use by as much as 60% in some cases. That’s a pretty huge deal, especially if you’re dealing with manufacturing or heavy industry where costs tend to pile up quickly.

On top of that, VFDs help machines last longer and mean less time—or money—spent on maintenance. There was this study from the National Institute of Standards and Technology that showed motors can last 25% to 50% longer simply because they’re running at just the right speeds for the job. Not only does this mean less wear and tear, but it also saves tons of money on repairs and replacements over time. All in all, integrating VFDs just makes the whole industrial operation more efficient and sustainable.

Selection Criteria for Optimal 5.5kW VFDs

When you're choosing a Variable Frequency Drive (VFD) for a 5.5 kW industrial setup, there are a few key things you really want to keep in mind to make sure you get the best performance. First off, think about the control method. Most VFDs use either simple Volts/Hertz (V/f) control or more sophisticated vector control. If it’s a basic job, V/f is usually enough and easier on the wallet. But for more complex processes where you need better torque control and efficiency, vector control is the way to go. I’ve seen reports from the International Society of Automation (ISA) that say using more advanced control strategies can bump up energy efficiency by as much as 30%. Pretty impressive, right?

Another important point is the environmental rating of the VFD—especially if it’s going into tough conditions. If it’s a dusty environment but not too harsh, a VFD with an IP54 rating will probably do the trick. But if you’re dealing with moisture, dirt, or other challenging factors, you’ll want to go with at least IP65 to make sure it holds up. Picking the right rating really helps the VFD last longer and cuts down on maintenance costs down the line.

Pro tip: Always double-check the thermal specs of the VFD. It should have built-in protections to prevent overheating—that’s what keeps things running smoothly and safely.

And don’t forget about system compatibility. Take a look at what communication protocols the VFD supports—many modern models work with standards like Modbus or Profibus. Making sure everything plays nicely together can save you loads of headaches and boost your overall efficiency.

Another tip: Chatting with your supplier early on is a smart move. They can offer great insights into the best VFD options tailored to your specific application—so you’re not flying blind.

Common Challenges and Solutions in VFD Implementation

Variable Frequency Drives, or VFDs for short, are pretty much a must-have in many industrial setups these days. They give you crazy precise control over motors, help save energy, and make operations run more smoothly overall. But, let’s be real—getting them up and running isn’t always a walk in the park. You can run into issues like compatibility with your existing systems, electrical harmonics causing some headaches, and making sure your team knows how to use them properly. I recently read that companies investing in VFDs saw up to 30% in energy savings—that’s pretty impressive!—but even then, they still face some bumps along the way after installation.

To sidestep some of these common problems, it’s smart to do thorough compatibility checks before you actually put the VFDs in. Making sure your team gets proper training is also a game-changer—it honestly helps things run more smoothly and cuts down on mistakes. And don’t forget about using harmonic filters—they’re great for tackling electrical distortions.

As industries push forward with digital transformation, understanding these hurdles becomes even more important. Think of it like the IBM’s AI Ladder approach—having a clear, structured plan really helps make the whole process seamless. Keeping everyone in the loop and listening to their feedback can make a big difference, helping you transition better and get the most out of your VFDs to meet industry needs effectively.

7 Best Insights on VFD 5.5kw for Industrial Applications

This chart represents the insights gathered from analyzing the VFD 5.5kw's performance across various industrial applications, highlighting common challenges and solutions faced during implementation.

Future Trends in VFD Technology for Industrial Sectors

You know, the way Variable Frequency Drives (VFDs) are evolving is really shaking up the industrial world. It’s pretty exciting because their future looks bright with a lot more efficiency and flexibility coming our way. One of the coolest trends right now is how IoT and smart tech are getting baked into VFDs. This means they can now be monitored in real-time, and even predict when maintenance might be needed before things break down. Basically, all that data can be analyzed to boost performance and cut down on unexpected downtime—that’s a huge win for lots of industries.

And let’s not forget about energy efficiency—it's all pushing innovation in how VFDs are designed and operate. The new models we’re seeing on the horizon are gonna have these fancy algorithms and machine learning capabilities that help them tweak themselves on the fly, based on how much load they’re handling or whatever’s going on. This kind of adaptability not only saves energy but also helps keep the equipment running longer, which is a win for sustainability. As industries keep pushing forward, these new tech features in VFDs are bound to change the game—making everything more productive, smarter, and more efficient. It’s pretty much a leap toward a more automated and streamlined future, don’t you think?

Maximizing Motor Efficiency and Longevity: Insights from Industry Reports on RS485 Soft Starters for 220V to 690V Applications

The quest for maximizing motor efficiency and longevity in industrial applications has garnered significant attention, especially with the advent of advanced technologies such as RS485 soft starters. Designed for voltage applications ranging from 220V to 690V, these soft starters provide a crucial function in managing motor start-up processes, thereby reducing electrical stress and enhancing performance. By incorporating a soft starter, industries can ensure smoother acceleration and deceleration of motors, which not only improves operational efficiency but also extends the lifespan of the equipment.

Among the plethora of solutions available, the SCKR1-6000 AC/AC inverter stands out as an exemplary choice for industry operators. With a robust output current range of 25A to 1600A and a triple output type, the SCKR1-6000 is engineered to handle the demanding requirements of various industrial applications. Its compatibility with RS485 communication ensures seamless integration into existing automation systems, thereby enabling real-time monitoring and control. As industries increasingly focus on optimizing resource usage, such innovative products that merge advanced technology with reliability become pivotal in driving sustainable operational practices.

FAQS

: A Variable Frequency Drive (VFD) is a device that regulates the speed and torque of electric motors by adjusting the frequency and voltage supplied to them, enabling precise control over motor performance.

VFDs enhance operational efficiency by allowing precise motor control, reducing energy consumption, and extending the life of equipment, ultimately optimizing industrial automation processes.

Common challenges in implementing VFDs include integration with existing systems, managing electrical harmonics, and ensuring proper training for personnel on VFD operation.

Organizations can overcome integration challenges by conducting thorough compatibility testing with existing systems before installation and providing comprehensive training for team members to improve operational efficiency.

The integration of IoT and smart technology in VFD systems enables real-time monitoring and predictive maintenance, optimizing operational performance and reducing downtime through data analytics.

Future VFD models are expected to incorporate advanced algorithms and machine learning capabilities, allowing them to adjust in real-time to changing load conditions and operational requirements, thus improving energy efficiency and equipment longevity.

Organizations investing in VFD technology have reported energy savings of up to 30%, as VFDs enable better control of motor speed and operations, leading to reduced energy consumption.

Training personnel on VFD operation is crucial as it enhances operational efficiency and reduces the risk of mishaps during the use of VFD technology in industrial applications.

Adapting to feedback during VFD implementation engages stakeholders and helps ensure a smoother transition and more effective use of VFDs in meeting industrial demands.

The shift towards energy efficiency is driving innovation in VFD design, with future models expected to feature capabilities that enhance real-time adaptability, thereby promoting sustainable industrial practices.

Conclusion

Hey, I read this article called "7 Best Insights on VFD 5.5kW for Industrial Applications," and I gotta say, it does a pretty good job of breaking down the basics of variable frequency drives—especially the 5.5kW kind. It kicks off by explaining what VFDs are and why they matter, mainly emphasizing how they can really boost the efficiency of industrial operations. The piece then jumps into the main features of these 5.5kW units—talking about how versatile they are across different industrial setups, which can mean big savings on energy and better performance from machinery.

It also points out some of the perks of using VFDs in factories and plants, like cutting down operational costs and giving you more control over motor systems. Plus, it walks through how to pick the right VFDs for your needs, including common hurdles folks might run into along the way and some practical tips to get around them. Toward the end, the article touches on upcoming trends in VFD tech, highlighting how Zhejiang Chuanken Electric Co., Ltd.—with over 15 years in industrial automation—is all set to play a key role in shaping the future of this field.

Honestly, it’s a solid read for anyone interested in how these drives are evolving and why they’re such a big deal in industry today.

Related Posts

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Top Strategies for Optimizing Your Operations with the Best Inverter 220V 380V VFD

-

The Ultimate Guide to Selecting the Best Vfd Controller for Your Industrial Needs

-

Essential Checklist for Choosing the Right 280kw Soft Starter for Your Business Needs

-

How to Select the Right VFD for Your 11kW Motor Applications

-

Exploring Innovative Alternatives to the Best Pump VFD for Enhanced Efficiency