Exploring the Versatility of the Best 160kw Soft Starter: Applications and Key Features

Table of Contents

- Types of Soft Starters: Understanding the 160kw Variants

- Key Features to Look for in a 160kw Soft Starter

- Common Applications of 160kw Soft Starters in Industry

- Benefits of Using a 160kw Soft Starter for Motor Control

- Comparing 160kw Soft Starters: Leading Brands and Models

- Installation and Maintenance Tips for 160kw Soft Starters

- FAQS

- Related Posts

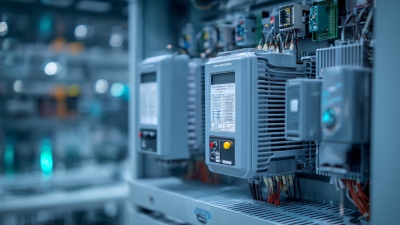

When you think about industrial automation these days, you can't ignore just how vital good motor control systems have become. With the world pushing harder for energy-efficient solutions and really reliable performance, having the right equipment makes all the difference.

Take the top-notch 160kW Soft Starter, for example — it’s a total game-changer across so many different setups. It lets motors start smoothly, which not only keeps things running quietly but also cuts down on electrical hiccups and mechanical wear and tear. I’ve read that the global market for soft starters is expected to hit around $2.5 billion by 2026, growing steadily at about 5.4% each year.

What's driving all this growth? Thanks to constant tech advancements and the push towards more sustainable, eco-friendly options. Zhejiang Chuanken Electric Co., Ltd., for instance, has been in the game for over 15 years. They're really leading the charge in this space — focusing on R&D and making high-tech automation control products that boost efficiency and reliability across industries. Pretty exciting stuff, right?

Take the top-notch 160kW Soft Starter, for example — it’s a total game-changer across so many different setups. It lets motors start smoothly, which not only keeps things running quietly but also cuts down on electrical hiccups and mechanical wear and tear. I’ve read that the global market for soft starters is expected to hit around $2.5 billion by 2026, growing steadily at about 5.4% each year.

What's driving all this growth? Thanks to constant tech advancements and the push towards more sustainable, eco-friendly options. Zhejiang Chuanken Electric Co., Ltd., for instance, has been in the game for over 15 years. They're really leading the charge in this space — focusing on R&D and making high-tech automation control products that boost efficiency and reliability across industries. Pretty exciting stuff, right?

Types of Soft Starters: Understanding the 160kw Variants

Soft starters have really become a key part of industrial setups these days, especially for motors in the 100 kW to 160 kW range. If you're dealing with or considering the 160 kW models, it's pretty important to get a good grasp on the different types out there—because knowing your options is crucial for making sure everything runs smoothly. Basically, soft starters fall into two main categories: voltage ramp starters and current limiting starters. The voltage ramp ones work by gradually increasing the voltage to the motor, which cuts down on those big inrush currents—sometimes by as much as 50%. That’s a big help in extending the life of your equipment and easing mechanical stress on the connected parts.

Lately, industry reports have been buzzing about the global soft starter market, which is expected to hit around USD 6.48 billion by 2026. That’s growing at about 5.6% annually since 2021. A lot of this growth is driven by the push for better energy efficiency and the increasing adoption of automation across sectors like water treatment, HVAC, and manufacturing. Plus, newer digital soft starter tech offers more precise control and monitoring features. This makes it easier for operators to fine-tune their systems and keep things running at peak performance. All of this just highlights how important it is to choose the right soft starter for your specific needs—because the right choice can make a real difference in how smoothly your operations run.

Key Features to Look for in a 160kw Soft Starter

When you're in the market for a 160kW soft starter, it’s really important to get a good handle on its key features. Trust me, understanding what those features do can make a huge difference in ensuring your system runs smoothly and reliably. These soft starters are pretty clever—they’re mainly designed to manage the initial surge of current when starting your motors, which helps cut down on mechanical stress and, over time, keeps your motor healthier and lasts longer. Some features you definitely want to look out for include adjustable starting torque, a three-phase phase control algorithm, and built-in protections like overheating, overcurrent, and phase loss alarms.

When you're evaluating different models, a couple of things are worth considering. First, make sure it works well with your existing motor and automation setup—nothing more frustrating than buying something that doesn’t quite fit. It's also worth choosing a model with an easy-to-use interface and programmable options; this saves you a lot of setup headaches and reduces the chance of mistakes. Plus, if energy-saving features are baked in, that can seriously cut down your operational costs—especially if you’re running things on a large scale.

And don’t forget about support. It’s super helpful to buy from a reputable manufacturer that offers solid customer service and knowledgeable technicians who can help with installation or troubleshooting. This way, you’re not only making sure you get the most out of your soft starter, but you also keep things running smoothly, even in tough or demanding situations.

Exploring the Versatility of the Best 160kw Soft Starter: Applications and Key Features

| Feature | Description | Applications |

|---|---|---|

| Voltage Rating | Typically rated for 380-480V | Industrial motors, pumps, fans |

| Control Method | Voltage ramp-up and ramp-down control | Start/stop operations in manufacturing |

| Overload Protection | Protects against motor overheating | Pumping, HVAC systems |

| Soft Start Capability | Gradual increase of voltage to reduce stress | Cranes, conveyors, and elevators |

| Compact Design | Space-saving with efficient heat dissipation | Flexible installation in control panels |

| User Interface | LCD display for easy monitoring | User-friendly operation in various settings |

| Temperature Rating | Operating temperatures up to 60°C | Harsh environments in industrial settings |

| Safety Certifications | Compliance with international safety standards | Reliability in different countries and regulations |

Common Applications of 160kw Soft Starters in Industry

The 160kW soft starter is pretty much essential in a bunch of industrial setups, and for good reason. It offers some pretty big perks when it comes to efficiency and keeping your equipment running longer. You’ll often see it used with big motors — think pumps, compressors, and fans. The cool thing is, it gradually ramps up the voltage, which helps cut down on those sudden inrush currents. That means less mechanical stress on your gear, and it helps the motors and everything connected last longer. Plus, starting up smoothly not only makes things safer but also boosts overall system performance.

Another area where these soft starters really shine is in conveyor systems. You know how a jolt or sudden start can mess up a flow of materials? Yeah, that’s a pain. But with a 160kW soft starter, the conveyor accelerates smoothly, keeping production running seamlessly. This is especially crucial in industries like manufacturing and distribution, where a consistent workflow isn’t just nice — it’s a must. And the fact that you can tweak settings, like the starting torque and acceleration time, means operators can really customize things to fit their needs. All in all, this means less wear and tear on your machinery and a more reliable setup all around.

Benefits of Using a 160kw Soft Starter for Motor Control

When it comes to controlling motors, using a 160kW soft starter really has some pretty big perks that can boost performance and efficiency across different setups. Basically, it lets the motor start up more smoothly by gradually increasing the voltage, which helps cut down on those huge inrush currents and reduces the mechanical strain on everything. That slow, controlled ramp-up also means there's less chance of damaging the motor or other connected parts, so it tends to last longer and stay healthier over time.

Plus, these soft starters are often packed with handy features that make the whole system more reliable and safe. For example, built-in protections like overload detection and thermal sensors kick in to prevent small issues from turning into big problems. Not only does that protect your equipment, but it also helps keep maintenance costs down in the long run. The best part? You can tweak the settings to match your specific needs, which makes these soft starters super versatile — pretty much a must-have for modern industrial motor control.

Comparing 160kw Soft Starters: Leading Brands and Models

When you're trying to pick out the right 160kW soft starter for your project, it really helps to get a good handle on the top brands and models out there. You’ve probably heard of some big players like Siemens, Allen-Bradley, and Schneider Electric — they all dish out solid options, each with their own unique features. For example, Siemens’ SIRIUS 3RW series is pretty versatile and works well in all sorts of environments—whether you’re dealing with pumps or fans, it just gets the job done efficiently. I read somewhere that the global soft starter market is expected to hit around USD 2.1 billion by 2025, which shows just how much more people are leaning towards energy-efficient motor control these days. Crazy, right?

Anyway, when you’re comparing models, it’s not just about the price. You wanna look at stuff like start-up current limits, control options, and thermal protection. Allen-Bradley’s 150S series, for instance, offers some pretty high-end features and advanced programming—great if your application is a bit more complex. My advice? Think about what exactly your project needs, make sure the soft starter plays nicely with your existing gear, and don’t forget to check out the support and warranty from the manufacturer.

Oh, and one more thing—consider how energy-efficient these starters are. Some, like Schneider Electric’s Altistart series, not only give you a smooth start for your motors but can also help cut down on energy costs by reducing peak demand. Taking the time to really understand these features can make a big difference in choosing the right one, leading to better system performance and fewer headaches down the line.

Installation and Maintenance Tips for 160kw Soft Starters

When you're setting up a 160kW soft starter, it’s really important to follow some industry best practices. Trust me, it makes a big difference in how well everything runs and how long your equipment lasts. The IEC folks recommend making sure the size and mounting are just right—this helps cut down on electrical stress and reduces heat build-up. Also, try to keep at least 10 centimeters of space between the soft starter and any other parts; this way, airflow isn’t blocked, and cooling stays effective. Oh, and don’t forget to use the right kind of cables that meet NEC standards. Proper wiring helps prevent voltage drops, which can mess with the soft starter’s efficiency.

Exploring the Versatility of the Best 160kW Soft Starter

FAQS

: The main types of soft starters for 160kW motors are voltage ramp starters and current limiting starters. Voltage ramp starters gradually increase the voltage applied to the motor, reducing inrush currents by up to 50%.

Soft starters are important because they control inrush currents, reduce mechanical stress on equipment, prolong motor life, and enhance operational safety.

Key features to consider include adjustable starting torque, three-phase phase control algorithms, built-in protections against overheating and overcurrent, and ease of integration with existing systems.

Soft starters can lower operational costs through energy-saving features, thus enhancing overall efficiency, especially in large-scale operations.

Common applications include pumps, compressors, fans, and conveyor systems where controlled acceleration helps to minimize mechanical stress and improve system performance.

It’s essential to choose a reputable manufacturer that offers comprehensive customer support, skilled technicians for installation, and troubleshooting to ensure operational continuity.

By implementing a 160kW soft starter, conveyor systems can achieve smoother acceleration, which prevents disruptions in material flow and optimizes production efficiency.

The global soft starter market is expected to reach USD 6.48 billion by 2026, growing at a CAGR of 5.6% from 2021, driven by energy efficiency and increased automation.

Advancements in digital soft starter technology allow for more precise control and monitoring, enabling operators to achieve optimal performance in electrical systems.

These features allow operators to customize the soft starter to match specific motor requirements, reducing wear and tear, and enhancing equipment reliability.

Related Posts

-

Choose China’s Premier 250kw Soft Starters and Elevate Your Global Partnerships

-

10 Secrets to Finding the Best Chuanken Soft Starter for Your Business Needs

-

Ultimate Guide to Choosing the Best Chuanken Soft Starter for Your Needs

-

Leading VFD Pump Controller Manufacturers from China at the 137th Canton Fair

-

Unlocking Efficiency: A Comprehensive Tutorial on Selecting the Best 0.75kw VFD for Your Industrial Needs

-

Unlocking Future Potential with Best Vfd 5.5kw Solutions in 2025 Technology Advancements