Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

Table of Contents

- Innovative VFD Technologies Revolutionizing 5.5kW Applications in 2025

- Key Industry Standards Shaping the Future of VFD Performance

- Step-by-Step Guide to Selecting the Best 5.5kW VFD for Your Project

- Exploring Energy Efficiency Improvements with Modern VFD Solutions

- Real-World Case Studies: Successful Implementations of 5.5kW VFDs

- Future Trends: What to Expect in VFD Technology Beyond 2025

- Understanding the Benefits of RS485 Soft Starters for Efficient AC Motor Control in Industrial Applications

- FAQS

- Related Posts

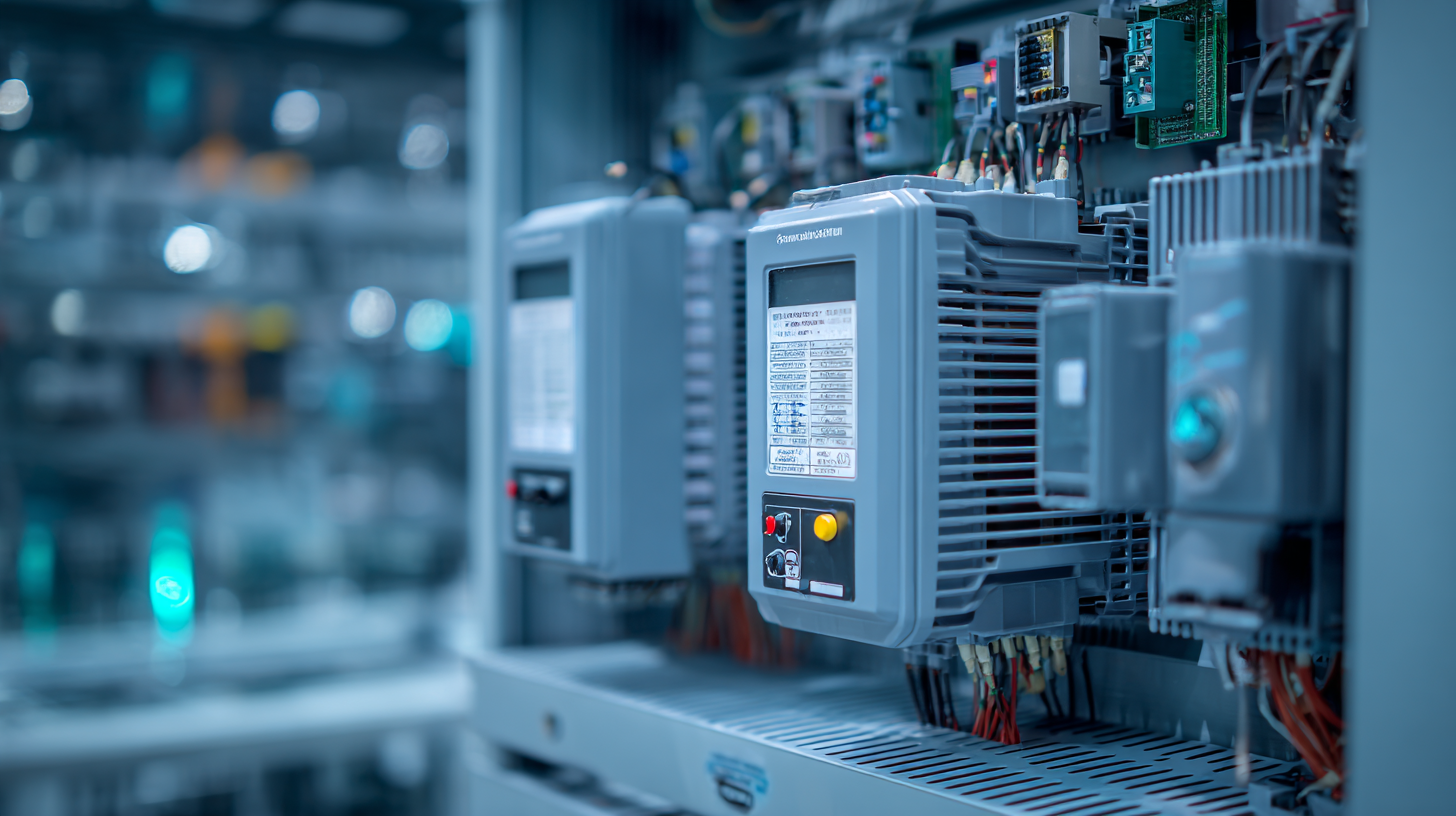

You know, with the way industrial automation is moving so fast these days, there's really a huge need for better control solutions. They're saying that the variable frequency drive (VFD) market could hit $30 billion by 2025, which is pretty mind-blowing! And products like the VFD 5.5kW are really stepping up, helping businesses save energy and work more efficiently. Take Zhejiang Chuanken Electric Co., Ltd., for example. They've been around for 15 years, cranking out top-notch automation control products, and they’re all about quality. With all the cool research and development happening, companies are finding new ways to boost productivity and sustainability in manufacturing all over the globe. As we head into 2025, I truly believe that these advanced VFD 5.5kW solutions are going to change the game across different industries, making way for a future that’s all about smart automation.

Innovative VFD Technologies Revolutionizing 5.5kW Applications in 2025

As we dive into 2025, the world of industrial automation is really starting to change thanks to some pretty cool new Variable Frequency Drive (VFD) technologies. These innovations are especially game-changing for 5.5kW applications where, let's be honest, efficiency and performance are everything. Companies like Zhejiang Chuanken Electric Co., Ltd. are leading the charge in this transformation, leaning on 15 years of know-how in creating top-notch industrial automation control products. The new VFDs are packed with smart features and energy-saving capabilities that help industries run more smoothly while also being kinder to our planet.

What’s exciting is that these latest VFD solutions aren’t just about reliability and quick response times. They’re also opening doors to integration with the Internet of Things (IoT), which means businesses can keep an eye on things in real time and even get ahead of maintenance issues before they become problems. As technology keeps moving forward, it’s giving organizations the tools they need to fine-tune their processes, cut down on energy expenses, and create a more sustainable production setup. Zhejiang Chuanken Electric Co., Ltd. is all in on pushing the limits of VFD technology, making sure their clients can tap into the full potential of these advanced systems to tackle whatever the future throws at them.

Key Industry Standards Shaping the Future of VFD Performance

You know, as industries keep evolving, Variable Frequency Drives, or VFDs, are really taking center stage when it comes to boosting operational efficiency and saving on energy costs. Looking ahead to 2025, we’re on the brink of a whole new chapter in VFD performance thanks to some key industry standards focusing on efficiency, interoperability, and sustainability. One exciting thing to note is that improvements in communication protocols and energy regulation standards are going to have a big impact on the next generation of VFDs. This means they’ll blend in much more seamlessly with smart manufacturing systems, which is pretty cool.

Plus, with the growing push for eco-friendly technologies, manufacturers are increasingly going to adopt standards that not only cut down on energy use but also keep environmental impact to a minimum. When we talk about enhanced efficiency ratings and better power factor correction, it’s not just about checking boxes for regulations—these advancements can really help businesses save a ton of money.

As companies try to future-proof their operations in this fast-paced tech landscape, it’ll be super important to stay updated on these shifting standards to really tap into the benefits of 5.5 kW VFD solutions. All in all, this move towards high-performance VFD systems is going to be pivotal for pushing industrial automation and sustainability forward in the coming years.

VFD Performance Metrics Over the Years

Step-by-Step Guide to Selecting the Best 5.5kW VFD for Your Project

As we look ahead to 2025, picking the right Variable Frequency Drive (VFD) for your 5.5kW project is super important if you want to squeeze out the best efficiency and performance. Trust me, a good VFD can do wonders—it can optimize your energy usage, boost system reliability, and even help your equipment last longer than you'd expect. So, let’s dive into this step-by-step guide to help you make a smart choice that keeps you in sync with the latest VFD innovations.

First things first, take a moment to think about what you really need for your operation. Consider stuff like load requirements, the environment where it'll be used, and how well it can integrate with your current system. You’ll want to look for VFDs that are packed with cool features, like energy-saving algorithms, temperature monitoring, and communication interfaces that will play nicely with your existing control systems. And hey, don’t forget to check out customer reviews and see what kind of technical support is out there—these can give you a good idea about how reliable a VFD might be.

Next, make sure you’re on the right side of the law by checking out the relevant standards and regulations. It’s a good idea to research manufacturers who stick to industry specs—this not only helps you get quality gear but also boosts the safety and efficiency of your setup. Oh, and here’s a pro tip: think about scalability. Go for a VFD that can handle future upgrades because, let’s face it, technology moves fast, and you want your project to keep up and really shine.

Exploring Energy Efficiency Improvements with Modern VFD Solutions

You know, energy efficiency has really taken center stage in the industrial world lately. It’s no wonder that Variable Frequency Drives, or VFDs as everyone calls them, have become such crucial players for boosting performance while slashing energy use. I mean, did you see that report from the U.S. Department of Energy? It says that in some motor-driven applications, VFDs can cut energy consumption by up to a whopping 50%. And looking ahead to 2025, we can expect even more groundbreaking improvements in VFD tech, thanks to smarter algorithms and new features that adjust to what’s going on in real-time.

One cool trend to keep an eye on is the rise of smart VFDs. These bad boys can talk to other system components, which means we get real-time data at our fingertips for better energy management. A study from the International Energy Agency found that implementing these smart technologies in motor systems can save anywhere between 10 to 30% on energy. That’s not just good news for your budget; it’s a win for our planet, too.

Tip 1: Don't forget to keep an eye on how your VFD systems are performing to spot any inefficiencies. Updating the software can really boost functionality and help you save even more energy.

Tip 2: If you’ve got some older motor systems, think about retrofitting them with the latest VFD technology. It’s a smart move to stay energy-efficient and competitive.

Tip 3: And hey, chat with your suppliers! See what customizable VFD solutions they have that could fit your energy needs and operational goals perfectly.

Real-World Case Studies: Successful Implementations of 5.5kW VFDs

In today's rapidly evolving technological landscape, Variable Frequency Drives (VFDs) have emerged as pivotal components in enhancing operational efficiency across diverse industries. The implementation of 5.5kW VFD solutions is a testament to this evolution, showcasing significant reductions in energy consumption and operational costs. Real-world case studies illustrate how businesses are leveraging these advancements to streamline their processes.

For example, a manufacturing plant recently integrated a 5.5kW VFD into their conveyor systems, leading to a 25% decrease in energy usage while improving motor performance and extending equipment lifespan.

Another striking case involves a water treatment facility that adopted a 5.5kW VFD to optimize pump speed and flow rates. This implementation not only facilitated smoother operations but also enabled real-time adjustments based on fluctuating water demand. The results were impressive, with the facility reporting enhanced control, lower maintenance expenses, and a substantial reduction in its carbon footprint.

These implementations underscore the transformative potential of VFD technology, particularly as we look toward a future where energy efficiency and sustainability are paramount considerations for industries worldwide.

Future Trends: What to Expect in VFD Technology Beyond 2025

As we look ahead to the future of Variable Frequency Drive (VFD) technology beyond 2025, there’s a ton of exciting stuff brewing. Industrial automation keeps evolving, and it’s really setting the stage for smarter, more efficient systems. We’re seeing trends like the greater use of artificial intelligence, improved energy efficiency, and better communication protocols that are totally going to change the game for how VFDs function. Thanks to these innovations, we’ll be able to do real-time monitoring and predictive maintenance, which is pretty awesome because it means less downtime and lower operational costs.

At Zhejiang Chuanken Electric Co., Ltd., we’ve been all about pushing the envelope in industrial automation for the last 15 years. This journey puts us in a great spot to take advantage of these new trends coming our way. Our commitment to R&D keeps us ahead of the game, making sure our VFD solutions tackle today's challenges while also being ready for the tech advancements down the road. As we gear up to integrate these next-gen features, we’re dedicated to giving our customers state-of-the-art solutions that really help them unleash their operational potential in this ever-more automated world.

Understanding the Benefits of RS485 Soft Starters for Efficient AC Motor Control in Industrial Applications

Soft starters are increasingly recognized for their role in improving the efficiency and longevity of AC motors in industrial applications. The RS485 communication protocol integrated into soft starters enhances their ability to provide smooth acceleration and deceleration, minimizing mechanical stress and energy consumption. According to industry reports, implementing soft starters can reduce start-up currents by up to 70%, significantly lowering the risk of electrical interference and wear on motor components.

One exemplary product in this field is the SCKR1-6000 AC/AC Inverter, which supports output currents ranging from 25A to 1600A. This model's triple output type allows for versatile applications, providing users with the capability to efficiently control multiple motors simultaneously. With its advanced features, the SCKR1-6000 helps to streamline operational workflows while ensuring safety and reliability. Reports indicate that systems employing such advanced soft start technology can lead to energy savings of approximately 30%, underscoring the economic advantages of adopting RS485 soft starters in various industrial settings.

Additionally, the RS485 interface facilitates enhanced monitoring and diagnostics, crucial for modern industrial environments. This allows operators to proactively address potential issues, further preventing downtime and ensuring precise control over motor behaviors. As industries continue to pursue automation and efficiency, the integration of RS485 soft starters like the SCKR1-6000 will play a pivotal role in achieving operational excellence and sustainability.

FAQS

: VFDs are essential tools for optimizing operational efficiency and energy consumption in industries. They allow for control of motor speed and torque, contributing to improved performance and reduced energy usage.

According to the U.S. Department of Energy, VFDs can reduce energy consumption by up to 50% in certain motor-driven applications.

Key industry standards emphasizing efficiency, interoperability, and sustainability are anticipated to drive advancements in VFD technology by 2025. This includes improvements in communication protocols and energy regulation standards.

Smart VFDs communicate with other system components for real-time data analysis and energy management, potentially leading to energy savings of 10-30%, according to the International Energy Agency.

Companies can stay abreast of evolving standards by regularly monitoring VFD performance, implementing software updates, and considering retrofitting older systems with modern VFD technology.

Anticipated trends include increased integration of artificial intelligence, enhanced energy efficiency, and improvements in communication protocols, which will allow for real-time monitoring and predictive maintenance.

Retrofitting older motor systems with modern VFD technology can help capitalize on energy-efficient advancements, ensuring competitive edge and compliance with regulatory requirements.

Engaging with suppliers can lead to the exploration of customizable VFD solutions that align with specific energy requirements and operational goals, enhancing overall system performance.

Researching and developing VFD solutions is crucial for companies to stay ahead of technological advancements, ensuring that their systems meet current challenges and are ready for future innovations.

Related Posts

-

Understanding the Common Issues Faced with Best Vfd 2.2kw in Global Procurement

-

How to Choose the Best 45kW VFD for Your Industrial Applications

-

The Ultimate Guide to Selecting the Best Vfd Controller for Your Industrial Needs

-

5 Essential Tips for Choosing the Best Bypass Soft Starter

-

Understanding Industry Standards for Best Soft Starter Cabinet Selection Guide

-

Leading Global Factory for Best 2 Phase Vfd Solutions You Can Trust