5 Essential Tips for Optimizing 22kw Vfd Performance in Industrial Applications

Table of Contents

- Understanding the Basics of 22kw VFD and Its Role in Industrial Settings

- Key Factors Affecting 22kw VFD Performance and Efficiency

- Top Maintenance Practices for Enhancing VFD Reliability

- Optimizing Electrical Connections for Improved VFD Functionality

- Utilizing Control Parameters for Maximum VFD Output Performance

- Common Troubleshooting Tips to Address VFD Performance Issues

- Optimize Your Machinery Efficiency: Harnessing the Power of the General VFD 55kW 3-Phase Motor Speed Controller

- FAQS

- Conclusion

- Related Posts

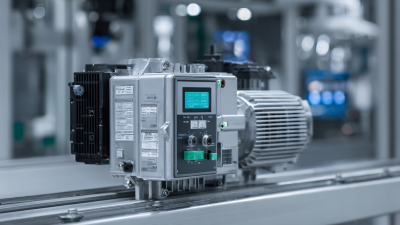

In today’s fast-changing world of industrial automation, making sure your equipment runs smoothly and efficiently is more important than ever. Out of all the components that help keep operations running, the 22kW VFD (Variable Frequency Drive) really stands out because of how crucial it is for controlling motor speed and saving energy. If you’ve been keeping an eye on the market, you might have seen reports from MarketsandMarkets saying that the global VFD market could hit around $32.91 billion by 2026, growing at about 6.2% annually—that’s pretty impressive. Here at Zhejiang Chuanken Electric Co., Ltd., we’ve been in the game for over 15 years, focusing on industrial automation products. We totally understand how important it is to get the most out of your VFDs to boost productivity and cut energy costs. In this blog, I’ll share five key tips to help you optimize your 22kW VFDs across different industrial setups. The goal? Helping your business unlock their full potential and run more sustainably—and, honestly, more smoothly too!

Understanding the Basics of 22kw VFD and Its Role in Industrial Settings

In industrial setups, a 22kW VFD (Variable Frequency Drive) is pretty much a game-changer when it comes to controlling motor speed and torque. It helps make operations more energy-efficient and precise. Honestly, understanding the basics of how a VFD works is super helpful if you want to get the most out of it. Basically, a VFD tweaks the frequency and voltage going to the motor, customizing its output to match exactly what the application needs.

To really make your 22kW VFD perform at its best, start with making sure you’ve got the right size. Using a drive that's too small can cause it to overheat or even burn out, while one that's too big might not run efficiently. Also, don’t forget to keep the firmware up to date. Manufacturers often release updates that can boost performance or squash bugs. Plus, good cooling is key — overheating can seriously ruin its lifespan and efficiency.

And hey, keep an eye on how it’s running. Using diagnostics and feedback tools to monitor the VFD can help spot issues early on. Checking out operational data regularly means you can catch problems before they turn into costly fix-ups, and avoid unnecessary downtime. If you get the basics down and follow these little tips, you'll really be able to unlock the full potential of your 22kW VFD and keep things running smoothly.

Key Factors Affecting 22kw VFD Performance and Efficiency

When you're trying to squeeze the best performance out of a 22kW Variable Frequency Drive (VFD) in an industrial setting, there are a few key things you really want to keep in mind. First off, picking the right size and type of VFD is super important. You gotta make sure it matches both the motor specs and what the application actually needs—that way, you're not running into issues like overheating or just not getting the performance you want. Using an VFD that's too big or too small? That can really mess things up and lead to inefficiencies or more maintenance down the line.

Then there’s the power supply itself. Fluctuations in voltage, harmonics, or uneven power—these can all throw a wrench in how well your VFD runs. To keep things smooth, it’s smart to add some power quality devices like filters or transformers. That way, your drive gets steady, clean power, and you avoid a lot of headaches.

And don’t forget—where you install the VFD matters, too. If it’s in a place with high temperatures, humidity, or lots of dust, it can cut down on how long the VFD lasts and how well it performs. Setting it up in a good environment really makes a difference, helping to cut down on maintenance costs and keeping everything running reliably. All in all, paying attention to these little details can really pay off in the long run!

5 Essential Tips for Optimizing 22kw VFD Performance in Industrial Applications

This chart illustrates the impact of various key factors on the performance and efficiency of a 22kw Variable Frequency Drive (VFD) in industrial settings.

Top Maintenance Practices for Enhancing VFD Reliability

When it comes to industrial setups, keeping Variable Frequency Drives (VFDs) reliable is super important to make sure electric motors run smoothly. With everyone really focusing on getting things done efficiently, it’s a good idea to stick to solid maintenance routines that actually improve VFD performance. Doing regular check-ups and keeping an eye on things proactively can make a huge difference. For example, just taking a moment to look for signs like loose wires or overheating parts can help catch issues early — way better than waiting till something breaks and causes expensive downtime.

Plus, there’s some pretty cool tech out there now, like AI and machine learning, that’s changing the game when it comes to maintenance. These tools analyze data and spot weird patterns or anomalies before problems even pop up, so you can plan maintenance only when really needed. Considering all the supply chain hiccups and labor shortages hitting the manufacturing world, being smart about maintenance isn’t just about keeping motors happy — it’s also about making sure operations keep running smoothly. As more places start adopting these smarter strategies, focusing on good VFD upkeep definitely becomes a top priority for keeping productivity high and hiccup-free.

Optimizing Electrical Connections for Improved VFD Functionality

If you're looking to get the most out of your variable frequency drives (VFDs) in industrial settings, paying close attention to the electrical connections is a must. These connections might seem simple, but they play a huge role in how well your VFD performs. When they're properly designed and kept in good shape, you’ll notice improvements in energy efficiency and less downtime. For example, making sure the connections are tight, secure, and free from corrosion can really make a difference — it helps reduce voltage drops and keeps things running smoothly. Industry reports even show that poorly maintained connections can cause energy losses of up to 10%. That just goes to show how important all those little details are!

On top of that, modern VFDs come packed with smart features that help save energy even more, which means lower operational costs. A well-tuned VFD can even hit efficiency ratings above 95%! With functionalities like load management and real-time monitoring, industries can tweak their setups to fit their specific needs while squeezing out maximum energy savings. But honestly, none of this works as well if your electrical connections aren’t up to snuff. Keeping them reliable is key to unlocking the full potential of these advanced drives and allows industries to stay ahead in today’s tough, ever-changing environment.

Utilizing Control Parameters for Maximum VFD Output Performance

Making sure your 22kW VFD runs smoothly and efficiently isn’t just something you should overlook—it's pretty key to keeping things reliable and saving energy too. Honestly, tweaking those control settings—things like acceleration, deceleration, motor type, and voltage-frequency—can really make a difference in how well your system performs.

When you fine-tune these little details, everything tends to run more smoothly, cuts down on energy waste, and even helps your equipment last longer. It’s kind of like giving your machinery the attention it deserves!

Here at Zhejiang Chuanken Electric Co., Ltd., we totally get how important precision is when it comes to industrial automation. With over 15 years of experience in designing control solutions, our team genuinely cares about helping you get the most out of your equipment.

Our latest VFD options are super customizable—you can set all the control parameters just the way you need them, so your system performs at its absolute best for your specific operations. Plus, we’re always looking to innovate with new tech and clever designs, so industries like yours can maximize performance while keeping energy use in check. We’re here to help you make the most of your machinery—no stress, just optimized performance!

Common Troubleshooting Tips to Address VFD Performance Issues

When it comes to getting the most out of your 22kW Variable Frequency Drive (VFD) in industrial setups, tackling common troubleshooting issues can really make a difference in boosting reliability and efficiency. A pretty insightful study from the Electric Power Research Institute (EPRI) found that almost 30% of downtime is due to improper settings on VFDs, which just goes to show how important routine checks and tweaks are.

One big tip is to make sure your parameter settings are spot-on. Things like maximum frequency, acceleration, and deceleration rates should be carefully matched to your load requirements. If those settings are off, you might end up with overheating, extra wear and tear, and a shorter overall lifespan for your VFD. Recent reports also highlight that nearly a quarter of VFD failures happen because of overheating, so it’s crucial to keep things cool and ensure the installation is top-notch.

Also, it’s really worth keeping an eye on input voltage and current. If these fluctuate beyond what the VFD can handle, performance can suffer and damage could occur. Regularly measuring and analyzing voltage levels can catch issues early on before they turn into costly problems. Setting up a routine maintenance schedule isn’t just a good habit — it helps keep things running smoothly and reduces unexpected breakdowns. By paying attention to these key details, your facility can enjoy more reliable VFD operation and extend the life of your equipment.

Optimize Your Machinery Efficiency: Harnessing the Power of the General VFD 55kW 3-Phase Motor Speed Controller

Optimizing machinery efficiency is crucial for maintaining productivity and reducing operational costs in any manufacturing or industrial setting. One of the most effective ways to achieve this is by utilizing advanced motor speed controllers. The SHCKELE General VFD 55kW 3-Phase Motor Speed Controller, model SCK300, is designed specifically to enhance the performance of various machinery. With an impressive warranty of 18 months, this controller not only ensures reliability but also supports the efficiency of your equipment over the long term.

The SCK300 effectively manages the speed and torque of three-phase motors, leading to better energy consumption and reduced wear and tear on machinery components. By harnessing the power of this innovative speed controller, users can fine-tune their operational parameters, allowing for smooth transitions and optimal performance across different tasks. This flexibility not only improves the overall output but also contributes to significant savings on energy bills, making the investment in such technology worthwhile.

In today's competitive market, embracing the capabilities of the SHCKELE SCK300 is essential. Its general type design makes it adaptable to a variety of applications, ensuring that it meets the unique demands of diverse industrial environments. By integrating this high-performing motor speed controller into your workflow, you can take significant steps toward optimizing your machinery and enhancing productivity while maintaining cost efficiency.

FAQS

: Control parameters in a Variable Frequency Drive (VFD) include settings such as acceleration and deceleration times, motor control type, and voltage frequency characteristics. They are important because optimizing these parameters enhances efficiency, improves reliability, and extends the lifespan of the equipment.

Fine-tuning VFD parameters ensures smoother operation, reduces energy consumption, and maximizes output performance tailored to specific operational needs.

Common causes include improper parameter settings, overheating due to incorrect configurations, and fluctuations in input voltage and current levels beyond rated limits.

Improper settings can contribute to nearly 30% of operational downtime, indicating the necessity for routine checks and adjustments to prevent performance issues.

It is essential to monitor parameter settings such as maximum frequency, acceleration, and deceleration rates, as well as ensuring adequate cooling and proper installation practices.

Scheduled maintenance allows for consistent monitoring of critical parameters and input voltage levels, helping to prevent sudden failures and ensuring seamless VFD operation.

Fluctuations beyond rated voltage levels can cause performance issues and potentially damage components, making regular voltage measurement and analysis crucial.

Nearly 25% of VFD failures are attributed to overheating, highlighting the importance of proper parameter configuration and cooling measures.

They provide high-quality, customizable VFD solutions that enable businesses to tailor control parameters for optimal output performance in their specific industrial settings.

Benefits include enhanced efficiency, increased reliability, reduced energy consumption, and prolonged lifespan of industrial equipment.

Conclusion

In today's industrial world, getting the most out of your 22kW VFD (Variable Frequency Drive) is pretty much essential for boosting efficiency and making things more reliable. Honestly, understanding the basics of what a 22kW VFD does and how it fits into different industrial setups is really the first step. Factors like matching the right motor, load type, and environmental conditions can have a big impact on how well the system performs and how efficient it is.

Good maintenance practices? Totally important if you want your VFD to keep running smoothly. Plus, paying attention to your electrical connections can make a real difference in how well everything works. Don’t forget, tweaking control settings properly can help squeeze out maximum performance, and knowing some common troubleshooting tips can save your butt if something goes wrong.

At Zhejiang Chuanken Electric Co., Ltd., we’ve been in the game for over 15 years, helping businesses get the most from their industrial automation control products, especially when it comes to 22kW VFDs. We’re all about making sure our customers can unlock the full potential of their systems without headaches.

Related Posts

-

Future Trends in VFD Market Analysis for 5.5kw Drives by 2025 with Essential Tips for Success

-

Exploring the Advantages of 10hp Vfd Over Traditional Motor Solutions

-

Elevate Your Manufacturing Efficiency with Best Control Technique Vfd from Chinas Leading Exporter

-

Discover the Top 10 Vfd Applications for Enhanced Performance and Efficiency

-

How to Optimize Your Operations with Vfd Manual Best Practices for Increased Efficiency

-

Understanding Industry Standards for Best Soft Starter Cabinet Selection Guide