2026 How to Choose the Best VFD Drive Manufacturers?

Table of Contents

- Understanding VFD Drives: Basics and Applications in Industry

- Key Factors to Consider When Selecting VFD Drive Manufacturers

- Evaluating the Reputation and Experience of VFD Manufacturers

- Analyzing the Technical Specifications of VFD Drives

- Importance of After-Sales Support and Warranty in VFD Selection

- Cost vs. Quality: Balancing Your Budget When Choosing VFD Drives

- Examining Industry Certifications and Compliance for VFD Products

- Exploring Efficiency: The Impact of General VFD 55kw 380V Motor Speed Controllers on Operational Performance in Industrial Applications

- FAQS

- Conclusion

- Related Posts

Picking the right VFD drive manufacturer can honestly feel pretty overwhelming. I mean, with the industry expected to hit around $20 billion by 2026, there are tons of options out there, each a little different. When you're making a choice, things like efficiency, reliability, and the latest tech really matter—and it's easy to get lost in the shuffle.

Lately, big players like Siemens, Schneider Electric, and Allen-Bradley have pretty much taken over the market. Their products tend to promise better performance and last longer. But, let’s be real, not every option suits every situation. Some companies might offer lower prices, but that often comes at the expense of quality. It’s super important to know what kind of reputation each manufacturer has.

Looking at customer reviews and industry reports can really help you see how these drives perform in real life. Some brands might do great in one type of application but not so hot in another. So, it’s all about carefully thinking through what you actually need. At the end of the day, the best choice balances good quality, solid support, and being easy on the wallet. Yeah, figuring all this out is a bit tricky, but it’s absolutely worth the effort to make a smart decision in this constantly changing field.

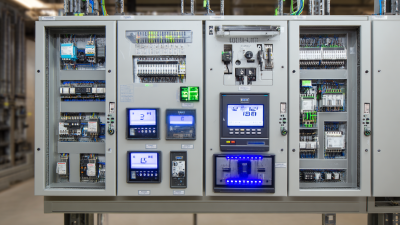

Understanding VFD Drives: Basics and Applications in Industry

Variable Frequency Drives (VFDs) are essential in various industries today. These devices control the speed and torque of electric motors. They enhance energy efficiency, leading to significant cost savings. According to a report from the U.S. Department of Energy, using VFDs can reduce energy consumption by 20%-50%. This is crucial for manufacturers striving for operational efficiency.

Industries like HVAC and manufacturing heavily rely on VFDs. In HVAC systems, VFDs adjust motor speeds based on real-time demand. This adaptability results in better temperature control and energy savings. A study by the Electric Power Research Institute indicates that implementing VFDs in HVAC can result in energy savings of up to 25%. However, not all applications benefit equally. Some systems might need constant speed, making VFDs less effective. It’s vital to assess each application’s requirements.

The application of VFDs isn't straightforward. While their advantages are significant, potential drawbacks exist. For example, harmonics generated by VFDs can affect power quality. These complications necessitate careful planning and installation. Manufacturers must weigh the benefits and challenges before implementation. Insightful consideration can lead to a more optimized approach.

Key Factors to Consider When Selecting VFD Drive Manufacturers

When choosing the best VFD drive manufacturers, several key factors come into play. Reliability is crucial. A well-made drive reduces downtime. Look for manufacturers with a solid track record. Reviews and client feedback can offer insights into performance.

Another important aspect is the availability of technical support. A knowledgeable support team can help troubleshoot problems quickly. This can save time and money. Ensure the manufacturer provides comprehensive documentation. Good manuals help users understand complex features.

Additionally, consider customization options. A one-size-fits-all approach may not suit every application. Look for manufacturers willing to tailor solutions to your needs. However, be wary of overly complicated products. Sometimes simpler designs work better in practice. Balancing complexity and usability is essential for lasting effectiveness.

Evaluating the Reputation and Experience of VFD Manufacturers

When selecting a VFD (Variable Frequency Drive) manufacturer, reputation and experience are critical factors. Manufacturers with a solid track record usually provide reliable products. Look for companies that have been in the industry for years. Longevity often indicates stability and knowledge. However, don’t overlook newer companies; they sometimes bring innovative solutions.

Tips: Check customer reviews. They reveal how well a manufacturer meets client expectations. Reach out to current and previous customers for insights. Positive feedback is a good sign, but negative reviews can be more telling. Understand any recurring issues mentioned.

A manufacturer’s experience in your specific application is vital. They should understand your industry’s unique needs. Evaluate their project history closely. A variety of projects can indicate versatility. However, be cautious; not all past projects reflect current capabilities. Ask about updates in technology and practices.

Tips: Engage in conversations with manufacturers. Their willingness to share knowledge shows their commitment to quality. Pay attention to their responsiveness. A good manufacturer will take time to answer your questions thoroughly.

Evaluation of VFD Manufacturers Based on Key Criteria

This chart illustrates the evaluation scores of various criteria important in selecting VFD manufacturers, including customer reviews, industry experience, technical support, product variety, and pricing. The scores represent the confidence level in each criterion contributing to the overall reputation of the manufacturers.

Analyzing the Technical Specifications of VFD Drives

When choosing a Variable Frequency Drive (VFD), technical specifications are crucial. Analyzing these can reveal the drive's true capabilities. For instance, the efficiency ratings of drives can vary significantly. A report from the Electric Power Research Institute notes that the efficiency of VFDs can range from 95% to over 98%. This difference can significantly impact energy savings over time.

Another key specification is the voltage rating. Drives typically come in low voltage (up to 690V) or medium voltage (1 kV to 3 kV). Selecting the right voltage rating is essential for optimal performance and longevity. Too high a voltage could lead to unnecessary energy losses. A study indicates that many facilities overlook this detail, leading to complications and additional costs.

Moreover, the control method of the VFD is important. Some drives use sensorless vector control, while others use PWM (Pulse Width Modulation). Each method has pros and cons. Sensorless control might seem simpler but can lack precision in applications requiring high torque. Many users report frustration due to mismatches between their application needs and the control method of the VFD. Careful assessment is needed to avoid costly mistakes in selecting the right VFD specifications.

Importance of After-Sales Support and Warranty in VFD Selection

When selecting a Variable Frequency Drive (VFD), after-sales support and warranty play crucial roles. According to industry reports, nearly 30% of users experience issues within the first year of operation. A reliable warranty can safeguard against unexpected failures, ensuring system resilience. A strong after-sales service enhances user confidence. Manufacturers with established support networks are often preferred.

Tips: Evaluate the warranty period offered by various manufacturers. Look for options that provide extensive coverage. A longer warranty can signal better build quality.

Consider the availability of technical support. Some manufacturers provide 24/7 assistance, which can be a game-changer during emergencies. Investigate user reviews to gauge responsiveness. Reacting swiftly to queries can alleviate stress in critical moments.

It’s essential to reflect on your operational needs. A manufacturer’s support offerings should align with your expectations. An excellent warranty might not compensate for poor service quality. Balancing these factors is vital to ensure long-term satisfaction with your VFD choice.

Cost vs. Quality: Balancing Your Budget When Choosing VFD Drives

When selecting VFD drives, balancing cost and quality is crucial. Some manufacturers offer low prices, tempting many buyers. However, these cost-effective options may compromise performance. It’s essential to assess your specific needs. For instance, a low-cost drive might not meet the requirements for heavy-duty applications. Can you afford such risks?

Quality varies significantly among manufacturers. Some brands invest heavily in research and development. This leads to advanced technology that enhances performance and reliability. Still, high-quality drives come at a price. Balancing this with your budget can be challenging. Do you prioritize longevity or initial cost? Every dollar spent today could impact future maintenance expenses.

Consider the long-term benefits when making your choice. Sometimes, opting for a slightly more expensive drive saves money in the long run. A reliable VFD drive enhances efficiency and productivity. It’s worth reflecting on how critical your application is. Short-term savings might lead to higher costs down the road.

Examining Industry Certifications and Compliance for VFD Products

When selecting a Variable Frequency Drive (VFD), industry certifications and compliance are key factors. Many studies show that certified VFDs ensure optimal performance and reliability. For instance, compliance with IEC 60034 standard is crucial. This standard assures that products meet global safety and efficiency benchmarks. Without these certifications, you may encounter unnecessary risks.

Tips: Always ask for certification documents. Verify the compliance of the VFD with international standards. This not only enhances safety but also improves system efficiency.

Moreover, industry reports indicate that up to 30% of VFD failures are linked to non-compliance. Choosing manufacturers who adhere to regulations significantly reduces operational hiccups. Even small details, like proper installation guidelines, can make a difference.

Tips: Evaluate the manufacturer’s quality assurance process. A transparent process indicates a commitment to reliability. Overlooked factors could lead to costly repairs down the line.

Exploring Efficiency: The Impact of General VFD 55kw 380V Motor Speed Controllers on Operational Performance in Industrial Applications

The use of motor speed controllers has become increasingly integral in enhancing operational efficiency within industrial settings. Specifically, general VFD motor speed controllers, like those designed for 55kw 380V applications, offer significant advantages by allowing precise control over motor speed and torque. This adaptability not only optimizes energy consumption but also contributes to smoother operation, minimizing wear and tear on machinery, which is essential for maintaining productivity in a competitive environment.

In particular, a robust model designed for general use can provide considerable benefits across various industries. A warranty period of 18 months serves to underscore the reliability and durability of these controllers, giving operators confidence in their investment. By employing such technology, industries can achieve higher operational performance, reducing downtime associated with mechanical failures and improving overall process efficiency. The ability to fine-tune motor speeds ensures that equipment operates within optimal parameters, ultimately leading to enhanced output and reduced operational costs.

FAQS

: The articles focus on practical advice and knowledge in specific areas of interest.

Regular practice is key. Set achievable goals and track your progress over time.

It’s important to reflect on the situation. Identify what worked and what didn’t.

There are various tools available. Choose ones that match your learning style.

Yes, struggle is part of the learning process. Embrace it as a necessary step.

Find a community for support. Share your goals and celebrate small wins together.

Constructive feedback is essential. It helps you see areas for improvement.

Yes, journaling can provide insights. It helps you reflect on your methods and outcomes.

Accepting failure is crucial. Analyze what went wrong and adjust your approach.

Take breaks when needed. Break tasks into smaller pieces to manage them better.

Conclusion

When selecting the best VFD drive manufacturers, it's essential to understand the basics and applications of VFD drives in various industries. Key factors include evaluating the manufacturer's reputation and experience, as well as analyzing the technical specifications of their drives. It's crucial to consider after-sales support and warranty options, as these can significantly impact your long-term satisfaction and operational efficiency.

Additionally, striking a balance between cost and quality is vital when making your choice, ensuring that you stay within budget while still obtaining reliable products. Finally, checking for industry certifications and compliance standards will help safeguard your investment and ensure that the VFD drives meet necessary safety and performance requirements. By systematically addressing these elements, you can make an informed decision that aligns with your operational needs.

Related Posts

-

Top Strategies for Optimizing Vfd 5.5kw Performance in Your Operations

-

How to Choose the Best VFD Drive Manufacturers for Your Business Needs

-

Why Choosing the Right VFD Suppliers is Crucial for Your Industrial Needs

-

Top 10 Tips for Choosing the Right Vfd Drive Manufacturers for Your Needs

-

Top 10 Vfd Drive Manufacturers You Should Know About?

-

Top 10 VFD Drive Manufacturers from China at the 137th Canton Fair