Future Trends in VFD Market Analysis for 5.5kw Drives by 2025 with Essential Tips for Success

Table of Contents

- Future Market Landscape for 5.5kW VFD Drives by 2025

- Key Technological Advancements Influencing VFD Development

- Emerging Applications and Industries Driving VFD Demand

- Strategies for Businesses to Thrive in the VFD Market

- Challenges and Solutions for Adopting VFD Technology

- Sustainability Trends Shaping the Future of VFD Solutions

- Maximizing Energy Efficiency: Insights from Industry Reports on Soft Starters for AC Motors in High-Voltage Applications

- FAQS

- Related Posts

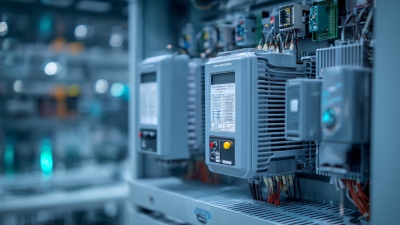

You know, the Variable Frequency Drive (VFD) market is really expected to grow quite a lot in the next few years, especially when it comes to drives around 5.5kW. If you’ve been keeping an eye on industry news, you’ll see reports suggesting that the global VFD market might hit about USD 18 billion by 2025. A big reason for this is the rising demand for energy-efficient solutions across different industries. Companies are all about improving their operations without wasting energy, and that’s where 5.5kW VFDs come into play—they’re pretty much essential in modern industrial automation.

Take Zhejiang Chuanken Electric Co., Ltd., for example. They’re a high-tech company with 15 years under their belt, focusing on R&D, manufacturing, and selling automation control products. They really understand how crucial this trend is. By keeping up with the latest tech and market needs, businesses can tap into the full power of VFDs—making their processes more efficient and driving sustainable growth for the future.

Future Market Landscape for 5.5kW VFD Drives by 2025

Looking ahead to 2025, the market for 5.5kW VFDs—those variable frequency drives—is expected to go through some pretty exciting changes. Thanks to advances in tech and a growing push for energy savings, this segment is really shaping up. A recent report from Markets and Markets mentioned that the global VFD market could hit around $28 billion by then, growing at a steady rate of about 6.8% annually. We're seeing more industries—like manufacturing, automotive, and HVAC—grabbing onto these drives since they’re such crucial tools for controlling motors efficiently.

When we look at the market split, the industrial sector is set to take the biggest piece—probably about 40% of the market share by 2025. That’s mainly because automation in factories is becoming more common, and there’s a clear need for energy-efficient tech to keep things running smoothly. Plus, the whole trend of integrating IoT and smart tech into VFDs is really taking off, making operations more efficient and slashing energy use. As companies become more eco-conscious and try to cut down their carbon footprints, the demand for 5.5kW drives with these nifty features will definitely pick up. It’s a pretty exciting time for players in the market, no doubt about it.

Key Technological Advancements Influencing VFD Development

By 2025, the Variable Frequency Drive (VFD) market is really set to shake things up, thanks to some pretty exciting tech breakthroughs that are shaping how VFDs develop. One of the coolest innovations is how IoT (that’s the Internet of Things) is now being integrated into these systems. Basically, it means you can monitor and control motor performance in real-time — making energy use more efficient and troubleshooting way easier. As companies try to optimize their operations, these smart VFDs can actually predict maintenance needs before things break down, cutting down on downtime and saving money in the long run.

On the tech front, there's also been big progress with power semiconductors. Materials like silicon carbide (SiC) and gallium nitride (GaN) are totally changing the game when it comes to how efficiently VFDs convert power. They support higher switching speeds and better heat management, which is a huge plus, especially for smaller drives in the 5.5kW range. Moving towards these advanced semiconductors doesn’t just make the drives better — it also helps with sustainability, since they waste less energy and produce less heat.

Plus, improvements in digital signal processing (DSP) are allowing for more advanced control algorithms. That means VFDs can be way more precise and responsive across different applications. They can even adapt to changing load conditions on the fly, boosting efficiency and helping extend equipment lifespan. Looking ahead to 2025, these tech innovations are going to be a big deal for businesses wanting to stay ahead in the VFD game — no doubt about it.

Emerging Applications and Industries Driving VFD Demand

You know, as new applications and industries pop up, the demand for variable frequency drives (VFDs) is really skyrocketing, especially in the 5.5 kW range. More and more industries are jumping on the energy-efficient bandwagon, and VFDs are becoming a key part of sectors like manufacturing, HVAC, and renewable energy. It’s not just about going green—these drives actually help save a bunch of money too, by optimizing how motors run and cutting down on energy waste.

In North America, the market’s getting a serious boost from cutting-edge tech like the Industrial Internet of Things (IIoT) and Industry 4.0. Companies are investing in smarter automation and better connectivity, which means they can monitor and control their drive systems in real time. This not only makes operations smoother and more efficient but also sparks new ideas for system design and maintenance. Looking ahead, the market’s expected to grow from around $4.5 billion in 2025. Businesses that jump on these trends early are likely to lead the charge, gaining a real edge in VFD usage and setting the stage for future success.

Strategies for Businesses to Thrive in the VFD Market

The VFD market's really booming these days, especially as more businesses are keen on cutting down energy use and saving on operational costs. If you want to stay ahead in this crowded space, it’s super important for companies to adopt smart strategies that match what customers need now—and keep up with the latest tech trends.

One solid piece of advice? Invest in cool, innovative tech that boosts the performance and efficiency of variable frequency drives. Keeping an eye on what's new and upcoming can actually give you a real edge over the competition. And don’t forget, partnering up with other companies can open doors to new markets and customers—just look at recent collaborations aimed at helping small and medium-sized businesses succeed.

Oh! And really, organizations should also focus on sustainability and social responsibility. Getting involved in initiatives that support marginalized groups—like women-led businesses—not only boosts your brand image but can also lead to new opportunities. By weaving these kinds of strategies into your business game plan, you’ll be more likely to stay relevant and thrive in the growing VFD market as we head toward 2025.

Challenges and Solutions for Adopting VFD Technology

You know, adopting Variable Frequency Drive (VFD) tech in the marine world isn’t exactly a walk in the park right now. There’re quite a few hurdles, especially when it comes to fitting these systems into ships and offshore platforms we already have in place. Plus, training the crew to actually use and maintain these systems isn’t straightforward, and folks are a little worried about how reliable VFDs are in those tough marine environments. On top of that, market demand can be pretty unpredictable, and navigating the often complicated regulatory rules doesn’t help either. All this can slow down or even block progress.

To get past these bumps, companies really need to invest in good training programs and run serious testing to make sure everything works right. Using simulation tools and trying out pilot projects first can also give a good idea of whether VFDs will fit into their operations without surprises. With the global market for VFDs expected to hit around $32 billion by 2025, tackling these challenges head-on is crucial if businesses want to truly unlock the benefits—like better efficiency, lower energy costs, and doing their part for the environment. Ultimately, getting these things right could make a huge difference for the future of maritime operations, making them more sustainable and cost-effective in the long run.

Sustainability Trends Shaping the Future of VFD Solutions

You know, the way Variable Frequency Drive (VFD) technology is evolving these days is really becoming linked to sustainability efforts across a bunch of industries. Companies are trying to cut down their carbon footprints, and VFDs play a huge role in helping with energy efficiency. They do this by fine-tuning motor control and reducing energy use during operation. Not only do they boost performance, but they also seriously help companies hit their green goals. Plus, with the push for eco-friendly practices, manufacturers are now building VFDs with cool features like predictive maintenance and real-time energy monitoring—making it easier for businesses to stay sustainable.

And it doesn’t stop there. With renewable energy—like wind and solar—taking center stage, the market for VFDs is changing fast. There's a high demand for drives that can handle the inconsistent nature of these energy sources. Companies working on VFDs that work well with renewables are definitely ahead of the game. If they pour resources into R&D to come up with innovative, environmentally friendly VFDs, they’ll not only meet all the new regulations but also attract customers who really care about the planet. That’s a smart move for staying competitive in a world that's getting more and more eco-conscious, don’t you think?

Future Trends in VFD Market Analysis for 5.5kw Drives by 2025

| Parameter | 2023 Estimation | 2025 Projection | Growth Rate (%) |

|---|---|---|---|

| Market Size (Million USD) | 500 | 700 | 40% |

| Installed Base (Units) | 20,000 | 30,000 | 50% |

| Energy Efficiency Improvement (%) | 5% | 10% | 100% |

| Sustainability Adoption Rate (%) | 15% | 35% | 133% |

| Market Share of Eco-friendly VFDs (%) | 10% | 25% | 150% |

Maximizing Energy Efficiency: Insights from Industry Reports on Soft Starters for AC Motors in High-Voltage Applications

When it comes to maximizing energy efficiency, particularly in high-voltage applications, soft starters for AC motors are a crucial component. These devices enable a smoother and more controlled start-up for motors, reducing the inrush current and minimizing mechanical stress on the system. Industry reports highlight the significance of soft starters in ensuring operational reliability while enhancing energy savings, making them an essential investment for businesses focused on sustainability and cost-effectiveness.

One standout product in the market is the SCKR1-6000 AC/AC Inverter, which is designed to deliver robust performance across various applications. With an output current ranging from 25A to 1600A, this model accommodates a variety of operational demands, making it versatile for different high-voltage needs. Its triple output type configuration ensures consistent power delivery, which is vital for maintaining efficiency in complex systems. By integrating such advanced inverters with soft starters, facilities can optimize their energy consumption and significantly reduce operational costs over time.

Moreover, the use of innovative technology in devices like the SCKR1-6000 not only enhances energy efficiency but also contributes to prolonged equipment life. This is particularly important in industrial settings where downtime can be costly. The ability to manage motor starts and stops more effectively leads to reduced wear and tear, thereby improving the overall maintenance schedules and minimizing unexpected disruptions. Investing in quality soft starters and reliable inverters is a strategic move for any organization looking to enhance its energy performance in high-voltage applications.

FAQS

: Key advancements include the integration of IoT capabilities for real-time monitoring, evolution of power semiconductor technology using materials like silicon carbide and gallium nitride, and improvements in digital signal processing for sophisticated control algorithms.

IoT integration allows for real-time monitoring and control of motor performance, leading to enhanced energy efficiency, easier troubleshooting, and predictive maintenance, which reduces downtime and operational costs.

New materials such as silicon carbide (SiC) and gallium nitride (GaN) improve power conversion efficiency, facilitate higher switching frequencies, and enhance thermal management, supporting compact, high-performance VFD designs.

Businesses should invest in innovative technologies, form strategic partnerships to access new markets, and prioritize sustainability and social responsibility to enhance brand reputation and ensure relevance.

Challenges include integration into existing infrastructure, the need for specialized operator training, reliability concerns in harsh conditions, and fluctuations in market demand and regulatory compliance.

Solutions include comprehensive training programs, robust testing protocols, and utilizing simulation tools and pilot programs to assess feasibility before full-scale deployment.

The global variable frequency drive market is projected to grow significantly, with revenue expected to reach $32 billion by 2025.

Stakeholders can focus on rigorous testing protocols and training programs to ensure the reliability of VFD systems in challenging marine conditions.

Prioritizing sustainability enhances brand reputation and opens diverse opportunities, allowing companies to align with evolving customer demands and societal responsibilities.

Adaptive control strategies improve the precision and responsiveness of VFDs under changing load conditions, bolstering efficiency and extending the lifespan of equipment.

Related Posts

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Exploring Global Trade Opportunities with the 15kw Vfd at the Successful 137th Canton Fair

-

Step-by-Step Guide to Sourcing the Best China VFD for Your Business Needs

-

Unlocking Efficiency with the Benefits of the Best Pressure Booster Vfd Technology

-

10 Secrets to Finding the Best Chuanken Soft Starter for Your Business Needs

-

10 Best 50hz 60hz Soft Starters for Efficient Motor Control