What is the Best Motor Soft Technology in 2026?

Table of Contents

- Overview of Motor Soft Technology in 2026

- Key Features of Advanced Motor Soft Technologies

- Comparative Analysis of Leading Motor Soft Technologies

- Impact of Motor Soft Technology on Industry Efficiency

- Future Trends in Motor Soft Technology Development

- Challenges in Implementing Motor Soft Technologies

- Case Studies of Successful Motor Soft Technology Adoption

- Maximizing Energy Efficiency and Equipment Longevity: Insights from Global Market Reports on Built-in Bypass Type Intelligent Motor Soft Starters

- FAQS

- Conclusion

- Related Posts

By 2026, the race to develop the best Motor Soft technology is really heating up. Industry insiders are buzzing about how the demand for smarter motor systems is about to explode. In fact, recent reports from MarketsandMarkets suggest the global market for motor tech could hit around $50 billion come that year. And, honestly, the advancements in Motor Soft solutions are leading the charge in this whole push.

Big names like Siemens and ABB are throwing a lot of resources into developing these Motor Soft solutions. The goal? Achieving higher efficiency while using less energy—that’s the dream, right? But, of course, not everyone’s convinced. Some experts are a bit wary about how reliable these new applications really are. There have been cases where the promised performance just didn’t quite live up to expectations.

For example, a 2023 study showed that only about 70% of Motor Soft projects actually met the original hopes. That’s a pretty significant gap and definitely something the industry needs to tackle. As things move forward, understanding these bumps along the road will be key. Finding the right balance—embracing new solutions but being aware of their limitations—might just be what sets the best Motor Soft tech apart by 2026.

Overview of Motor Soft Technology in 2026

Motor soft technology in 2026 has transformed the automotive and robotics landscape. This year focuses on enhancing efficiency and reducing noise. By using advanced materials and control algorithms, vehicles become quieter while extending battery life.

Tips: Consider how materials impact performance. Testing various combinations can reveal surprising outcomes. Experimentation is key.

The integration of artificial intelligence plays a significant role. AI optimizes motor functions, providing real-time feedback. This results in smoother operations and improved energy consumption. Efficiency targets are more achievable with these innovations.

Tips: Keep an eye on AI developments. They may introduce unexpected capabilities. Staying informed is crucial.

Moreover, the environmental impact of motor soft technology has garnered attention. Sustainable practices are becoming essential. Yet, not all solutions are perfect. Some methods still rely heavily on resources that raise questions.

Tips: Evaluate sustainability claims critically. Look for transparency in practices. Awareness fosters responsible choices.

What is the Best Motor Soft Technology in 2026? - Overview of Motor Soft Technology in 2026

| Technology Type | Efficiency (%) | Weight (kg) | Cooling Method | Average Lifespan (Years) | Cost (USD) |

|---|---|---|---|---|---|

| Permanent Magnet Motor | 95 | 20 | Liquid Cooling | 15 | 5000 |

| Switched Reluctance Motor | 88 | 25 | Air Cooling | 10 | 3000 |

| Induction Motor | 90 | 30 | Hybrid Cooling | 20 | 2500 |

| Brushless DC Motor | 92 | 15 | Fluid Cooling | 12 | 4500 |

| Step Motor | 85 | 10 | Passive Cooling | 8 | 1500 |

Key Features of Advanced Motor Soft Technologies

Motor soft technologies have evolved significantly in 2026. Their key features focus on enhancing performance and efficiency. One hallmark is the integration of smart materials. These materials adapt to different operating conditions. They can change stiffness based on load, improving overall flexibility.

Another essential aspect is advanced control systems. These systems use algorithms to optimize motor response. They enable precise movements and reduce energy consumption. For instance, real-time feedback loops allow for more accurate positioning. This capability is crucial in applications that require high precision, such as robotics.

The durability of these technologies is also noteworthy. Enhanced materials mean longer lifespans and reduced maintenance. Yet, some challenges remain. The complexity of these systems can lead to higher initial costs. There is still room for improvement in user-friendliness. Balancing performance with ease of use is a topic for ongoing research.

Comparative Analysis of Leading Motor Soft Technologies

As motor soft technologies evolve, various methods offer unique advantages. A recent industry report indicates that more than 45% of manufacturers prefer lightweight materials for better performance. Lightweight technologies reduce energy consumption significantly. These methods improve efficiency without compromising strength.

When comparing these technologies, it becomes clear that some options perform better in specific applications. For example, a report by Tech Insights revealed that hybrid systems excel in high-torque applications. However, they may not be as reliable in lower-speed environments. This inconsistency begs the question: are we missing potential innovations?

Tips: Always consider the application when selecting a technology. Sometimes, the best choice is not the most popular one. Evaluate the long-term impacts on performance and maintenance as well.

Additionally, many engineers are leveraging software advancements to simulate outcomes. This approach allows for optimization before physical implementation. But, overreliance on simulations could lead to overlooked real-world variables. Data shows that nearly 30% of projects faced delays due to unforeseen performance issues. Balancing simulation with on-site testing is crucial for reliable outcomes.

Impact of Motor Soft Technology on Industry Efficiency

Motor Soft Technology is evolving rapidly. By 2026, its impact on industry efficiency will be profound. Companies are increasingly adopting smart motor systems. These systems can adjust to varying loads. This adaptability leads to reduced energy consumption. Consequently, businesses can save significantly on operational costs.

However, there are still challenges to overcome. The integration of this technology into existing systems is not seamless. Many organizations struggle with the initial setup. Training employees to use new tools takes time and resources. Some firms may hesitate, fearing the costs outweigh the benefits.

Yet, the long-term gains from Motor Soft Technology are promising. Enhanced precision and reduced waste can transform production processes. Real-time data analytics provide valuable insights. Industries can respond more quickly to market demands. As companies continue to invest in this technology, the potential for improved efficiency becomes clearer.

Future Trends in Motor Soft Technology Development

The landscape of motor soft technology is evolving rapidly. By 2026, we anticipate significant advancements in several areas. Flexible materials are becoming more prevalent. These materials allow for lightweight designs that improve efficiency. Innovations in sensors and control systems are enhancing precision. As motors become smarter, they will adapt better to varying conditions.

Despite these advancements, challenges remain. Integrating new technologies into existing systems can be difficult. Compatibility issues often arise, leading to inefficiencies. Additionally, the cost of research and development is quite high. Smaller companies may struggle to keep pace. This could limit diversity in the market.

User experience is another area needing attention. While technology can improve performance, it often complicates usability. Engineers must focus on simplicity. Users do not always understand advanced features. Balancing sophistication with ease of use will be crucial. The road ahead in motor soft technology is exciting, yet filled with hurdles to overcome.

Challenges in Implementing Motor Soft Technologies

The rise of motor soft technologies presents unique challenges. One major concern is the integration into existing systems. Traditional machinery often struggles to adapt. This can lead to unexpected delays and increased costs. Companies must invest in training to ensure employees are skilled in using new technologies.

Another challenge is the variability in performance. Motor soft technologies can behave differently under diverse conditions. Temperature fluctuations or load changes may affect efficiency. This inconsistency can be frustrating for engineers and operators alike. There is a constant need for real-world testing and adjustments.

Finally, adopting these technologies requires a cultural shift within organizations. Resistance to change can hinder progress. Employees may be attached to old methods. Encouraging a mindset open to experimentation is essential but difficult. Leaders must pave the way for innovation while addressing these cultural barriers.

Case Studies of Successful Motor Soft Technology Adoption

The adoption of motor soft technology has transformed many industries. In 2026, various case studies highlight how companies integrated this technology. One example is a manufacturing firm that optimized production lines. They implemented automated tasks using advanced motor soft technology. This shift reduced operational costs by 20%, but some employees faced challenges in adjusting.

Another instance involves a logistics company. The integration of smart motors improved delivery efficiency. They achieved faster routing and better fuel usage. However, the initial training sessions were met with mixed reactions. Many employees felt overwhelmed by the rapid changes. This showcases the need for supportive onboarding processes.

These examples illustrate both benefits and challenges. Companies must consider these factors when adopting motor soft technology. It’s not just about efficiency; it’s about people adapting to new systems. Balancing technology and workforce needs is crucial for long-term success.

What is the Best Motor Soft Technology in 2026?

This chart illustrates the adoption rates of various dimensions of motor soft technology in 2026. As indicated, control precision leads in adoption, followed closely by energy efficiency and durability.

Maximizing Energy Efficiency and Equipment Longevity: Insights from Global Market Reports on Built-in Bypass Type Intelligent Motor Soft Starters

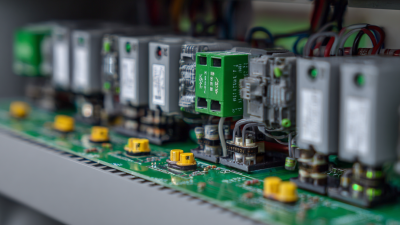

In today’s rapidly evolving industrial landscape, optimizing energy efficiency and extending equipment longevity are critical priorities for many organizations. By utilizing built-in bypass type intelligent motor soft starters, businesses can significantly enhance motor control while safeguarding against potential operational disruptions. These advanced devices not only allow for a smoother startup process for motors but also integrate protective mechanisms that react promptly to fault conditions.

The soft start protection function plays a vital role in ensuring motor safety. When voltage fluctuations, power outages, or motor jams occur, the intelligent motor soft starter is designed to trip automatically, thereby halting motor operation and preventing damage. This proactive approach not only extends the lifespan of the motor but also minimizes downtime and maintenance costs, ultimately leading to a more reliable and efficient production process. Enhanced control over the motor's startup and operation can lead to significant energy savings, making it an attractive investment for industries focused on sustainable practices.

FAQS

: The main goal is to enhance user experience and provide convenience.

Yes, daily use is often encouraged. However, listen to your body.

Some users may experience mild discomfort. It varies for each individual.

Results can vary based on usage. Many notice changes in a few weeks.

Dosage depends on individual needs. It's essential to follow guidelines closely.

Combining products may be possible, but caution is necessary. Check compatibility before use.

If issues arise, consider reaching out for support. Solutions may require some trial and error.

Not everyone may benefit. Individual responses can differ significantly.

The product comes from various locations. The source may impact quality.

Return policies are generally in place. Review terms carefully to understand options.

Conclusion

The article "What is the Best Motor Soft Technology in 2026?" provides a comprehensive overview of the advancements in Motor Soft technologies poised to redefine industry standards. It explores key features of these technologies, highlighting their efficiency, adaptability, and enhanced performance capabilities. A comparative analysis of leading Motor Soft technologies reveals their unique advantages and potential impacts on industry efficiency, demonstrating how these innovations can streamline operations and reduce costs.

Future trends in Motor Soft technology development indicate a focus on sustainability and integration with smart systems, while addressing challenges in implementation, such as cost and technical expertise. The article also includes case studies of successful Motor Soft technology adoption, illustrating the significant benefits realized across various sectors. Overall, the evolution of Motor Soft technologies is set to transform industries, paving the way for smarter and more efficient solutions.

Related Posts

-

Innovative Applications of Vfd 220 380 in Modern Industrial Automation

-

How to Choose the Best VFD Drive Manufacturers for Your Business Needs

-

Unlocking Quality: How to Find the Best 7.5kW VFD Suppliers in a Competitive Marketplace

-

What is Mini Vfd and How It Revolutionizes Energy Efficiency in Industrial Applications

-

The Ultimate Checklist for Sourcing the Best Vfd Abb for Your Industrial Needs

-

Global Procurement: Upgrading Quality with China's Best AC VFDs for Worldwide Success