Best Phase Vfd Options for Enhanced Motor Control?

Table of Contents

- Understanding Phase VFD (Variable Frequency Drives) Technology

- Benefits of Using Phase VFDs for Motor Control

- Key Features to Consider When Choosing a Phase VFD

- Top Brands and Models of Phase VFDs on the Market

- Installation and Configuration Tips for Phase VFDs

- Common Applications for Phase VFDs in Industries

- Maintenance Best Practices for Optimal Phase VFD Performance

- Market Trends and Growth Projections for 55kW VFDs: Maximizing Efficiency in 3-Phase Motor Speed Control

- FAQS

- Conclusion

- Related Posts

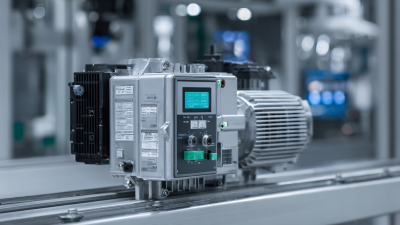

When you're dealing with industrial setups, picking the right Variable Frequency Drive (VFD) can really make a difference in how well your motors perform. If you’ve ever looked into a '1 Phase VFD,' you might notice it's often used when precise control and efficiency are top priorities. Honestly, choosing the right VFD can feel a bit daunting—there are so many options out there, and not all of them will give you the same results.

It’s a good idea to consider trusted brands like Siemens and ABB—they’re known for offering solid, reliable solutions with a variety of features. But here’s the thing: performance really depends on your specific needs. Not every motor is gonna benefit equally from a single-phase VFD, so you’ve gotta think about your particular situation.

At the end of the day, the perfect VFD can help your motor run more smoothly and even save some energy. On the flip side, all the wrong choices can lead to frustration and wasted resources. So, it’s super important to weigh all the options out there and stay open to better solutions down the line. Finding the right '1 Phase VFD' really sets the stage for better motor control and efficiency in the long run.

Understanding Phase VFD (Variable Frequency Drives) Technology

Understanding Phase VFD (Variable Frequency Drives) Technology

Variable Frequency Drives (VFDs) are crucial for motor control. They allow for precise speed regulation of AC motors, enhancing energy efficiency. Recent industry studies indicate that utilizing VFDs can lead to energy savings of up to 60% in specific applications. This is significant, considering the global push for energy-efficient technologies.

One must consider the different phase options when selecting a VFD. Single-phase VFDs are common for smaller motors. However, three-phase VFDs deliver superior performance for larger applications. Their ability to provide smoother operation reduces wear on motors, extending their lifespan. The typical lifespan of a motor can reach 20 years when managed properly.

Tips: Always evaluate your motor type before selecting a VFD. Ensure compatibility to avoid inefficiencies.

However, VFDs are not without challenges. They can introduce harmonics into the power system, affecting overall performance. Complications may arise if installations are not done correctly. Regular maintenance is vital to avoid these pitfalls. A poorly maintained VFD can become a source of frequent failures.

Tips: Establish a routine inspection schedule. This can prevent costly downtimes.

Incorporating VFD technology is a step toward modernizing industrial processes. It requires careful planning and implementation. The goal should always be to enhance efficiency while maintaining system integrity.

Benefits of Using Phase VFDs for Motor Control

Variable frequency drives (VFDs) offer numerous benefits for motor control, especially in industrial applications. According to a report by the Electric Power Research Institute, using phase VFDs can improve energy efficiency by up to 30%. This not only reduces operational costs but also extends the lifespan of the equipment. These drives enable precise control over motor speed and torque, leading to enhanced process efficiency.

Moreover, phase VFDs help in minimizing mechanical stress on motors. By allowing for smooth acceleration and deceleration, these drives reduce wear and tear on components. This can be especially important in applications that involve heavy loads. A recent study indicated that installations with VFDs experienced a 50% reduction in motor failure rates. It shows the importance of investing in quality motor control solutions.

Despite these advantages, it is vital to acknowledge potential issues. Improper setup can lead to glitches in performance. Users need to be careful during installation and modulation phases. Regular maintenance is critical for optimal performance as well. The integration of phase VFDs should be approached with a structured plan. This ensures alignment with operational goals and mitigates unforeseen challenges.

Best Phase VFD Options for Enhanced Motor Control

This bar chart illustrates the benefits of using Phase Variable Frequency Drives (VFDs) in motor control. The data reflects enhancements in efficiency, energy savings, and performance improvements based on recent studies.

Key Features to Consider When Choosing a Phase VFD

When considering a phase variable frequency drive (VFD), several key features stand out. Power rating matters significantly. Ensure the VFD can handle your motor’s specifications. A mismatch can lead to inefficient operation or even damage. Efficiency ratings offer insights into energy savings. Look for models with high-efficiency levels. This choice pays off in long-term costs.

Control options are another crucial aspect. VFDs can offer different control methods like voltage, current, or torque control. Understanding your application helps in selecting the right type. Installation ease can also affect your decision. Some VFDs come with user-friendly interfaces. This feature can save time and reduce errors during setup.

**Tip:** Always review environmental conditions where the VFD will operate. Temperature and humidity can impact performance.

Customization options can enhance functionality. Advanced VFDs allow for programming according to specific needs. However, these features can complicate user experience. It’s vital to find a balance between functionalities and usability.

**Tip:** Don’t overlook maintenance aspects. Regular checks ensure longevity and reliability, keeping your system running smoothly.

Top Brands and Models of Phase VFDs on the Market

When searching for the best phase variable frequency drives (VFDs), it’s important to consider various options available on the market. Many brands offer features like energy efficiency and advanced motor control. However, not all models are suitable for every application. Some VFDs might lack proper documentation. Others may have user interfaces that are less intuitive.

Top-rated models typically emphasize reliable performance and ease of installation. Certain options come with built-in safety features. These can prevent motor damage and enhance longevity. However, it is worth noting that not all VFDs are created equal. Some might encounter compatibility issues with certain motors. Proper research is crucial to avoid frustration later on.

Additionally, customer support can vary significantly. Some companies provide excellent assistance, while others may leave users feeling stranded. It is essential to read reviews and testimonials carefully. This can help in identifying the right fit for your needs. Features like programmability and customization can significantly improve efficiency but may require a learning curve. Always weigh the pros and cons of each choice before finalizing your decision.

Installation and Configuration Tips for Phase VFDs

When installing a phase variable frequency drive (VFD), attention to detail is crucial. Proper placement of the VFD ensures heat dissipation. Avoid tight spaces. A well-ventilated area extends the VFD's lifespan. Always check the ambient temperature. High heat can affect performance.

Wiring is another critical area. Follow appropriate color coding for wires. Ensure secure connections to prevent issues later. Use proper gauge wires based on the VFD's electrical requirements. Loose connections can cause significant problems. Always double-check before powering on.

Configuration also requires careful thought. Input voltage settings should match the motor specifications. Misconfiguration can lead to malfunction. Saving settings before adjustments can help recover from mistakes. Take the time to analyze and test settings incrementally. It helps to maintain control and reduces the risk of errors. Each small detail counts in achieving optimal performance.

Common Applications for Phase VFDs in Industries

Phase Variable Frequency Drives (VFDs) are crucial in various industries, providing enhanced motor control. These drives adjust the motor speed and torque, making them versatile for multiple applications. In manufacturing, they optimize conveyor systems, reducing energy consumption by up to 30%. In HVAC systems, Phase VFDs help maintain indoor air quality by controlling fan speeds efficiently.

In water treatment plants, they allow precise control of pumps, ensuring optimal performance and reduced wear. Data shows that plants using VFDs can decrease operational costs significantly, sometimes achieving savings up to 50%. These applications highlight the importance of VFDs in promoting sustainability while enhancing performance.

Tips: Regularly assess the performance of your VFD systems. Check for any unusual noises or vibrations. Conduct routine maintenance to extend the drive's lifespan. Investing time now can prevent costly repairs later.

Reflection is essential. Not every application needs a VFD. Sometimes, simpler solutions may suffice, so understanding your specific needs can lead to better decision-making.

Maintenance Best Practices for Optimal Phase VFD Performance

Maintaining your Phase VFD is crucial for optimal motor control. Regular inspections are essential. Check the cooling components and make sure they are free of dust. Overheating can lead to failure. Also, examine the wiring closely for any signs of wear. Corroded connections can disrupt power delivery.

Another key practice involves monitoring performance. Track parameters like voltage and frequency. Any irregularities signal potential issues. Keeping records helps identify patterns. Consider periodic calibration to ensure accuracy. This step often gets overlooked, yet it ensures peak performance.

Don't forget about environmental factors. Excessive humidity or dust can impact VFD longevity. Install protective enclosures if needed. Conducting routine cleaning is a simple task that goes a long way. Reflect on past maintenance mistakes. Each error offers lessons for improvement. Adapting a proactive approach will significantly enhance your VFD performance.

Market Trends and Growth Projections for 55kW VFDs: Maximizing Efficiency in 3-Phase Motor Speed Control

In the ever-evolving landscape of industrial automation, the demand for Variable Frequency Drives (VFDs) continues to rise, particularly for 55kW models. These devices play a critical role in enhancing the efficiency of 3-phase motor speed control systems. According to the latest market analysis, the global VFD market is projected to grow at a compound annual growth rate (CAGR) of over 6.5% from 2023 to 2030. This growth is primarily driven by the expanding need for energy-efficient solutions in industrial applications, where optimizing operational performance is crucial.

As manufacturers strive to meet increasing efficiency demands, selecting the right VFD is paramount. A model like the SCK300 offers general functionality that aligns well with various industrial applications while ensuring a seamless integration into existing systems. With an 18-month warranty, reliability and assurance are built into its design, providing users with peace of mind during their operations. Industry reports emphasize that effective motor speed control systems lead to significant energy savings, reducing operational costs by up to 30%. Therefore, investing in quality VFDs has become a standard practice for businesses aiming to enhance their production capabilities while simultaneously promoting sustainability.

Furthermore, the advancements in smart technology have allowed VFDs to incorporate features such as real-time monitoring and diagnostics, which are invaluable for predictive maintenance strategies. This capability not only helps in maximizing the lifespan of motors but also optimizes the entire system's performance. As companies look to future-proof their operations, the integration of advanced VFD solutions is becoming increasingly vital in achieving these objectives.

FAQS

: Mindfulness reduces stress and anxiety. It enhances focus and emotional well-being. You may experience improved relationships too.

Start with just five minutes of meditation. Focus on your breath. You can also engage in mindful walking or eating.

It's common to feel distracted. Sometimes, your mind wanders off. Acknowledge those thoughts without judgment and return to focus.

Yes, it boosts concentration. You may find better clarity on tasks. Daily practice can lead to increased creativity as well.

Some feel changes within a few weeks. Others may take longer. Consistent practice is key to experiencing noticeable benefits.

Group sessions can enhance the experience. You may feel supported by others. Sharing your journey can deepen your understanding.

Conclusion

The article "Best Phase Vfd Options for Enhanced Motor Control" explores the essential aspects of Phase Variable Frequency Drives (VFDs) technology and their significant advantages for motor control applications. It emphasizes the benefits of using 1 Phase VFDs, such as improving energy efficiency, reducing operational costs, and providing precise control over motor speed and torque. The guide also highlights key features to consider when selecting a Phase VFD, including compatibility, control methods, and safety standards.

Furthermore, the article discusses practical installation and configuration tips to ensure optimal performance, along with common industrial applications where Phase VFDs are instrumental. It concludes with maintenance best practices to extend the lifespan and enhance the reliability of these drives, making it a comprehensive resource for anyone looking to enhance motor control with 1 Phase VFD technology.

Related Posts

-

Best VFD for 1 Phase Motors Top Choices and Key Considerations

-

How to Effectively Utilize Electric Motor Soft Start for Optimal Performance

-

Exploring the Advantages of 10hp Vfd Over Traditional Motor Solutions

-

Innovative Vfd 200kw Solutions for Global Buyers A Comprehensive Comparison

-

Elevate Your Manufacturing Efficiency with Best Control Technique Vfd from Chinas Leading Exporter

-

Exploring 11kw Vfd Drives Prices and Trends at the 138th Canton Fair in 2025