How to Select the Best China Vfd for Your Industrial Needs

Table of Contents

- Understanding the Basics of Variable Frequency Drives (VFDs)

- Key Types of China VFDs and Their Industrial Applications

- Factors to Consider When Choosing a VFD for Your Industry

- Comparing the Leading China VFD Brands: Features and Performance

- Common Misconceptions About China VFDs and Their Reliability

- Best Practices for Implementing VFDs in Your Industrial Setup

- FAQS

- Conclusion

- Related Posts

When it comes to optimizing industrial processes, choosing the right Variable Frequency Drive (VFD) can really make a big difference. In this guide, we’ll walk through how to pick the best VFD made in China for your specific needs. As one of the top players in the field, Zhejiang Chuanken Electric Co., Ltd. is proud to bring over 15 years of experience in researching, developing, manufacturing, and selling industrial automation products. It’s super important to understand what your particular application needs — with so many options out there, making the right choice can boost your efficiency and overall performance.

In this blog, I’ll share some key things to consider, must-have features, and tips for navigating the wide world of Chinese VFDs—so you can find exactly what works best for your operations.

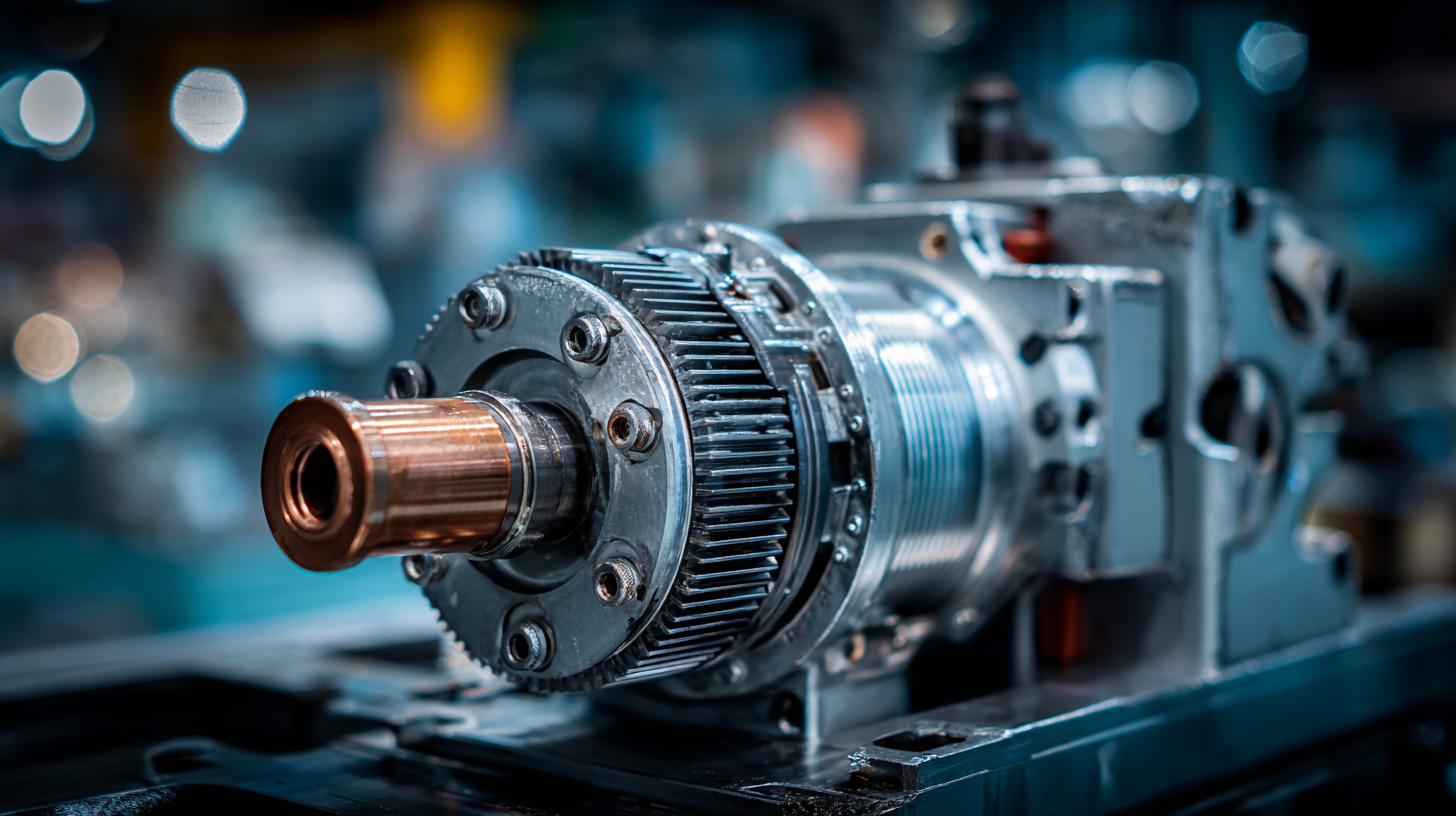

Understanding the Basics of Variable Frequency Drives (VFDs)

When you're trying to pick out the best variable frequency drive (VFD) for industrial uses, it really pays to understand the basic ideas behind how these things work. Basically, a VFD controls the speed and torque of electric motors by tweaking the frequency and voltage going to them. This means you get better control over how stuff runs, it can save energy, and ultimately helps your equipment last longer. Once you get a grip on how VFDs work—especially compared to other ways of controlling motors like old-school starters or inverters—you can make smarter choices that fit your specific needs.

You can’t ignore how popular VFDs are becoming across different industries—they’ve got some clear advantages over the older tech. Plus, there’s been a lot of talk lately, like webinars and online courses, showing just how versatile these drives are, especially in automating processes and working really well with newer AC permanent magnet motors, which are getting more popular due to their efficiency. And with all the online resources and virtual tech talks out there, it’s a lot easier to learn about all the different control methods and modulation techniques used with VFDs. This kind of info not only helps you pick the right drive for your particular setup but also gives techs and engineers the tools to really fine-tune performance in various industrial environments.

Key Types of China VFDs and Their Industrial Applications

When you're on the hunt for the best variable frequency drive (VFD) from China to fit your industrial needs, it’s super helpful to really understand the different types out there and what they’re best suited for. Usually, VFDs fall into a few main categories: voltage source inverters (VSI), current source inverters (CSI), and those with vector control. Each one has its own role—some are perfect for basic motor speed control, while others are designed for more complex stuff like automation or robotics.

A good tip? Think about what exactly your application needs. Things like the types of loads you’re working with and how precise the control has to be—these really matter. Also, don’t forget to consider the environment where the VFD will be working. If your setup involves a lot of starting and stopping or if it’s in a tough, harsh setting, you might want to go for a tougher, more durable drive. Plus, make sure whatever you pick plays nicely with your existing systems and check out its energy efficiency so you can keep costs in check.

One more thing that’s becoming pretty important nowadays—look into VFDs that boast AI and automation features. As industries move toward smarter manufacturing, having a VFD with intelligent capabilities can seriously boost productivity. It allows for real-time monitoring and better, adaptive control. Staying on top of the latest trends in industrial automation is a smart move to make sure your drive is ready for future innovations in your field.

Factors to Consider When Choosing a VFD for Your Industry

When you're on the hunt for the best Variable Frequency Drive (VFD) for your industrial setup, there are a bunch of important things you really should consider to make sure everything runs smoothly and efficiently. First off, think about what your specific application needs—different industries have their own quirks, like different motor sizes, speed control requirements, and working conditions. Funny enough, a report from MarketsandMarkets mentions that the global VFD market is projected to grow at a CAGR of about 6.6% between 2020 and 2025. This just shows how more and more industries are jumping on the bandwagon for energy-efficient tech.

Beyond that, you gotta check if the VFD plays nicely with your existing gear. Making sure it works seamlessly with your motors and automation setups can save you a lot of headaches later on. Also, don’t forget to consider the kind of load you'll be dealing with, whether you need a VFD that handles heavy starting torque or can cope with overloads. For example, if you're working with high-inertia loads, you’ll want a VFD that can provide the high starting torque needed for reliable operation.

Pro tip: Always take a good look at the manufacturer’s specs and documentation. That way, you'll know exactly what features the VFD has and whether it really fits your needs.

Another big thing is the environment where the VFD will be installed. Temperature, humidity, dust, even exposure to corrosive stuff—these can seriously impact how long your VFD lasts and how well it performs. Here at Zhejiang Chuanken Electric Co., Ltd., we’ve been delivering custom industrial automation solutions for over 15 years, so we know a thing or two about making sure our VFDs stand up to tough conditions while exceeding standards.

Quick tip: Pick a VFD with an IP rating suitable for your environment—that’s key to making it last longer and work more reliably.

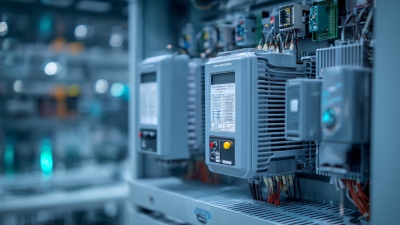

Comparing the Leading China VFD Brands: Features and Performance

Picking out the best variable frequency drive (VFD) for industrial use isn't just about grabbing the biggest brand out there. You really gotta compare the top players in China, look at their features, performance, and how well they actually hold up. The global market for VFDs is booming, expected to hit around $32 billion by 2025, and manufacturers are constantly coming up with new tech to satisfy all sorts of industrial needs. When you're choosing, keep an eye on stuff like energy savings, how easily it can integrate with your existing setup, and the variety of control options it offers.

Now, because this market’s so competitive, not all VFDs are created equal. Some brands might be better at handling different motor types or environmental conditions, while others might shine in reliability or ease of use. A lot of them now come with smart diagnostics and features that can really boost system performance and cut down on downtime. Plus, taking a quick peek at user reviews or industry case studies can give you a better idea of how these drives perform in real-world scenarios. So, really understanding what each brand has to offer — their strengths, weaknesses, and special features — is key to making a choice that'll genuinely fit your specific needs.

Comparison of VFD Features and Performance

Common Misconceptions About China VFDs and Their Reliability

When you're looking into Variable Frequency Drives (VFDs) from China, it's pretty common for folks in the industry to have some misconceptions about their reliability. One of the biggest myths is that Chinese VFDs just don’t match up to those from the West—you know, like they’re somehow inferior. But honestly, that thinking doesn’t really take into account how much Chinese manufacturers have stepped up their game, investing in advanced tech and stricter quality control measures. These days, many Chinese companies run hi-tech factories and do thorough testing, so their products often meet, if not exceed, international standards.

Another thing I hear quite a bit is that Chinese VFDs lack good technical support or after-sales service. Yeah, that used to be somewhat true years ago, but things have changed quite a lot. Now, a lot of reputable Chinese brands offer solid support—think online resources, local distributors, and fast, friendly customer service. It’s pretty clear that their dedication to customer satisfaction has really improved, which should give you more confidence in choosing Chinese VFDs for your projects. So, by clearing up these misconceptions, companies can really make smarter decisions—and maybe even find that Chinese VFDs are a budget-friendly and innovative option worth considering.

Best Practices for Implementing VFDs in Your Industrial Setup

When you're adding Variable Frequency Drives (VFDs) into your industrial setup, it’s really important to follow some best practices to keep everything running smoothly and make sure your equipment lasts longer. First off, take a good, hard look at your current gear and processes. Before you pick out a VFD, it’s smart to analyze what exactly your application needs—think about the kind of motor you're using, how it operates, and what level of control is required. Choosing the right-sized VFD can actually boost energy savings and help reduce wear and tear on your motors, which means fewer repairs and more reliable operation.

Another thing to keep in mind is making sure the VFDs are installed and configured correctly. That means following the manufacturer’s advice on wiring, grounding, and making sure the environment is suitable. Don’t forget to train your team on how to operate and maintain the VFDs properly—knowing the ins and outs can really prevent a lot of common problems. Also, keeping an eye on performance over time can reveal inefficiencies and give you useful data to fine-tune things further.

If you stick to these best practices, your industry can really tap into the full benefits of VFDs—like higher productivity and longer-lasting equipment.

FAQS

: A VFD is a device that regulates the speed and torque of electric motors by adjusting the frequency and voltage supplied to them, enhancing control, energy efficiency, and equipment lifespan.

VFDs provide significant advantages over traditional motor starters and inverters by offering improved control over operational processes and increasing energy efficiency.

VFD technology is gaining popularity due to its versatility in advanced automation and its integration with AC permanent magnet motors, which are recognized for their efficiency.

Best practices include conducting a thorough assessment of existing equipment, ensuring proper installation and configuration, providing staff training, and regularly monitoring performance.

Considerations include motor type, operational requirements, load characteristics, and the specific nature of the control needed for your applications.

A properly sized VFD can enhance energy efficiency, reduce wear on motors, and subsequently lead to cost savings and improved reliability in industrial applications.

Training personnel on VFD operation and maintenance is crucial, as informed staff can prevent common issues arising from misuse and ensure optimal performance.

Regular monitoring can identify potential inefficiencies and provide data for further optimization, thus enhancing productivity and extending equipment life.

Conclusion

When it comes to industrial automation, choosing the right China VFD (Variable Frequency Drive) is a pretty big deal if you want things to run smoothly and efficiently. It’s really important to get a good handle on what VFDs are all about because they’re key players in controlling motor speed and torque in a bunch of different applications. There are a few main types of China VFDs out there, each one tailored for specific needs — so factors like compatibility, scalability, and features should definitely be on your mind when you’re making a pick.

At Zhejiang Chuanken Electric Co., Ltd., we’ve been around for 15 years, focusing on industrial automation control products, and we’re here to help you navigate through the options. We’ll break down some of the top China VFD brands, highlighting what they do well and how they perform. Plus, we want to clear up some common misconceptions about how reliable these China-made VFDs really are, so you can make smarter, more confident decisions for your setup. Follow a few best practices when rolling out VFDs, and you’ll see your operation run more smoothly — helping your business grow and succeed.

Overall, it’s all about finding the right fit and knowing what to look for. Don’t worry — we’ve got your back every step of the way!

Related Posts

-

Step-by-Step Guide to Sourcing the Best China VFD for Your Business Needs

-

How to Choose the Best China VFD for Your Industrial Needs: A Comprehensive Guide

-

Understanding the Best Chuanken Soft Starter Technology and Its Applications

-

How to Navigate the 2025 Trends in Vfd Power Cable Selection for Global Buyers

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Elevating Global Standards with Best 250 Kw Vfd Drive From China