The Future of Power Efficiency with Vfd 150hp Three Phase 480v Innovations

Table of Contents

- The Importance of VFD Technology in Enhancing Power Efficiency

- Challenges in Implementing VFD Systems in Industrial Applications

- Comparative Analysis: Energy Savings with 150HP VFD vs. Fixed Speed Motors

- Emerging Innovations in VFD Technology for Energy Management

- Case Studies: Successful VFD Deployments Reducing Operational Costs

- Future Trends: How AI and IoT will Transform VFD Applications

- FAQS

- Conclusion

- Related Posts

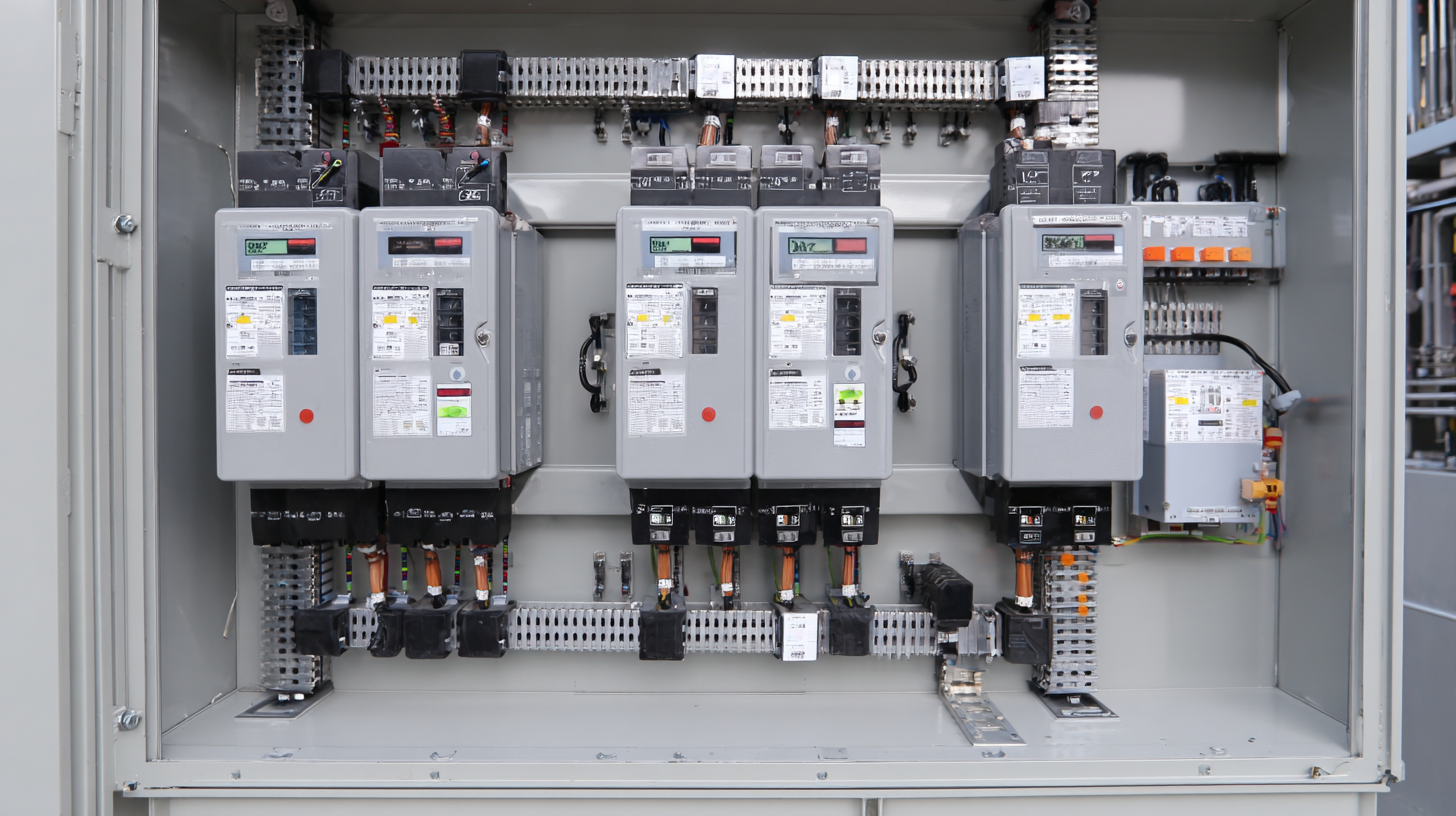

These days, with so many industries putting more emphasis on energy efficiency and going green, advanced automation tech is really stepping into the spotlight. Take the VFD 150HP Three Phase 480V, for example — it's a pretty game-changing piece of gear for variable frequency drives.

Not only does it help cut down energy use, but it also saves some serious money on operational costs. I read somewhere that the global market for these drives is expected to hit around 16.7 billion USD by 2025, growing at roughly 6.6% each year. That just shows how important it is to adopt smarter technology that helps us use power more wisely and boost performance.

Not only does it help cut down energy use, but it also saves some serious money on operational costs. I read somewhere that the global market for these drives is expected to hit around 16.7 billion USD by 2025, growing at roughly 6.6% each year. That just shows how important it is to adopt smarter technology that helps us use power more wisely and boost performance.

At Zhejiang Chuanken Electric, we’ve been in the game for over 15 years, focusing on automation control products. Our goal is to stay ahead of the curve by offering innovative solutions that are not just efficient but also reliable — all to help our clients meet and even beat industry standards.

The Importance of VFD Technology in Enhancing Power Efficiency

Variable Frequency Drives, or VFDs for short, have really changed the game when it comes to how industries handle power efficiency today. They give you pretty precise control over motor speed and torque, which means you can cut down on energy waste and save some serious money. Whether it’s for HVAC systems or big manufacturing setups, VFDs adapt the energy use of motors to what’s really needed at the moment, so you're not wasting power or overworking your equipment. It’s a pretty smart way to keep things running smoothly and efficiently.

What’s cool is that newer models, like the 150hp three-phase 480V drives, show how the industry is moving towards more eco-friendly practices. These drives don’t just boost power efficiency—they also help cut down on greenhouse gases. Plus, being able to tweak settings like load management means less stress on your machinery, which helps prolong its life and reduces maintenance costs. As industries push harder for sustainability, hopping on the VFD bandwagon isn’t just a good idea anymore — it’s pretty much a must if you want to hit those long-term energy goals.

Challenges in Implementing VFD Systems in Industrial Applications

Implementing Variable Frequency Drives (VFDs) in industrial settings isn't without its fair share of challenges. For one, the upfront costs and complicated installation process can make companies hesitant. Many factories worry about the initial investment and whether they have the right expertise to get these systems up and running smoothly. Sometimes, it even means retrofitting existing equipment, which adds another layer of complexity and can feel a bit daunting.

Plus, there's the whole thing about maintaining and understanding how VFDs work. Staff might need quite a bit of training, and that can temporarily slow things down or cause disruptions. And let’s not forget—VFDs can be pretty sensitive to electrical noise and harmonics, so you’ve got to design the system carefully to prevent any damage to motors or other gear.

All these hurdles might seem like a lot, but tackling them is pretty key if industries want to boost energy efficiency and get better overall performance. Once these challenges are managed, the benefits of VFD technology can really come into play, making it worth the effort.

Comparative Analysis: Energy Savings with 150HP VFD vs. Fixed Speed Motors

Lately, it seems like everyone in the industrial world is talking more and more about energy efficiency — and for good reason. When you really dig into the comparisons, it’s clear that using a Variable Frequency Drive (VFD) with a 150HP three-phase motor beats traditional fixed-speed setups by a mile. What’s cool about VFDs is that they let you finely tune the motor’s speed and torque to match what’s actually needed — instead of running full blast all the time. That kind of flexibility not only boosts how well everything runs, but it can also slash energy bills quite a bit — especially in situations where the workload keeps changing.

Another big bonus is how VFDs help improve the power factor, which means less wasted energy and better overall efficiency when it comes to electricity. On the flip side, fixed-speed motors just chug along at a steady speed, even if that's more than what’s really needed. In many cases, switching to a VFD can save anywhere from 20% to 50% energy. That’s a significant cut in operating costs, and it means a quicker return on investment for companies that make the switch. As more folks push for better energy performance, adopting VFD tech appears to be a smart move — helping both the environment and the bottom line at the same time.

Emerging Innovations in VFD Technology for Energy Management

As industries are really pushing to become more energy-efficient, Variable Frequency Drives (VFDs) are turning into pretty essential tools for managing power. You know, with all the new tech coming out—especially with models like the 150hp three-phase 480v systems—they're really leading the way in helping optimize energy use. These advanced VFDs don’t just tweak motor speed and torque; they also save energy by monitoring and controlling everything in real-time. That means businesses can fine-tune their operations, cut down on waste, and actually boost productivity at the same time.

Oh, and here's a little tip—make sure you keep your VFD firmware up-to-date. Those updates often include the latest efficiency tricks and new features that can really make a difference in energy management.

Plus, stuff like predictive maintenance and IoT integration is becoming a game-changer for VFDs. By analyzing data from connected devices, operators can spot maintenance needs before things break down, which means less downtime. It’s all about being proactive—so energy isn’t just tracked but constantly optimized, helping create more sustainable, smarter operations.

And another tip—set up a solid monitoring system to keep an eye on your energy use. By figuring out when your energy peaks, you can tweak your operations to use energy more wisely, making everything run smoother and more efficiently.

Case Studies: Successful VFD Deployments Reducing Operational Costs

You know, the way Variable Frequency Drives (VFDs) have changed the game in industrial automation is pretty impressive. Here at Zhejiang Chuanken Electric Co., Ltd., we’ve been shaping the future for over 15 years—creating innovative control products like our 150hp three-phase VFD at 480V. And honestly, the results speak for themselves. We've got case studies showing how these drives help cut costs and boost efficiency across all kinds of industries.

Take one of our manufacturing clients, for example. They switched to our VFD technology, and guess what? They managed to cut their energy use by about 30%. By fine-tuning motor speeds and torque, they not only sped up their production but also lowered their carbon footprint—pretty cool, right? Another story is from a water treatment plant that used our VFD systems to control pump speeds. They saved big on electricity bills but still kept everything running smoothly. All these success stories really prove how getting VFDs involved can lead to more sustainable practices and save money in the long run. It’s exciting to see how technology like this makes such a real difference!

The Future of Power Efficiency with VFD 150HP Three Phase 480V Innovations

This chart illustrates the impact of VFD (Variable Frequency Drive) deployments on operational costs across various industries. The data demonstrates the percentage of cost savings achieved after implementing VFD technology.

Future Trends: How AI and IoT will Transform VFD Applications

You know, the combo of Artificial Intelligence (AI) and the Internet of Things (IoT) is really about to shake things up when it comes to Variable Frequency Drives (VFDs), especially those big, high-power systems like the 150hp three-phase 480V drives. I came across a report from Research and Markets that estimates the global VFD market could hit around $16.2 billion by 2027 — and honestly, it’s mainly thanks to all these smart tech innovations happening now. These advances aren’t just making things more efficient; they’re also letting us monitor everything in real-time and do predictive maintenance, which means less downtime and lower operational costs overall.

With AI algorithms analyzing data from IoT-enabled VFDs, performance can be optimized automatically. For example, recent studies show that these AI-powered analytics can cut energy use by as much as 30%. Plus, because of how IoT connects everything, drives can now talk seamlessly with other machines, enabling smarter control strategies that boost system reliability. As more manufacturers start seeing the benefits of these techs, I think we’re going to see a big shift toward more energy-efficient, smart solutions in industrial automation — it’s pretty exciting stuff!

FAQS

: VFDs are devices that control the speed and torque of electric motors by varying the frequency of the electrical supply, optimizing power efficiency and reducing energy consumption.

By minimizing unnecessary power draw and optimizing motor performance according to operational needs, VFDs lead to significant reductions in energy consumption, resulting in cost savings for industries.

Key challenges include high initial costs, complexity of installation, the need for retrofitting existing equipment, and the necessity for staff training to manage and operate VFDs effectively.

Proper maintenance is crucial because VFDs can be sensitive to electrical noise and harmonics, which may damage connected equipment. Staff training ensures effective management and minimizes disruptions to productivity.

Regular firmware updates can optimize VFD performance by incorporating the latest efficiency algorithms and features, which further enhance energy savings and improve overall operational efficiency.

IoT integration allows for real-time monitoring and predictive maintenance, enabling industries to analyze data, anticipate maintenance needs, and continuously optimize energy consumption for improved operational practices.

By implementing robust monitoring systems that track energy usage over time, businesses can identify peak usage times and adjust their operations accordingly to ensure more efficient energy utilization.

Yes, VFDs can significantly lower greenhouse gas emissions by enhancing power efficiency, making them an essential component in achieving sustainable industrial practices.

Innovations include advancements in real-time monitoring, control capabilities, predictive maintenance, and IoT integration, all aimed at maximizing energy savings and enhancing operational efficiency.

Embracing VFD technology is crucial for achieving long-term energy efficiency goals and enhancing sustainability efforts within industrial operations.

Conclusion

Have you heard about the new VFD 150hp Three Phase 480V technology? It’s seriously changing the game when it comes to power efficiency in industrial setups. This advanced Variable Frequency Drive system isn’t just about cutting down energy use — it also tackles some of the big challenges companies face when trying to implement these systems. When you compare it to traditional fixed-speed motors, it’s pretty clear that VFDs can save you a ton on energy costs, which makes them an obvious choice for modern industries looking to stay competitive.

What’s even more exciting is that newer innovations in VFD tech are opening doors to even better energy management solutions. There are some pretty impressive case studies showing how companies have managed to cut operational costs, so the future looks pretty bright. Plus, with AI and IoT now starting to be integrated into these systems, we’re looking at even smarter and more efficient VFD applications. Companies like Zhejiang Chuanken Electric Co., Ltd., are definitely staying ahead of the curve in industrial automation and power savings — it’s an exciting time to be in this field!

Related Posts

-

How to Choose the Best 45kW VFD for Your Industrial Applications

-

10 Best 50hz 60hz Soft Starters for Efficient Motor Control

-

Unlocking Efficiency with the Best Rs485 Modbus Soft Starter Advantages

-

Leading Global Factory for Best 2 Phase Vfd Solutions You Can Trust

-

Unveiling the Advantages of Soft Starters in 50Hz and 60Hz Applications for Enhanced Operational Efficiency

-

5 Key Benefits of Choosing the Best VFD Pump Controller for Enhanced Efficiency