Unleashing Efficiency: Real-World Applications of the 2 2kW VFD for Electric Motors

Table of Contents

- Understanding the Basics: What is a 2.2kW VFD and Its Importance in Motor Efficiency

- Key Benefits of Using 2.2kW VFDs in Various Industries

- Real-World Case Studies: Success Stories of 2.2kW VFD Implementations

- Energy Savings Potential: Quantifying Efficiency Gains with 2.2kW VFDs

- Installation Best Practices: Maximizing Performance of 2.2kW VFDs in Electric Motors

- Future Trends: Innovations in VFD Technology and Their Impact on Electric Motors

- FAQS

- Conclusion

- Related Posts

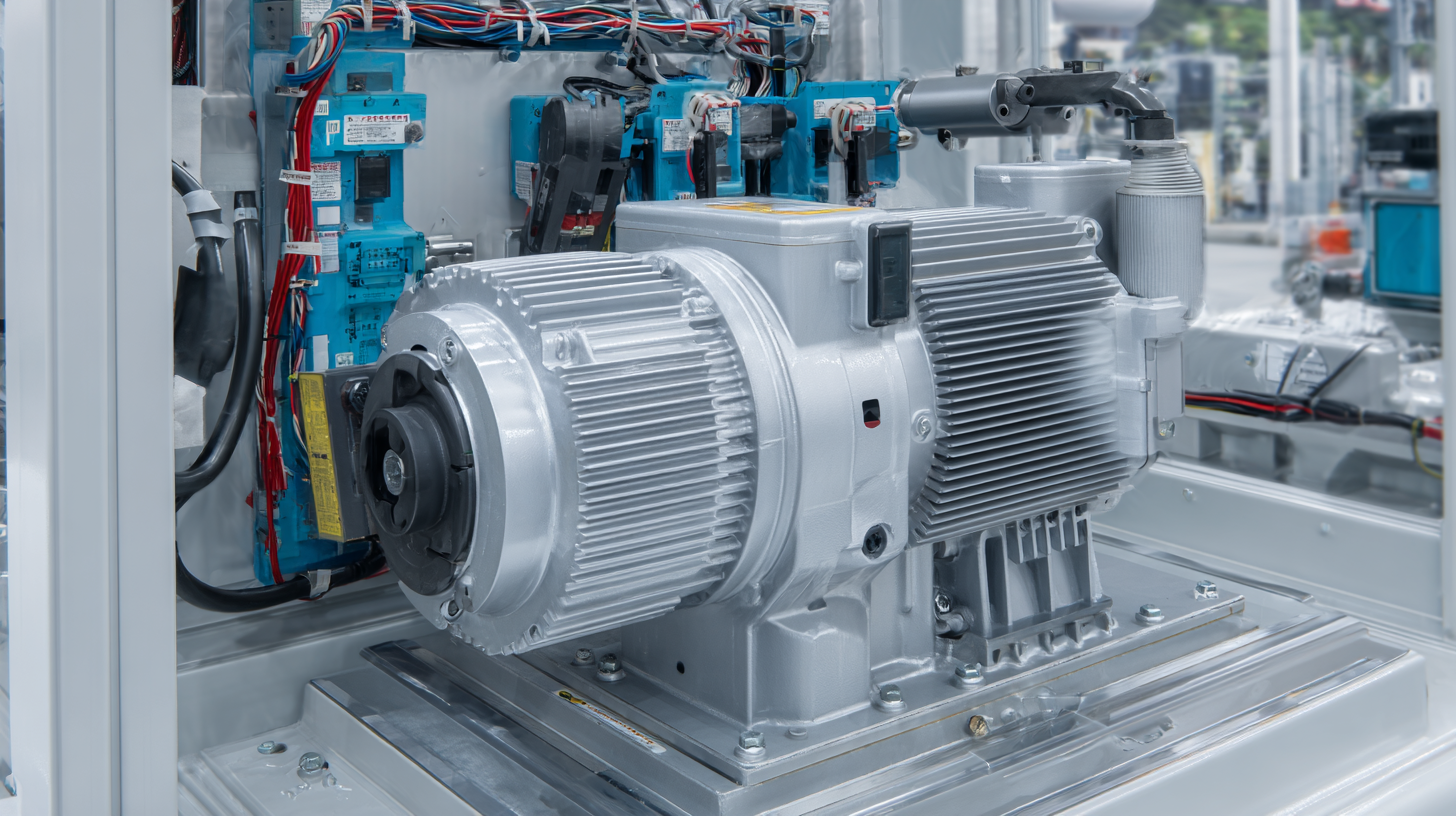

In the fast-changing world of industrial automation, keeping things efficient and performing well is more important than ever—especially when it comes to getting electric motors running smoothly. The 2 2kW VFD for Motor really shines as a game-changer. Not only does it help save energy, but it also gives you much better control over your operations.

Here at Zhejiang Chuanken Electric Co., Ltd., we’ve spent the past 15 years diving deep into developing, making, and selling automation control products. We totally get the tough challenges industries face every day. In this post, I want to share some real-world examples of how the 2 2kW VFD for Motor makes a difference—solving common problems and keeping machines running without a hitch. By harnessing the power of variable frequency drives, companies aren’t just fixing issues—they’re setting the stage for smarter, more sustainable manufacturing down the line.

Understanding the Basics: What is a 2.2kW VFD and Its Importance in Motor Efficiency

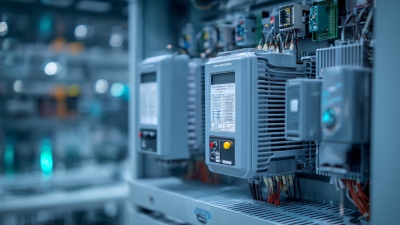

A 2.2kW Variable Frequency Drive (VFD) is truly a game-changer when it comes to electric motor technology. It helps boost the efficiency and performance of motors, giving you more control over their speed and torque. Honestly, being able to fine-tune energy use like that really makes a difference — it’s pretty much about reducing waste during operation, which is super important these days. That’s especially true for industries looking to cut down on energy costs and hit sustainability goals. Adding a 2.2kW VFD to machines—whether it's HVAC systems, conveyor belts, or other equipment—can really help streamline processes and make everything run more smoothly.

But it’s not just about saving a few bucks now and then. The market for VFDs is booming—by 2035, it’s expected to hit around $47.44 billion. That’s a lot! Plus, with a steady annual growth rate of about 5.7% from 2025 onward, it’s clear that industries are seeing the big benefits of VFDs. They’re not only saving energy but also making systems more reliable and performing better overall. All of this just shows how vital VFD technology is becoming in today’s world—helping businesses become more efficient and eco-friendly in a time when energy consciousness is more important than ever.

Key Benefits of Using 2.2kW VFDs in Various Industries

The 2.2kW Variable Frequency Drive (VFD) is really making waves across different industries, and for good reasons. It’s pretty much a game-changer because of its efficiency and versatility. Take manufacturing, for example—using these VFDs lets you control motor speed and torque with pretty great precision. That means machinery runs smoother, and you’re also saving a ton of energy. By tweaking the motor’s settings based on real-time load needs, companies can cut down on energy use while actually boosting their overall productivity.

Then, in HVAC systems, adding 2.2kW VFDs helps maintain better temperature and climate control inside big commercial buildings. They basically adjust fan and pump speeds on the fly, which makes the environment more comfortable and cuts down on energy bills. Plus, in water treatment plants, these drives are key for better flow control, which is super important for effective filtering and cleaning processes. Overall, bringing 2.2kW VFDs into these fields really pays off—saving money, improving operations, and even helping to reduce environmental impact. It’s pretty impressive how such a small component can make a big difference!

Real-World Case Studies: Success Stories of 2.2kW VFD Implementations

You know, the introduction of 2.2kW Variable Frequency Drives (VFDs) has really changed the game for electric motors in so many industries. I came across a report from the International Energy Agency that mentioned around 70% of industrial electrical energy goes into running motors. When companies started using these 2.2kW VFDs, they saw some pretty impressive results — not just saving energy but also boosting how smoothly everything runs. For example, in the HVAC world, there’s this well-known case where a big commercial building swapped out their old motor controls for 2.2kW VFDs. The result? They cut their energy use by about 30%, which saved them over $25,000 each year. Pretty sweet, right?

And it doesn’t stop there. Take the water treatment plants, for instance — one municipal facility managed to optimize their pumps by using these VFDs. They could dial the pump speeds up or down based on real-time needs, leading to a whopping 40% drop in energy consumption. Besides saving money, this also meant less wear and tear on the equipment, so the motors and pumps last longer. These stories really highlight just how powerful 2.2kW VFDs can be across different fields, not just helping the environment but also being good for business.

Unleashing Efficiency: Real-World Applications of the 2.2kW VFD for Electric Motors - Real-World Case Studies: Success Stories of 2.2kW VFD Implementations

| Application | Industry | Energy Savings (%) | Payback Period (Months) | Remarks |

|---|---|---|---|---|

| Conveyor Belt System | Manufacturing | 20% | 8 | Improved control and reduced energy consumption. |

| Pumping Station | Water Management | 30% | 6 | Enhanced efficiency and reliability. |

| CMotor Control | Textile Industry | 25% | 10 | Improved production rates with optimized speed. |

| Cooling Fan System | HVAC | 15% | 12 | A significant reduction in energy costs. |

| Extraction System | Mining | 40% | 4 | Maximized operational uptime and reduced wear. |

Energy Savings Potential: Quantifying Efficiency Gains with 2.2kW VFDs

Lately, using 2.2kW Variable Frequency Drives, or VFDs, has really become a game-changer when it comes to making industrial stuff more energy-efficient. I mean, according to a report from the U.S. Department of Energy, if you’ve got your VFDs set up right, you could cut down energy use by as much as half in electric motor systems. That’s pretty impressive, right? Basically, VFDs can tweak the motor speed to match what's actually needed. So, instead of wasting energy when the load is low, they help cut down on that wasted power, saving a bunch in the process.

And get this—there’s even a study from the International Energy Agency saying that if more industries start using VFDs, we could see a total energy saving of around 1,800 terawatt-hours worldwide by 2040. That’s not just good for the wallet, since companies would save big on costs, but it’s also great for the planet. It helps reduce the overall carbon footprint and lines up with sustainability goals that many industries are aiming for. All in all, the benefits—both financial and environmental—really highlight how important these 2.2kW VFDs are in pushing forward energy-saving efforts in electric motor applications.

Installation Best Practices: Maximizing Performance of 2.2kW VFDs in Electric Motors

When you're trying to get the most out of your 2.2kW Variable Frequency Drives (VFDs) for your electric motors, the key is really in following good installation practices. A proper setup isn't just about efficiency — it also helps the motor and VFD last longer. Start by picking a spot for installation that’s well-protected from dust, moisture, and extreme temperatures. Trust me, this small step can save you a lot of trouble down the line, like overheating or even equipment breakdowns.

Tip 1: Always check the manufacturer’s instructions when installing. That means sticking to their wiring advice and enclosure recommendations — ignoring these can lead to electromagnetic interference, which messes with your motor’s performance. And don’t forget about grounding; it’s super important for protecting delicate parts and keeping signals clear.

Tip 2: Make sure your power supply is solid. Using a dedicated circuit for your VFD can really help cut down on voltage swings and harmonics that might mess things up. On top of that, throwing in a line reactor can help handle voltage spikes, making everything run smoother and more reliably — so your motor spins at its best, without hiccups.

Future Trends: Innovations in VFD Technology and Their Impact on Electric Motors

Looking ahead, the future of Variable Frequency Drive (VFD) tech is pretty exciting — it’s heading toward some pretty groundbreaking stuff that could totally change how we think about electric motors. Thanks to advances in digital controls and machine learning, we’re starting to see VFDs that can actually tweak their performance on the fly, depending on what the motor is doing. It’s a game-changer because not only does it make things run more smoothly and efficiently, but it also helps cut down on energy waste. Basically, by automatically adjusting speed and torque to match what’s needed at any given moment, industries can get better performance without putting extra strain on those mechanical parts.

And here’s another cool trend: integrating IoT — you know, the Internet of Things — right into these drives. Modern VFDs are now coming with sensors and internet connectivity, so they can keep tabs on how the motor’s doing and how much energy it’s using, all remotely. This kind of setup allows for predictive maintenance, meaning you can catch issues early before they turn into costly problems — something that wasn’t really possible a few years back. Because of this, downtime drops and maintenance costs go down too, which means more reliable motors that last longer. As these tech things keep evolving, we’re going to see even more automation and smarter control systems. It’s really opening doors for industries to be more efficient and streamline their processes in ways we only dreamed of before.

FAQS

: A 2.2kW VFD is an electrical device that controls the speed and torque of electric motors, enhancing efficiency and performance while reducing energy consumption during operations.

They help industries lower energy costs, improve operational efficiency, and contribute to sustainability goals, as they allow precise management of motor performance.

The global market for VFDs is expected to grow significantly, reaching a value of $47.44 billion by 2035, with a compound annual growth rate (CAGR) of 5.7% from 2025 to 2035.

VFDs optimize machinery performance and energy savings by allowing for precise control over motor speed and torque, which helps in reducing energy consumption while increasing production efficiency.

In HVAC applications, 2.2kW VFDs help improve temperature regulation and climate control by modulating the speed of fans and pumps, resulting in a comfortable environment and reduced energy costs.

In water treatment facilities, VFDs facilitate better flow control, which is essential for effective filtration and treatment, thereby improving overall operational efficiency.

Best practices include selecting a location that minimizes exposure to dust and moisture, following manufacturer guidelines for installation, and using a dedicated circuit to ensure power supply quality.

Proper grounding protects sensitive components, maintains signal integrity, and helps avoid electromagnetic interference that can disrupt motor performance.

Incorporating a line reactor can help manage voltage spikes and improve system stability, ensuring the electric motor operates at peak efficiency.

The adoption of 2.2kW VFDs contributes to a reduced environmental footprint through lower energy consumption and enhanced operational efficiency, aligning with sustainability objectives.

Conclusion

In today’s industrial world, using a 2.2kW VFD for motor applications is really making a difference. Once you get the basics, it’s pretty clear how this variable frequency drive boosts motor efficiency — and let’s be honest, that’s a big deal across a bunch of industries. Some of the biggest perks? Better energy savings and more operational flexibility. Plus, there are real-life case studies showing how companies have successfully implemented these drives, which is pretty encouraging. They can even measure how much more efficient they’ve become with detailed energy savings analyses, making sure they get a good bang for their buck.

At Zhejiang Chuanken Electric Co., Ltd., we truly understand how important it is to get the most out of 2.2kW VFDs. By following best practices when installing them and keeping an eye on new trends and innovations in VFD tech, businesses can really tap into their full potential and see some serious improvements in operations. We’re dedicated to R&D and staying ahead of the curve when it comes to industrial automation products — that means our customers can feel confident embracing these advancements and making the most of what they offer.

Related Posts

-

Understanding the Common Issues Faced with Best Vfd 2.2kw in Global Procurement

-

Leading VFD Pump Controller Manufacturers from China at the 137th Canton Fair

-

Essential Checklist for Choosing the Right 280kw Soft Starter for Your Business Needs

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Top 10 VFD Drive Manufacturers from China at the 137th Canton Fair

-

Maximizing Efficiency: Essential Tactics for 1 Hp Vfd Applications in Modern Industry