How to Select the Right VFD for Your 11kW Motor Applications

Table of Contents

- Understanding the Basics of VFD and Its Importance for 11kW Motors

- Key Specifications to Consider When Selecting a VFD

- Evaluating Compatibility Between VFDs and 11kW Motors

- Assessing Your Application Needs for Optimal VFD Performance

- Exploring Common VFD Features and Their Benefits

- Cost-Effectiveness: Balancing Investment and Energy Savings with VFDs

- Optimizing Motor Performance: The Benefits of the General VFD 55kw 380V 3Phase Inverter Frequency Converter

- FAQS

- Conclusion

- Related Posts

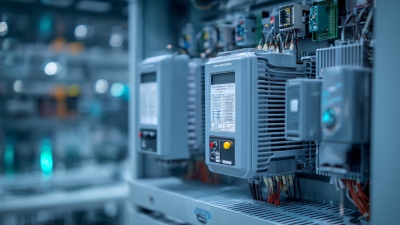

When it comes to industrial automation, picking the right

Variable Frequency Drive (or VFD) for an 11kW motor isn’t just a technical decision — it’s kinda crucial if you want things to run smoothly and save energy at the same time.

I came across a report from MarketsandMarkets that said the global VFD market is set to hit around $24 billion by 2026, mainly because more industries are looking for smarter, energy-efficient options.

As someone who's been in this game for over 15 years, Zhejiang Chuanken Electric Co., Ltd. really knows their stuff when it comes to advanced automation control products.

We’re here to make sure our customers get the best VFD solutions tailored to their needs.

Trust me, understanding the key points—like making sure the VFD works well with your motor, handles your load, and fits your control style—is so important if you want your 11kW setup to be reliable and efficient.

When it comes to industrial automation, picking the right

Variable Frequency Drive (or VFD) for an 11kW motor isn’t just a technical decision — it’s kinda crucial if you want things to run smoothly and save energy at the same time.

I came across a report from MarketsandMarkets that said the global VFD market is set to hit around $24 billion by 2026, mainly because more industries are looking for smarter, energy-efficient options.

As someone who's been in this game for over 15 years, Zhejiang Chuanken Electric Co., Ltd. really knows their stuff when it comes to advanced automation control products.

We’re here to make sure our customers get the best VFD solutions tailored to their needs.

Trust me, understanding the key points—like making sure the VFD works well with your motor, handles your load, and fits your control style—is so important if you want your 11kW setup to be reliable and efficient.

Understanding the Basics of VFD and Its Importance for 11kW Motors

Variable Frequency Drives, or VFDs for short, are pretty essential when you're trying to get the best out of 11kW motors. Honestly, understanding the basics—like how they control the motor’s speed and torque—can make a big difference, especially since different motors like AC induction, DC, and brushless DC each have their own quirks. For example, AC induction motors usually need VFDs that can handle higher currents, while brushless DC motors often require more precise control schemes, especially in applications where accuracy really counts.

Talking about power ratings, VFDs come in all shapes and sizes. If you’re working with motors up to around 25kW, you'll find the VFDs tend to be simpler and more budget-friendly. But when you move into the 25kW to 100kW range, those VFDs usually pack more features to handle heavier loads and more demanding performance needs. Whether you're into industrial stuff, consumer electronics, or medical equipment, picking the right VFD is super important for keeping things running smoothly and efficiently. It’s pretty interesting to note that the market for adjustable speed drives was worth about $650 million in 2022, and experts think it'll hit around $910 million by 2030—that just shows how much these little gadgets are growing in popularity across all kinds of sectors.

Key Specifications to Consider When Selecting a VFD

When you're choosing a Variable Frequency Drive (VFD) for an 11kW motor, there are a few key specs you definitely wanna keep in mind. These details really matter because they affect not just how well the motor runs, but also how much energy you're gonna save. For starters, make sure the VFD's voltage and current ratings match your motor's requirements—they gotta be compatible, or risk overheating or other issues. Also, it’s worth thinking about the control methods, like V/Hz, vector control, or PWM (Pulse Width Modulation). Picking the right one can really help the system perform better under different loads.

Oh, and don’t forget to check the manufacturer’s guidelines on power losses—using a good quality VFD can boost your system efficiency by up to 30%. Plus, you’ll want to think about where the VFD will be working. If it’s in a harsh environment, look for units with higher ingress protection (IP) ratings—that way, you’re sure it can handle the conditions and last longer.

Another thing to consider is the VFD’s braking ability—especially if your setup involves lots of starts and stops. Good braking capability can actually help prevent damage to both the motor and the drive. And here’s a neat bit of info: using VFDs can really cut down energy costs, especially in things like screw air compressors, where they can reduce power usage quite a bit. All in all, investing in the right VFD isn’t just about compatibility—it’s about boosting efficiency and saving money in the long run.

Evaluating Compatibility Between VFDs and 11kW Motors

When you're picking out a Variable Frequency Drive (VFD) for an 11kW motor, making sure they're compatible is a must. One of the key things to check is the voltage rating — most 11kW motors usually run around 400V or 480V. There's actually a report from the International Electrotechnical Commission (IEC) that warns if the voltages don’t match up properly, it can cause some serious inefficiencies or even risk damaging either the motor or the VFD. So, honestly, matching the VFD to your motor’s voltage is really important if you want things to run smoothly and last longer.

Another thing to keep in mind is what kind of motor you’re working with—whether it’s induction, synchronous, or a servo motor. Each type comes with its own set of quirks and benefits, especially when pairing with the right VFD. For example, some research from the Electric Power Research Institute (EPRI) shows that using a VFD tailored to the motor’s control needs can cut down energy use by up to a quarter. Plus, you gotta make sure the VFD’s output frequency range covers what the motor needs so it doesn’t stall, overheat, or wear out prematurely. Doing that not only keeps things running smoothly but also extends the lifespan of your equipment and boosts efficiency.

Assessing Your Application Needs for Optimal VFD Performance

When you're choosing a Variable Frequency Drive (VFD) for your 11kW motor setup, it’s really important to get a good handle on what your specific application needs. Different types of equipment have their own unique demands on the motor and VFD. For example, a pump might need a super smooth start and steady speed control, whereas a conveyor system might require quick acceleration and frequent speed adjustments. Figuring out these details ahead of time will help you pick a VFD that’s up to the task and performs reliably.

A couple of tips: think about the torque you’ll need. If your setup calls for a high starting torque, go for a VFD that's built to handle that. Also, don’t forget to consider the environment—things like temperature and humidity matter because they can influence how well your VFD works and how long it lasts.

It’s also smart to think ahead—if you might want to upgrade or expand your system in the future, choosing a VFD with those options in mind can save you hassle down the road. Compatibility with communication protocols can also be a big deal if your system is part of a larger automation setup. Taking the time to evaluate all these factors means you’ll end up with a VFD that not only fits your current needs but is flexible enough to grow with you and adapt to new tech that's coming down the line.

Exploring Common VFD Features and Their Benefits

So, when you're picking out a Variable Frequency Drive (or VFD) for an 11kW motor, it's pretty important to get a good handle on the key features and what they can do for you. Modern VFDs, for example, are pretty great at saving energy — and that’s no small thing. The U.S. Department of Energy has said that in applications like fans and pumps, VFDs can cut down energy use by anywhere from 20 to 50%. That means not only saving some cash on your power bills, but also giving a little boost to your sustainability efforts in the process.

Another thing to watch for is how advanced the motor control features are. Things like sensorless vector control and direct torque control can make a real difference. They help your motor run more smoothly and respond a lot better. According to research from IEEE, using these controls can boost speed regulation accuracy by up to 20%. That’s a big deal for stuff that needs precision, like conveyor belts or CNC machines. Plus, many VFDs come with built-in safety features — like protections against overloads or overheating — which help keep both the VFD and the motor safe and last longer. All in all, choosing a VFD with these features can really make a difference in how well your equipment performs and how long it lasts.

Cost-Effectiveness: Balancing Investment and Energy Savings with VFDs

When you're shopping around for the right Variable Frequency Drive (VFD) for an 11kW motor, one thing that's usually at the top of the list is cost — but it's not just about the sticker price. Investing in a VFD can seem pricey upfront, but it pays off over time through energy savings and more efficient operation. In today’s push for greener, more sustainable manufacturing, using VFDs really makes a difference — they help cut emissions and lower your ongoing costs. Interestingly, the market for VFDs in North America is booming; it’s expected to hit around USD 5.3 billion by 2024, growing at roughly 6.2% annually. That growth really shows how everyone’s starting to see VFDs as a key way to save energy.

A good tip is to look at how much energy you could save over time and figure out how long it’ll take to recoup your investment. There's actually tools out there that make these calculations pretty straightforward — giving you a clear picture of how soon you'll start seeing the benefits in your wallet. Plus, upgrading to a VFD isn’t just about making your motors run smoother; it’s also a step toward more eco-friendly manufacturing by using energy smarter.

And when you're choosing a VFD, make sure it matches your motor's specific needs. Some fancy models, like smart VFDs, can adjust on the fly based on load changes, which is especially useful in industries like oil and gas where efficiency really matters. Picking the right one means you’re not just saving energy—you’re making your operation more sustainable overall. It’s about balancing the costs with those long-term savings, right?

Optimizing Motor Performance: The Benefits of the General VFD 55kw 380V 3Phase Inverter Frequency Converter

The General VFD 55kw 380V 3Phase Inverter Frequency Converter, specifically the SHCKELE model SCK300, presents a remarkable solution for optimizing motor performance. Designed for general use, this inverter offers exceptional efficiency and precision, ensuring that motors operate smoothly across a variety of applications. With its ability to control motor speed and torque, the SCK300 significantly enhances productivity while reducing energy consumption, making it an ideal choice for industries looking to improve their operational efficiency.

One of the key advantages of the SHCKELE SCK300 is its robust warranty of 18 months, providing users with peace of mind and assurance in their investment. This durability, combined with cutting-edge technology, makes it a reliable choice for both commercial and industrial settings. By integrating the SCK300 frequency converter into your systems, you can experience not only enhanced motor performance but also the long-term savings that come from reduced energy costs and improved machine lifespan.

FAQS

: When selecting a VFD, consider the voltage and current ratings, control methods (like V/Hz, vector control, or PWM), braking capability, and the operational environment (including ingress protection ratings).

The voltage and current rating must align with the motor's specifications to ensure compatibility and prevent overheating, which is essential for safe and efficient operation.

The control method (such as V/Hz, vector control, or PWM) optimizes performance under varying load conditions, impacting the efficiency and effectiveness of the motor operation.

VFDs can lead to significant energy savings, especially in applications like screw air compressors, where they drastically reduce power consumption, making them a cost-effective investment.

It's essential to consider torque characteristics, ambient conditions (temperature and humidity), and any potential future upgrades or integration with broader automation systems.

Assess anticipated energy savings and the amortization period for your investment, utilizing tools to calculate how quickly you'll recoup costs through energy savings while considering the enhancement of motor performance.

Effective braking capability is crucial for applications involving frequent starts and stops, as it prevents potential damage to both the motor and the drive.

Opting for a VFD that accommodates potential upgrades or expansions can save time and resources, ensuring it remains effective as operational needs evolve.

Smart VFDs can adapt to changing loads, making them suitable for various applications and contributing to energy efficiency, particularly in sectors like oil and gas.

Compatibility with communication protocols is important for applications that integrate with broader automation systems, aiding in seamless operational efficiency.

Conclusion

When you're choosing the right VFD for your 11kW motor setup, it’s really important to get a solid understanding of what variable frequency drives actually do—mainly how they boost your motor’s efficiency and overall performance. You’ll want to look into key specs like voltage, current capacity, and control options to make sure the VFD you pick lines up with your motor’s requirements. Plus, think about what your specific application needs are and explore the different features various VFDs offer—things like energy savings and more flexible operation can really make a difference.

With over 15 years of experience in industrial automation products, Zhejiang Chuanken Electric Co., Ltd. knows that finding the right VFD is all about balancing upfront costs with long-term benefits. Taking the time to consider these points can help you pick a VFD that not only performs well but also saves you money in the long run and keeps things running smoothly for your 11kW applications.

Related Posts

-

The Ultimate Checklist for Sourcing the Best Vfd Abb for Your Industrial Needs

-

How to Choose the Best 45kW VFD for Your Industrial Applications

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements

-

Maximizing Efficiency: Essential Tactics for 1 Hp Vfd Applications in Modern Industry

-

Mastering Vfd 3 Phase Output 22kw 30hp Setup for Optimal Performance

-

Innovative Vfd 200kw Solutions for Global Buyers A Comprehensive Comparison