Maximizing Efficiency: Essential Tactics for 1 Hp Vfd Applications in Modern Industry

Table of Contents

- Understanding the Basics of 1 Hp VFD: Key Features and Applications

- Benefits of Using 1 Hp VFDs in Modern Industry: Cost and Energy Efficiency

- Top Strategies for Implementing VFD in Manufacturing Processes

- Common Challenges Faced with 1 Hp VFD Integration and Their Solutions

- Optimizing Performance: Maintenance Tips for 1 Hp VFD Systems

- Future Trends: The Role of VFDs in Automation and Smart Manufacturing

- Maximizing Industrial Efficiency: Insights from Industry Reports on VFDs and the Role of 55kW 380V Inverters in Performance Optimization

- FAQS

- Related Posts

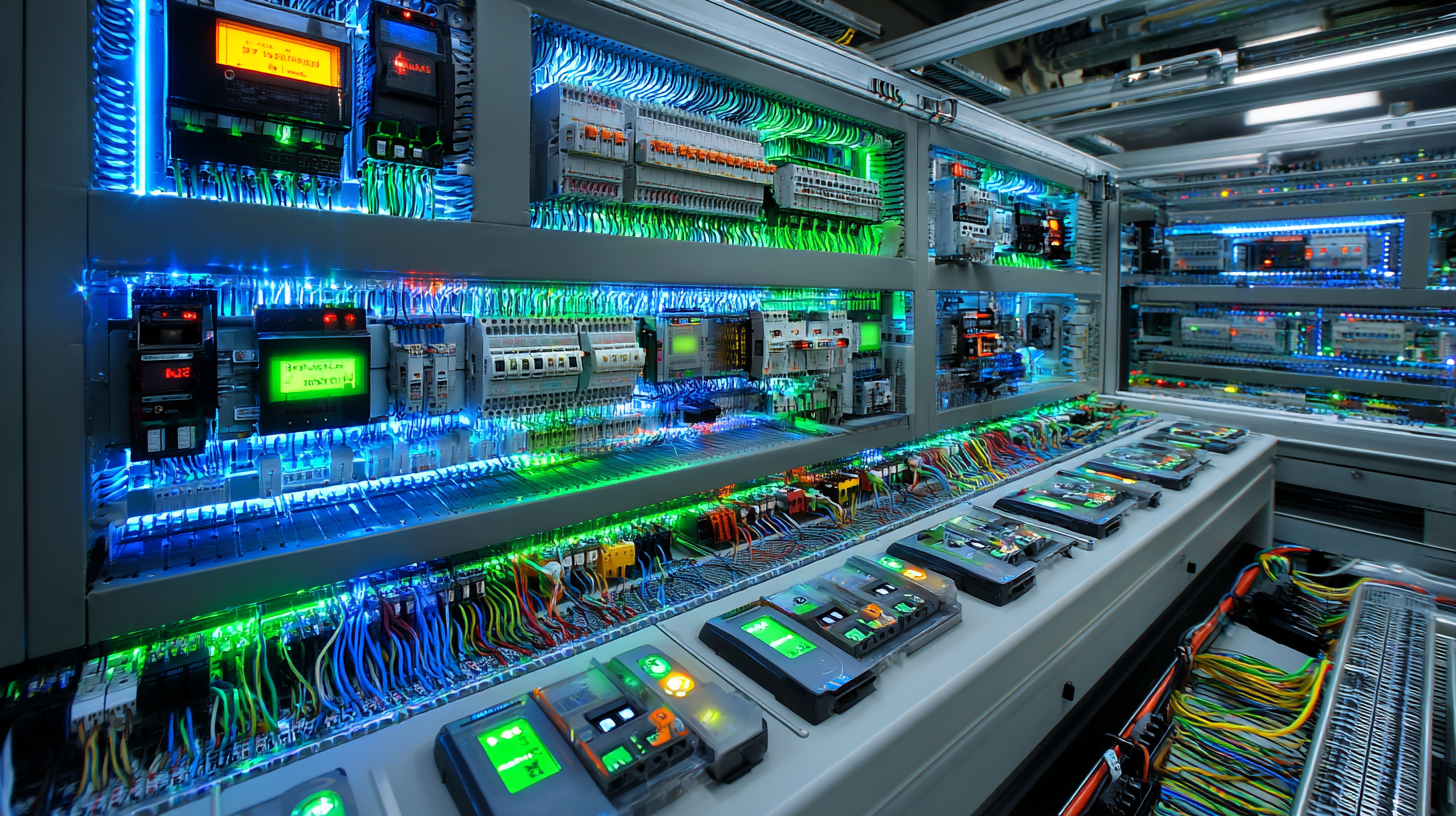

In today's fast-changing industrial world, using really smart automation tech is pretty much essential if you want to keep things running smoothly and efficiently. I recently read a report from the International Electrotechnical Commission, and it showed that Variable Frequency Drives, or VFDs, make up about a quarter to nearly a third of total energy used in factories. That’s a pretty big deal when it comes to saving energy. Specifically, the 1 Hp VFD is a key player—helping small to medium setups run more precisely and cut down on energy wastage at the same time. At Zhejiang Chuanken Electric Co., Ltd., we’ve been in the game of industrial automation for 15 years, and we truly see how powerful a good 1 Hp VFD can be. By combining innovation with our expertise, we're all about helping industries boost their efficiency and cut costs. Honestly, the right technology can really make a difference—that's what we're here to do, support the drive toward better performance and sustainability.

Understanding the Basics of 1 Hp VFD: Key Features and Applications

In today’s industrial world, using 1 Hp Variable Frequency Drives (VFDs) has really become a game-changer. They’re key for improving how smoothly everything runs and for saving energy. A 1 Hp VFD helps control the motor’s speed and torque, which not only keeps things running nicely but also cuts down on power bills. Some industry reports even suggest that adopting VFDs can cut energy use by up to half—pretty impressive, especially for small manufacturing setups.

Getting to know the main features of these 1 Hp VFDs is super important if you want to get the most out of them. They let you fine-tune motor control, making acceleration and deceleration much smoother, which, in turn, helps your equipment last longer. Plus, when you connect VFDs with modern automation systems, everything becomes more reliable and efficient.

These days, a lot of folks are talking about the need for trustworthy automation and control systems at industrial sites. It’s all about having a solid safety setup that includes three main layers—top-tier controls, data protection, and safety strategies. Having this layered approach doesn’t just keep everything secure; it also makes the VFDs work better within a safe, streamlined industrial environment.

Benefits of Using 1 Hp VFDs in Modern Industry: Cost and Energy Efficiency

Switching over to 1 Hp Variable Frequency Drives (VFDs) in today’s industry really offers some pretty big perks, especially when it comes to saving money and energy. I read a study by the U.S. Department of Energy that says using VFDs can cut down energy use by anywhere from 20% up to 50%, depending on what you're applying them to. That’s a pretty huge deal because it can really add up, especially for industries that depend heavily on electric motors—for pumping, HVAC systems, conveyor belts, and the like.

But it’s not just about saving energy. Adding VFDs also helps your equipment last longer. Since they give you fine-tuned control over motor speed and torque, they lessen the amount of stress and wear on your machinery. The DOE’s Motor Systems Analytical Tool even suggests that you could see maintenance costs drop by as much as 30%. That means less downtime and hassle. Plus, with all the buzz around being eco-friendly these days, the fact that VFDs help lower energy consumption lines up perfectly with sustainability goals. All in all, they’re quickly becoming a key piece in today’s industrial setups.

Top Strategies for Implementing VFD in Manufacturing Processes

Nowadays, in modern manufacturing, using Variable Frequency Drives (VFDs) has really been a game-changer when it comes to optimizing how things run. One of the key things to get right is choosing the right size and type of VFD for each specific situation. It’s super important to understand what each application needs — like how the load behaves and what kind of operation you're dealing with. For example, a 1 Hp VFD can make a big difference in saving energy if it’s properly matched with the motor and the task at hand. Getting this right not only boosts performance but also cuts down on wasted energy, which totally helps with the bottom line.

Another thing that really makes a difference is using the advanced control features that modern VFDs come with. Features like torque control and closed-loop feedback systems give manufacturers better control over their machines and processes. This usually means better product quality and faster cycle times. Plus, making sure staff are trained on these sophisticated features is crucial — it helps operators get the most out of their equipment and encourages a culture of ongoing improvement and operational excellence within the plant.

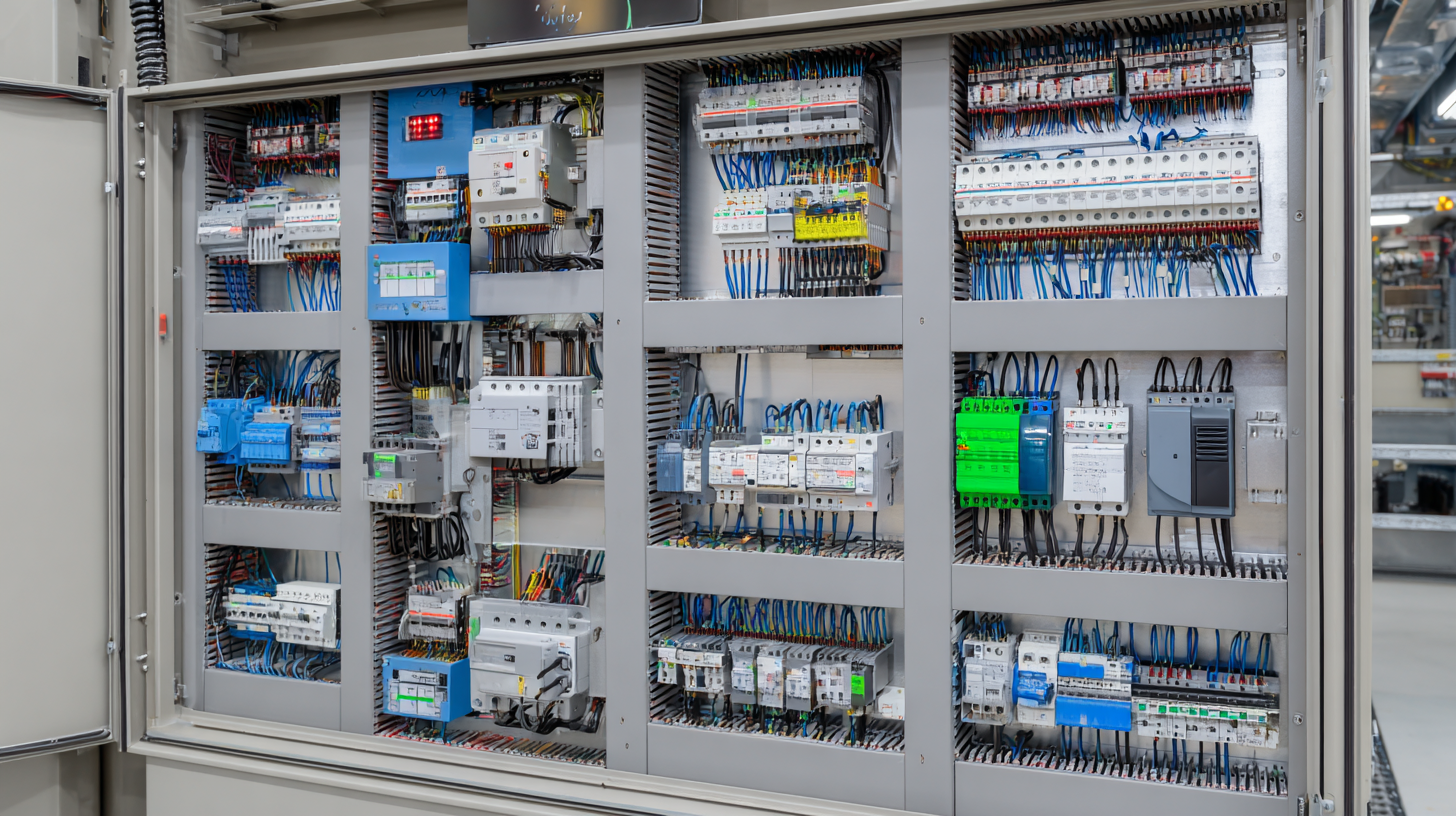

Common Challenges Faced with 1 Hp VFD Integration and Their Solutions

Bringing a 1 HP Variable Frequency Drive (VFD) into today’s industrial setups can really boost how smoothly things run. But, let’s be honest, there are often little hiccups along the way. A big one is making sure the VFD is a good fit for the motor and the specific job it needs to do. Sometimes, people set things up wrong—like misjudging the load—which can lead to poor performance or even damage to the equipment. So, it’s super important to do your homework first—review the motor specs and analyze the load carefully before you go installing anything.

Another common headache? Electromagnetic interference (EMI). VFDs can generate some noise that messes with nearby electronics. Not only does this cause issues with sensitive devices, but it could even create safety risks. To keep things running smoothly, installing filters like line reactors or EMI filters can really help block out that unwanted interference. And don’t forget about grounding—keeping everything properly grounded can make a big difference in reducing electrical noise and improving overall reliability. All in all, with some proper planning and a few compromises here and there, you can make VFD integration much smoother and safer.

Maximizing Efficiency: Essential Tactics for 1 Hp Vfd Applications in Modern Industry

| Tactic | Description | Common Challenges | Solutions |

|---|---|---|---|

| Proper Sizing | Selecting the right VFD for specific load demands to avoid over-sizing or under-sizing. | Performance issues, inefficient operation. | Conduct a detailed load analysis prior to selection. |

| Installation Best Practices | Follow standard installation guidelines to ensure proper functionality and safety. | Incorrect configurations leading to operational issues. | Training for engineers and technicians on VFD installation. |

| Regular Maintenance | Scheduled checks and maintenance activities to prolong VFD lifespan. | Unexpected downtime and repair costs. | Implement a maintenance schedule and adhere to it. |

| Harmonic Mitigation | Reduce harmonic distortion to improve overall system performance. | Potential overheating and equipment failure. | Utilize harmonic filters or proper circuit design. |

| User Training | Ensure operators and maintenance personnel are knowledgeable about VFDs. | Inefficiencies and safety risks due to operator error. | Develop comprehensive training programs and materials. |

Optimizing Performance: Maintenance Tips for 1 Hp VFD Systems

When it comes to taking care of 1 Hp Variable Frequency Drive (VFD) systems, understanding how performance optimization and regular maintenance go hand in hand is a big deal—especially in today’s industrial world. You know, reports have shown that if you keep these VFDs well-maintained, you can boost energy efficiency by up to 30%. That really shows why doing routine checks and calibration is so important. Not only does regular upkeep help these systems last longer, but it also keeps them running smoothly at their best. That means less downtime and fewer unexpected costs, which is a win-win.

One crucial bit of maintenance is keeping an eye on the cooling systems. Overheating can tank the system's efficiency or even cause it to fail entirely. Industry folks suggest that operators should make a habit of cleaning dust off the cooling fans and ensuring good airflow around the VFDs. Plus, with the latest analytics tools, you get real-time data on how the system’s performing. This can help predict issues before they happen—kind of a proactive way to keep things running smoothly. In fact, reports say that predictive maintenance can cut down maintenance costs by about 25% and boost equipment availability by roughly 15%. That’s pretty impressive in terms of getting the most out of your systems.

And it’s not just about VFDs—other industries, like tunnel-style vehicle washes, are also feeling the pressure to get smarter about how they run things. Using water and chemicals efficiently can really make a difference. Same principles apply here—by fine-tuning how systems like VFDs are maintained and optimized, you can see big improvements in efficiency and productivity overall.

Maximizing Efficiency: 1 Hp VFD Applications Performance Analysis

This chart illustrates the performance metrics of 1 Hp Variable Frequency Drive (VFD) applications in modern industrial settings. The parameters include Speed (RPM), Torque (Nm), Efficiency (%), and Heat Generation (°C), providing insights into optimizing performance and maintenance strategies.

Future Trends: The Role of VFDs in Automation and Smart Manufacturing

These days, as industries lean more into automation and smart manufacturing, Variable Frequency Drives (or VFDs for short) are really becoming key players in boosting how efficiently things run. I saw a report from Technavio that says the global VFD market is expected to jump by over 20% between 2022 and 2026 — mostly because everyone's looking for more energy-efficient options. You know, especially with 1 Hp VFDs popping up in all sorts of sectors like HVAC and food processing, where having precise control over motor speed and torque is a must-have.

On top of that, integrating VFDs with IoT tech is opening up some seriously cool possibilities, like better data analysis and predictive maintenance. MarketsandMarkets even predicts that the smart manufacturing market could hit around $650 billion by 2025, and VFDs are a big part of that whole scene. The combo of VFDs and smart tech not only allows for real-time monitoring but also helps streamline production, cut down downtime, and make better use of resources. As companies keep pushing into automation, it’s pretty clear that 1 Hp VFDs are only going to become more essential in today’s industrial world.

Maximizing Industrial Efficiency: Insights from Industry Reports on VFDs and the Role of 55kW 380V Inverters in Performance Optimization

In the quest to maximize industrial efficiency, Variable Frequency Drives (VFDs) play a pivotal role, particularly when paired with high-performance inverters like the 55kW 380V models. These systems are essential for regulating motor speed and torque, significantly enhancing productivity across various applications. Insights from recent industry reports indicate that the implementation of VFDs not only reduces energy consumption but also optimizes the operational performance of machinery, leading to longer equipment lifespans and reduced maintenance costs.

One standout option in this market is the SHCKELE SCK300 inverter. Designed for general use, the SCK300 model is engineered to handle the demands of diverse industrial environments. With an impressive warranty of 18 months, it ensures reliability and peace of mind for operations that rely on sustained performance. By leveraging advanced technology, the SCK300 inverter enhances energy efficiency, giving plants the competitive edge needed to thrive in today's fast-paced manufacturing landscape. Implementing such high-quality inverters is integral to unlocking the full potential of industrial processes and achieving substantial operational gains.

FAQS

: A Variable Frequency Drive (VFD) is a device that controls the speed and torque of electric motors by varying the frequency and voltage of the power supplied to the motor. Its significance lies in optimizing operations, enhancing energy efficiency, and improving performance in manufacturing processes.

Effective sizing and selection of a VFD require understanding the specific requirements of each application, including load characteristics and operational demands. Proper matching of the VFD, such as a 1 Hp VFD, with the motor can significantly enhance energy efficiency and performance.

Modern VFDs offer advanced control algorithms, such as torque control and closed-loop feedback systems, which allow for more precise control over machinery and processes, leading to improved product quality and reduced cycle times.

Regular maintenance of 1 Hp VFD systems is crucial as it can improve energy efficiency by up to 30%, prolong the lifespan of systems, ensure peak performance, and reduce operational costs by minimizing downtime.

Key maintenance strategies include monitoring cooling systems to prevent overheating, regularly cleaning dust from cooling fans, ensuring proper airflow, and utilizing advanced analytics tools for real-time insights and predictive maintenance.

Predictive maintenance can reduce maintenance costs by 25% and increase equipment availability by 15%, enhancing operational efficiency by allowing for timely interventions before issues escalate.

The integration of VFDs with IoT technologies is paving the way for advanced data analytics and predictive maintenance, contributing to the growth of the smart manufacturing market, projected to reach $650 billion by 2025.

1 Hp VFD applications are gaining traction in sectors such as HVAC and food processing, where precise control of motor speed and torque is crucial for operational efficiency.

VFDs contribute to energy efficiency by optimizing motor control according to specific application needs, reducing energy waste, and improving overall operational performance.

VFDs are vital components in enhancing operational efficiency in automation, facilitating real-time monitoring, optimized production processes, and better resource utilization within industrial systems.

Related Posts

-

The Ultimate Checklist for Sourcing the Best Vfd Abb for Your Industrial Needs

-

How to Choose the Best 45kW VFD for Your Industrial Applications

-

Emerging Vfd Inverter Technologies in 2025 Exploring Alternatives to 1.5kw Solutions

-

Understanding Industry Standards for Best Soft Starter Cabinet Selection Guide

-

Understanding Import and Export Certifications for the Best Vfd Control Board in Global Markets

-

Elevating Global Standards with Best 250 Kw Vfd Drive From China