How to Optimize Your Operations with Vfd Manual Best Practices for Increased Efficiency

Table of Contents

- Understanding VFDs: The Basics and Benefits for Operational Efficiency

- Key Best Practices for Implementing VFDs in Your Operations

- Common Challenges in VFD Use and How to Overcome Them

- Monitoring and Maintenance Strategies for Optimal VFD Performance

- Case Studies: Successful VFD Implementations and Lessons Learned

- FAQS

- Conclusion

- Related Posts

In today’s fast-changing industrial world, really optimizing how things run is more important than ever if you want to boost efficiency and cut costs. Just recently, the International Society of Automation shared a report – and it’s pretty eye-opening – companies that put Variable Frequency Drive (VFD) technology into action can slash energy use by up to half! That’s a huge deal for their bottom line.

Over here at Zhejiang Chuanken Electric, we’ve been in the game for 15 years, focusing on developing and making industrial automation control products. We totally get how vital a solid VFD Manual is for unlocking those savings. When companies follow the best practices outlined in the manual, they can get the most out of their automation systems, make their processes smoother, and grow sustainably.

This guide’s all about sharing key tips on how to use the VFD Manual effectively to really boost productivity and efficiency—so, let’s dive in!

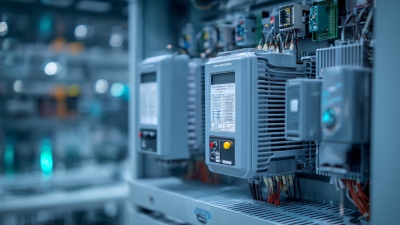

Understanding VFDs: The Basics and Benefits for Operational Efficiency

Variable Frequency Drives, or VFDs for short, are pretty much game-changers in today’s industrial world. They let you control motor speed and torque, which honestly, can really boost efficiency. If you get a good grip on how VFDs work, it can make a big difference—cutting down energy bills and helping your equipment last longer. When you adjust the motor speed to match what’s needed at the moment, things run more smoothly, and your machinery doesn't wear out as fast. That means you end up saving money in the long run.

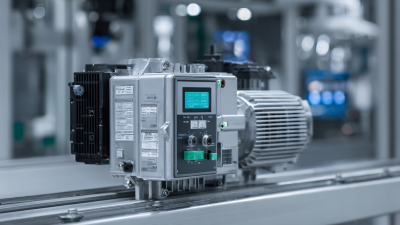

Tip 1: To get the most out of your VFDs, pay close attention during installation and setup. Make sure it’s compatible with your motor and that you tweak the settings just right for your specific needs. Taking the time to calibrate things properly really pays off—performance improves, and so does your energy savings.

Tip 2: Regular check-ups are key to keeping your VFD in good shape. Keep an eye on the connections, watch out for overheating, and periodically assess how it's performing. Setting up a routine maintenance schedule can help catch issues early before they turn into bigger problems, so your operations keep running smoothly without unexpected hiccups.

Basically, understanding the ins and outs of VFDs and sticking to these best practices can seriously boost your operational efficiency—and save you some bucks along the way.

Key Best Practices for Implementing VFDs in Your Operations

Adding Variable Frequency Drives (VFDs) to your setup can really give your operations a boost — but only if you follow some important best practices. First off, it’s crucial to really understand what your system needs. Knowing the specifics of your application helps you pick the right VFD, ones that match your operational demands. That way, you get better performance and save energy at the same time.

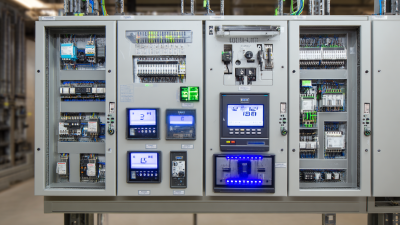

Another thing to keep in mind is training your team properly. Giving folks good training means they’ll know how to run and maintain the VFDs without messing things up, which helps avoid unnecessary downtime. Regular maintenance is also key — it stops surprises and keeps your equipment running longer, saving you money and headaches. Lastly, don’t forget about data analytics tools. They can give you useful insights into how everything’s performing, so you can make tweaks and improvements on the fly.

By sticking to these simple but effective best practices, your organization can really unlock the full potential of VFDs, leading to smoother operations and better overall efficiency.

Efficiency Improvement with VFDs

Common Challenges in VFD Use and How to Overcome Them

Variable Frequency Drives, or VFDs for short, have really become a staple in today’s industrial setups. But, honestly, they’re not without their quirks. One thing I see quite often is folks not setting them up quite right, which can lead to wasting energy and even putting unnecessary stress on the equipment. The trick? Spend a bit of time really getting to know your machinery’s needs and tweak those VFD settings accordingly. Also, regular training sessions are super helpful—they keep everyone in the loop on the best ways to handle VFDs, which ends up boosting overall efficiency.

Another headache that pops up is heat buildup, especially if the VFDs are in stuffy spots with poor ventilation. Over time, this can cause overheating or, worse, equipment failure. To avoid that, it’s a solid idea for facilities to invest in proper cooling systems and make sure the VFDs are placed somewhere with good airflow. And don’t forget about routine maintenance on those cooling systems—staying on top of it means catching potential problems early and keeping everything running smoothly for the long haul. By tackling these issues head-on, businesses can really make the most of what VFDs have to offer and keep operations running efficiently.

Monitoring and Maintenance Strategies for Optimal VFD Performance

Keeping an eye on and properly maintaining your Variable Frequency Drives (VFDs) is honestly pretty crucial if you want them to work their best. Starting with regular monitoring can really help spot weird patterns or potential issues before they turn into big headaches. Think of it like giving your VFD a health check—tracking things like voltage, current, and temperature, and occasionally inspecting parts like capacitors or cooling systems. Using modern monitoring tools or software makes this a lot easier, giving you real-time data so you can tweak things quickly or jump in before problems get out of hand.

And don’t forget, routine maintenance is just as important. Setting up a solid schedule for cleaning, lubricating, and testing can save you a lot of hassle down the line by reducing downtime and making your equipment last longer. Pay close attention to connections—look for corrosion and make sure everything's tightly secured. Updating the software and firmware regularly is another key step because it helps you take advantage of new features and fixes, ensuring your VFD runs smoothly at peak performance. Overall, nailing these monitoring and maintenance routines can seriously boost how efficiently and reliably your VFD operates, no kidding.

Case Studies: Successful VFD Implementations and Lessons Learned

Using Variable Frequency Drives (VFDs) has really proven to boost efficiency across a bunch of different industries. I recently came across a report from the U.S. Department of Energy that said VFDs can cut down energy use in motor-driven systems by anywhere from 20% to 50%. Pretty impressive, right? For instance, there was this manufacturing plant that upgraded their motor controls to VFDs, and within just six months, they saw their energy costs drop by about 30%. That just goes to show how grabbing onto modern tech can really pay off financially.

If you're thinking about implementing VFDs, it’s a good idea to follow some best practices to get the most out of them. A solid first step is to take a close look at your current systems—spotting areas that could use improvement. It also helps to chat with manufacturers who are experts in VFD tech; they can give you insights tailored to your specific setup. And don’t forget about training your team! Regular maintenance and operation training ensures everyone’s on the same page, which can extend the lifespan of the equipment and keep things running smoothly. Plus, your staff will be better equipped to handle any issues that might pop up.

Here’s another example: an HVAC company that added VFDs into their systems managed to cut power usage by about 25%. That not only saved them money but also boosted their system reliability. It really shows how different sectors—whether manufacturing or HVAC—can benefit from VFDs, not just in terms of saving energy but also making their operations way more efficient. Doing case studies like these can really help uncover best practices, setting the stage for effective VFD use across all kinds of industries.

FAQS

: VFDs are used to control motor speed and torque, enhancing operational efficiency by reducing energy consumption and improving equipment lifespan.

Proper installation and configuration ensure that the VFD is compatible with the motor and optimized for operational needs, leading to improved performance and energy efficiency.

Regular maintenance should include checking connections, monitoring for overheating, and assessing performance periodically to identify potential issues before they escalate.

Assessing system requirements allows for the selection of the appropriate VFD that matches the operational demands, ensuring optimized performance and energy savings.

Comprehensive training programs empower staff to operate and maintain VFDs effectively, minimizing downtime due to operator error and increasing overall efficiency.

Data analytics tools provide valuable insights into operational performance, enabling continuous improvement and timely adjustments to maximize efficiency.

A routine maintenance schedule helps prevent unexpected failures and prolongs the lifespan of the equipment, ensuring efficient and uninterrupted operations.

Yes, by regulating motor speed according to load requirements and reducing wear on machinery, VFDs contribute to cost savings through enhanced operational efficiency.

VFDs enable better control over motor speed, resulting in smoother processes, less wear on machinery, and improved operational efficiency.

A key best practice is to prioritize training for team members to ensure they can operate and maintain VFDs effectively, maximizing the benefits of the technology.

Conclusion

In today’s super competitive industrial world, finding ways to optimize operations with Variable Frequency Drives (VFDs) is pretty much a must if you wanna boost efficiency. Our blog, “How to Optimize Your Operations with VFD Manual Best Practices for Increased Efficiency,” dives into the basics of VFDs, highlighting how they can really improve your operational game. We’ll walk you through some practical tips for implementing VFDs smoothly — because let’s face it, it’s not always straightforward — and give you a few pointers on common hurdles you might run into along the way.

We also stress how important it is to keep an eye on monitoring and maintenance to keep those VFDs performing at their best. To give you a clearer picture, we include some real-world case studies of companies that nailed it with VFDs — sharing what worked and what didn’t. If you follow our VFD manual and these best practices, you should be all set to level up your automation processes and see some serious operational improvements.

Related Posts

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Exploring the Advantages of 10hp Vfd Over Traditional Motor Solutions

-

Exploring Innovative Alternatives to the Best Pump VFD for Enhanced Efficiency

-

Top Strategies for Optimizing Vfd 5.5kw Performance in Your Operations

-

Future Trends in VFD Market Analysis for 5.5kw Drives by 2025 with Essential Tips for Success

-

How to Choose the Best 45kW VFD for Your Industrial Applications