What is Mini Vfd and How It Revolutionizes Energy Efficiency in Industrial Applications

Table of Contents

- Understanding Mini VFD: A Compact Solution for Energy Savings

- Key Features of Mini VFD: Why It's Essential for Industrial Efficiency

- How Mini VFDs Improve Motor Control in Industrial Settings

- Comparative Energy Savings: Mini VFD vs Traditional Drives

- Real-World Applications of Mini VFDs in Various Industries

- Future Trends: The Evolving Role of Mini VFDs in Energy Management

- Unlocking Efficiency: The Benefits of Using a 55kW 3-Phase VFD Motor Speed Controller

- FAQS

- Conclusion

- Related Posts

You know, the arrival of Mini VFD (Variable Frequency Drive) technology really marks a big shift when it comes to energy efficiency in industrial setups. With energy costs climbing and the push for more sustainability, Mini VFDs are becoming pretty much essential. They offer better control and can save a ton of energy at the same time. I recently read a report from the International Energy Agency that said using variable speed drives can cut energy use in electric motor systems by up to 60%. That’s a huge deal!

You know, the arrival of Mini VFD (Variable Frequency Drive) technology really marks a big shift when it comes to energy efficiency in industrial setups. With energy costs climbing and the push for more sustainability, Mini VFDs are becoming pretty much essential. They offer better control and can save a ton of energy at the same time. I recently read a report from the International Energy Agency that said using variable speed drives can cut energy use in electric motor systems by up to 60%. That’s a huge deal!

Zhejiang Chuanken Electric Co., Ltd., which has been around for 15 years and specializes in industrial automation control products, totally gets how important Mini VFDs are for modern operations. By bringing in this tech, companies can not only use energy more wisely but also lower their carbon footprint—pretty much hitting two birds with one stone and aligning with global environmental goals.

In this blog, I’ll dive into how Mini VFDs are really changing the game when it comes to energy efficiency in the industry.

Understanding Mini VFD: A Compact Solution for Energy Savings

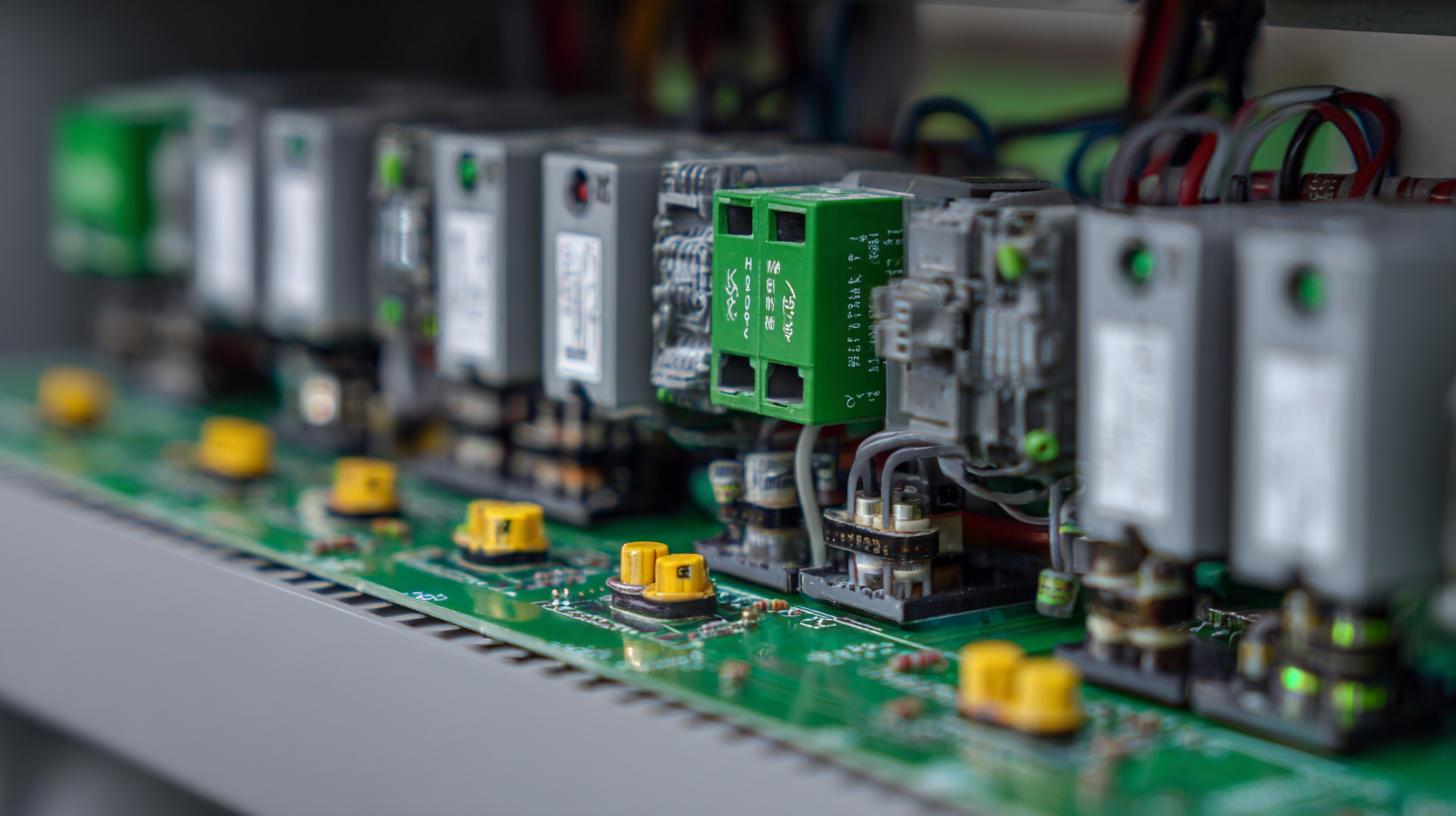

Mini VFDs, or Variable Frequency Drives, have really become a game-changer in industrial settings, especially when it comes to air handling units (AHUs). These tiny devices can do a lot to boost energy efficiency because they let you fine-tune the motor speed and torque precisely—meaning you use less electricity and cut down on costs. Their compact size is a big plus, too, making it super easy to upgrade existing systems without tearing everything apart and starting from scratch.

Quick tip: When you're thinking about installing Mini VFDs, take a moment to really understand what your equipment needs. Knowing how much load it's handling and the range of speeds you might use can help you get the most out of these drives—and save even more energy in the process.

As more industries focus on going green, Mini VFDs are playing an important role in reducing carbon footprints. They integrate smoothly with energy management systems, helping not just to streamline operations but also to gather essential data on performance. This info makes it easier for companies to make smarter decisions about their energy use.

Another tip: Keeping up with regular maintenance on your VFDs is key to keeping them working their best. Simple routine checks—like cleaning the parts and double-checking the settings—can make a big difference in ensuring you get the maximum benefit and long-lasting reliability from these drives.

Key Features of Mini VFD: Why It's Essential for Industrial Efficiency

Mini VFDs, or Variable Frequency Drives, are honestly a game-changer when it comes to boosting energy efficiency in a bunch of industrial setups. These little guys are compact, but don’t let their size fool you—they pack a punch with advanced control features and the ability to make processes run smoother and more efficiently. Basically, they help save a ton of energy by allowing you to fine-tune motor speed and torque, which means everything operates more perfectly. If you're in the manufacturing world and want to cut costs while being kinder to the environment, Mini VFDs are really worth considering.

Mini VFDs, or Variable Frequency Drives, are honestly a game-changer when it comes to boosting energy efficiency in a bunch of industrial setups. These little guys are compact, but don’t let their size fool you—they pack a punch with advanced control features and the ability to make processes run smoother and more efficiently. Basically, they help save a ton of energy by allowing you to fine-tune motor speed and torque, which means everything operates more perfectly. If you're in the manufacturing world and want to cut costs while being kinder to the environment, Mini VFDs are really worth considering.

Here are some handy tips for getting started with Mini VFDs:

- Check Compatibility: Before you dive in, make sure your current machinery and systems can actually handle these drives. It’ll save you from surprises later and keep costs down on upgrades.

- Get Your Team Trained: It’s super important that your team knows how to operate and maintain these drives properly. A little training goes a long way in helping folks troubleshoot issues and set everything up for max energy savings.

- Keep an Eye on Performance: Use data and analytics to keep tabs on how your Mini VFDs are doing. Regular checks can uncover ways to improve and help avoid unnecessary downtime.

All in all, adding Mini VFDs isn’t just about saving energy — it’s also about stepping up your game in making manufacturing more sustainable. Plus, it’s pretty rewarding to know you're doing your part for the environment.

How Mini VFDs Improve Motor Control in Industrial Settings

Mini Variable Frequency Drives, or VFDs for short, are really changing the game when it comes to controlling motors in industrial settings. They’re small but mighty, allowing for much精准 control of motor speed and torque, so everything runs just right based on whatever’s needed at the moment. As more industries get serious about sustainability, it’s no surprise that more companies are jumping on the Mini VFD bandwagon. For example, utility air screw compressors are now experimenting with VFD tech to cut down on energy use significantly. In fact, recent stats show that the global market for variable frequency drives is expected to grow from about $24.7 billion in 2025 to around $32 billion, highlighting a clear move toward more energy-efficient solutions.

Adding a Mini VFD can also seriously cut down operational costs. Just think about how installing VFDs on pumps and fans gives you better control over speed and processes—that means you’re using energy more efficiently and saving cash. A couple of tips if you want to get the most out of your Mini VFD? Make sure it’s the right size for your specific application, and don’t forget regular maintenance to keep everything running smoothly.

Plus, it’s worth mentioning how well VFDs work when paired with modern motor tech, like IE4-rated motors that come with built-in variable frequency drives. That combo not only boosts overall performance but also helps cut energy bills and makes your operations more reliable. Bottom line? Investing in Mini VFD technology is a smart move—it saves energy, saves money, and supports greener practices all at once.

Comparative Energy Savings: Mini VFD vs Traditional Drives

You know, the arrival of Mini Variable Frequency Drives (VFDs) really marks a pretty big milestone when it comes to boosting energy efficiency in industrial settings. Unlike the old-school drives that run at a fixed speed—which can waste a ton of energy—these little guys are quite the game changer. They're designed to be more flexible, adjusting the motor’s speed and torque on the fly to match what's actually needed. And honestly, that translates to some serious savings on energy bills.

Lately, the market for VFDs has been booming. Experts are predicting it’ll hit around $32 billion by 2025, which just shows how much companies are leaning towards greener, more efficient solutions. There’s also been some cool new methods developed to figure out how much energy is actually wasted in this space. People are calling for a standard way to rate how energy-efficient different pieces of industrial equipment are—kind of like a global scorecard. All in all, Mini VFDs are looking pretty promising in this competitive scene, especially considering how much energy they can save compared to those old drive systems. It’s exciting to see how this tech is shaping the future of industry and sustainability!

Comparative Energy Savings: Mini VFD vs Traditional Drives

Real-World Applications of Mini VFDs in Various Industries

Mini Variable Frequency Drives, or VFDs for short, are really starting to catch on across a bunch of different industries. People love how they boost energy efficiency and are small enough to scale easily. Basically, these tiny devices are used to control how fast and how much torque electric motors deliver. They're actually changing the game in sectors like manufacturing, HVAC, and even renewable energy. Industry experts are saying that by using Mini VFDs, companies could see energy savings of up to 30% on things like pumps and fans — which means lower operating costs and a smaller carbon footprint. Pretty impressive, right?

In manufacturing, you often see Mini VFDs being hooked up to conveyor belts and automated machines to make everything run smoother and cut down on electricity use. For example, in textiles, having that precise motor control really boosts production efficiency. And when it comes to HVAC systems, these drives help fine-tune fan speeds, which not only improves air quality but also slashes energy consumption. As the market for these little guys keeps growing — projections are hitting around $190 billion by 2023 — businesses are eager to jump on board and use these techs to get more efficient and greener at the same time.

Future Trends: The Evolving Role of Mini VFDs in Energy Management

Lately, the way Mini Variable Frequency Drives (or VFDs) are playing a role in energy management is really changing how industries think about saving energy. The global market for VFDs is expected to grow a lot, especially with things like IoT and the rise of smart cities pushing things forward. Mini VFDs are quickly becoming a key part of energy solutions because they’re so compact — perfect for fitting into tight spaces in modern factories and plants. They help optimize equipment and machinery while cutting down on energy use, which is pretty cool.

More companies are looking to adopt greener practices, and the flexibility of Mini VFDs in hybrid power setups is definitely worth noting. They give you better control over motors and other gear, and they can really make a difference in energy savings — think electric propulsion in smart ships or electrifying industrial hydraulics. Basically, these tiny drives are changing the game in how we monitor and use energy. They’re leading the charge toward more efficient and environmentally friendly operations, helping us cut down on carbon footprints across all sorts of sectors.

Unlocking Efficiency: The Benefits of Using a 55kW 3-Phase VFD Motor Speed Controller

The advent of Variable Frequency Drives (VFD) has revolutionized the way we manage motor speed and energy consumption. With products like the SHCKELE SCK300, a 55kW 3-Phase VFD Motor Speed Controller, industries can realize significant efficiency gains. According to a report by the U.S. Department of Energy, the use of VFDs can lead to energy savings of 20-50% in motor-driven systems, making it a critical investment for businesses looking to reduce operational costs.

The SCK300 VFD is designed for general applications and comes with an 18-month warranty, providing users with peace of mind as they unlock the benefits of enhanced control over motor performance. By precisely regulating motor speed, companies can optimize processes, reduce wear and tear on equipment, and enhance product quality. Studies indicate that employing VFD technology not only contributes to lower energy bills but also aids in decreasing greenhouse gas emissions, aligning with sustainability goals in manufacturing and industrial operations.

Moreover, this 3-Phase VFD motor speed controller facilitates easier integration into existing systems, making it a versatile option for various industrial applications. Businesses that have adopted VFD technology have reported improved operational flexibility, further enabling them to respond swiftly to changes in production demands. In an era where efficiency is vital, the SCK300 stands out as a robust solution for those striving to enhance their operational capabilities while promoting energy conservation.

FAQS

: Mini Variable Frequency Drives (VFDs) are compact devices that enhance energy efficiency in industrial applications by enabling precise control of motor speed and torque, ultimately optimizing operational processes and promoting energy savings.

Industries should assess their existing machinery and systems to ensure compatibility with Mini VFDs. This process helps maximize efficiency and reduce retrofitting costs.

Proper training on the operation and maintenance of Mini VFDs is essential. Teams should be empowered with the knowledge to troubleshoot and optimize settings for greater energy savings.

Regular performance monitoring using data analytics can identify patterns and areas for improvement, leading to enhanced efficiency and reduced downtime for systems utilizing Mini VFDs.

Mini VFDs can significantly reduce operational expenses by optimizing energy usage in various machines, such as pumps and fans, through better process and speed control.

Mini VFDs seamlessly integrate with modern motor technologies, such as IE4-rated motors, which feature built-in variable frequency drives, enhancing performance and reducing energy costs.

The integration of Mini VFDs with IoT and their use in hybrid power systems are key trends, as they allow for better control over motors and significant energy savings in various applications.

Mini VFDs are especially effective in applications like electric propulsion in smart ships and the electrification of industrial hydraulics, contributing to energy management and sustainability efforts.

The expected growth of the global variable frequency drive market highlights an industry shift towards energy-efficient solutions, illustrating the increasing demand for technologies that improve energy management.

By enabling significant energy savings and optimizing motor control, Mini VFDs support sustainable manufacturing practices, helping industries reduce their environmental impact.

Conclusion

You know, in the world of industrial automation, the Mini VFD (Variable Frequency Drive) is really making waves as a game-changer. It’s small, but don’t let that fool you—these tiny devices pack a punch when it comes to saving energy and giving you better control over motors. Honestly, compared to the older, bulkier drives, mini VFDs can really help cut down on energy costs, which is a big win for pretty much any industrial setting these days. Plus, they help fine-tune motor performance, making operations smoother, cheaper, and more eco-friendly overall.

At Zhejiang Chuanken Electric Co., Ltd., we’ve been in the game for over 15 years, specializing in automation control products. We see firsthand just how powerful Mini VFD technology is becoming. As industries seriously start to shift towards smarter, more sustainable solutions, this little device is set to be at the heart of energy management efforts. It’s all about helping companies hit their efficiency and sustainability targets while still keeping things running great on the operational side. Exciting times, right?

Related Posts

-

Unlocking Efficiency: A Comprehensive Tutorial on Selecting the Best 0.75kw VFD for Your Industrial Needs

-

10 Best 50hz 60hz Soft Starters for Efficient Motor Control

-

The Ultimate Guide to Selecting the Best Vfd Controller for Your Industrial Needs

-

Leading VFD Pump Controller Manufacturers from China at the 137th Canton Fair

-

Navigating Tariffs: Why the 200kW Best VFD Inverter from China Is Your Best Import Choice

-

Unlocking Efficiency with the Benefits of the Best Pressure Booster Vfd Technology