Mastering the Installation of 250kw Soft Starters A Step by Step Guide for Global Buyers

Table of Contents

- Understanding 250kW Soft Starters and Their Applications in Industry

- Selecting the Right Soft Starter: Key Considerations for Global Buyers

- Step-by-Step Installation Guide for 250kW Soft Starters

- Troubleshooting Common Installation Issues with Soft Starters

- Best Practices for Maintaining and Operating Soft Starters

- Exploring Future Trends in Soft Starter Technology and Global Market Insights

- Enhancing Motor Control Efficiency: A Deep Dive into the SCKR1-6200 Intelligent Soft Starter

- FAQS

- Conclusion

- Related Posts

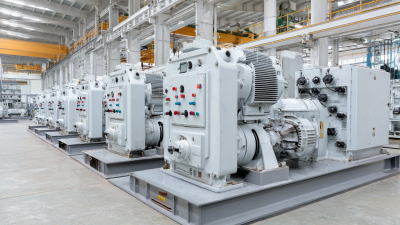

In the fast-changing world of industrial automation, the installation and smooth operation of 250kW Soft Starters have really become key factors for buyers worldwide who are looking to optimize their systems. According to the International Electrotechnical Commission, the global market for soft starters is expected to grow quite a bit — mainly because more and more companies are seeking energy-efficient motor control solutions. At Zhejiang Chuanken Electric Co., Ltd., we’ve been at this for over 15 years, focusing on R&D, manufacturing, and selling automation control products. We’re proud to be leading this charge. Our dedication to quality and innovation means we can offer some really advanced soft starters that not only boost how electrical systems perform but also promise reliability and safety in tough industrial environments. This little guide is here to help buyers all over the world understand how to install 250kW Soft Starters properly — with the goal of giving your business the tools to stay competitive and grow.

Understanding 250kW Soft Starters and Their Applications in Industry

Understanding 250kW Soft Starters and How They Fit Into Industry Today

Soft starters are honestly a game-changer for a lot of heavy-duty industrial setups, especially when it comes to managing big electric motors. A 250kW soft starter is really good at starting and stopping motors smoothly — it helps cut down on that banging mechanical stress and keeps your equipment running longer. I recently read in a MarketsandMarkets report that the global market for soft starters is expected to jump from around USD 1.2 billion in 2020 to about USD 1.9 billion by 2025, which is a solid 10.3% growth rate. That’s a pretty clear sign that more industries—think manufacturing, HVAC, water treatment—are catching on and using these devices more and more.

One of the biggest perks of using a 250kW soft starter is how well it can control the initial rush of current—a.k.a. the inrush current—that happens when a motor kicks in. For example, when you start a big motor, it can draw up to six times the current it normally uses, which can cause all sorts of electrical and mechanical shocks. Soft starters limit that surge—often cutting it by more than half—so you’re not risking damage to your motors or other equipment. Plus, they’re pretty versatile, working with everything from conveyor belts to pumps, making them a must-have to keep industrial operations smooth, efficient, and reliable these days.

Mastering the Installation of 250kw Soft Starters

| Parameter | Value | Application |

|---|---|---|

| Voltage Rating | 400V | Industrial Motors |

| Current Rating | 500A | Pumps and Fans |

| Control Type | Microprocessor | Conveyor Systems |

| Starting Method | Soft Start | Industrial Equipment |

| Protection Features | Overload, Under-voltage | Generators |

| Environment Rating | IP54 | Outdoor Installations |

| Weight | 35kg | Machine Integration |

| Dimensions (L x W x H) | 600 x 400 x 300 mm | Control Panels |

Selecting the Right Soft Starter: Key Considerations for Global Buyers

When you're choosing a soft starter, it's really important to start by figuring out what your specific application needs. Different industries, or even different machines within the same industry, might require different levels of torque control, starting current limits, or specific operating conditions. For instance, if you're working with a fan, you might need to handle a pretty high inrush current, but with a pump, a soft starter that allows a more gradual ramp-up could be the better choice. Basically, knowing exactly what your equipment needs helps you pick the right soft starter — one that’s gonna give you top performance and save energy at the same time.

Another key thing to keep in mind is whether the soft starter is compatible with your existing electrical setup. You’ll want to check the voltage and current ratings of both the soft starter and the motor it’ll be connected to. Plus, the control features matter too — stuff like built-in protections, communication options, and programmability. Making sure these line up with your control system can make installation a lot smoother and boost overall reliability. In the end, understanding these specs can lead to safer operation and fewer unexpected downtimes.

Soft Starter Selection Considerations

This bar chart illustrates the key considerations for selecting a soft starter, rated on a scale of 0-10 based on their importance when making a purchase decision. Voltage and current ratings are the most critical factors, followed by starting torque and protection features.

Step-by-Step Installation Guide for 250kW Soft Starters

When you're installing a 250kW soft starter, following a step-by-step guide really helps things go smoothly and makes sure you're sticking to

industry standards. I came across a recent report that says the market for these soft starters is expected to grow quite a bit—that's good news, especially with

demand picking up in both homes and commercial setups. If you're shopping around, it’s pretty important to understand what the main parts are and how the installation works. That way, you can

optimize energy use and make your operations run more smoothly.

Installing these devices isn’t just about hooking up some wires; it’s more like taking a holistic approach to energy management—especially now, as we’re aiming for some

pretty ambitious energy storage goals by 2025. Industry data suggests that integrating soft starters with energy storage systems can boost energy efficiency by

up to 30%. Plus, soft starters are now really good at working with new tech like small

DC-DC converters, which helps manage energy flow more effectively. This makes them absolutely essential in today’s power systems. If you follow a careful

installation process, you’ll unlock the full potential of these important components and get the most out of your setup.

Troubleshooting Common Installation Issues with Soft Starters

When you’re installing a 250kW soft starter, it’s really important to keep an eye out for potential issues that might pop up along the way. As a company that's been in industrial automation for over 15 years—yeah, we’re talking about Zhejiang Chuanken Electric—we know that good planning and preparedness make all the difference. Before you dive into the installation, make sure all the parts are compatible and do a thorough check on your electrical setup. It’s better to catch any hiccups early than deal with surprises later on.

One common mistake folks make is wiring things incorrectly, which can cause the whole system to fail or run poorly. So, take your time double-checking every connection, and don’t forget to keep the wiring diagram handy—it’s your best friend here. Also, make sure your power supply matches what the soft starter needs; a mismatch can lead to all sorts of headaches.

Another thing to watch out for is overheating during operation. This usually happens if there isn’t enough cooling in place. Take a moment to evaluate your environment—if things seem a bit stuffy, consider adding some ventilation or cooling solutions. Regular maintenance and keeping an eye on the temperature can really help keep everything running smoothly and extend the lifespan of your equipment. Bottom line: tackling these issues early on not only boosts safety but also makes your whole operation run more efficiently and reliably.

Best Practices for Maintaining and Operating Soft Starters

When it comes to keeping your soft starters in good shape and running smoothly, following some best practices is really key. Doing regular maintenance can make a big difference in how well these devices perform and how long they last. I’ve seen industry reports that say if you’re not careful with how you handle soft starters, their efficiency can drop by around 30% over time. That’s no small thing—it means you'll end up using more energy and there’s a higher chance of something breaking down unexpectedly.

A smart approach is to set up a maintenance schedule that's not too complicated: just routine checks, cleaning, and testing to make sure everything’s working as it should. When cleaning, it’s best to use gentle, appropriate cleaners—biocidal ones are usually recommended to prevent nasty residue buildup. Plus, it’s a good idea to have your technicians go through training programs that cover the latest on installation and operation. Apparently, companies that make a point of training their staff on soft starter tech see up to a 40% boost in reliability and fewer shutdowns, which really shows how important ongoing learning is when it comes to keeping equipment in tip-top shape.

Exploring Future Trends in Soft Starter Technology and Global Market Insights

The soft starter technology market is really moving fast these days, and we're seeing some pretty exciting signs that people are really looking for energy-efficient solutions across a bunch of different industries. As companies and buyers around the world get more familiar with these new innovations, a few key things are driving the change — like breakthroughs in semiconductor tech and the push towards digital integration. Looks like the market for soft starters is about to grow a lot, especially with the whole focus on automation and saving energy.

And it’s not just about tech — there’s a bigger shift towards sustainability happening too. More companies are now on the lookout for eco-friendly options, and that’s pretty much aligned with new rules aimed at cutting down energy use and carbon emissions. That’s great news for soft starters because they not only help make electric motors more efficient, but they also support more responsible industrial practices. Looking ahead, buyers can expect a bunch of new products that aren’t just designed to get the job done but also fit with the bigger goal of being greener in the long run.

Enhancing Motor Control Efficiency: A Deep Dive into the SCKR1-6200 Intelligent Soft Starter

The SCKR1-6200 intelligent soft starter represents a significant leap in enhancing motor control efficiency. With its remarkable capability of offering six distinct starting modes, this advanced device allows for tailored performance suitable for a wide range of applications. Whether you need a gentle start to minimize mechanical stress or a quick ramp-up for peak performance, the SCKR1-6200 adapts to the specific needs of your motor, ensuring optimal operation and extending equipment life.

In addition to its versatile starting modes, the SCKR1-6200 excels in safety and reliability with twelve comprehensive protection functions. This feature ensures that motors are safeguarded against overload, phase loss, and other electrical anomalies, thus reducing downtime and maintenance costs. Furthermore, the two vehicle modes enhance the soft starter's functionality, making it an excellent choice for various vehicular applications and industrial environments. By integrating such intelligent solutions, the SCKR1-6200 not only boosts efficiency but also fosters a more sustainable operation by minimizing energy consumption and wear.

FAQS

: Common installation issues include improper wiring, which can cause operational failures, and overheating during operation due to inadequate cooling solutions.

To ensure proper wiring, double-check all connections and refer to the manufacturer's wiring diagram for guidance.

Ensure that the power supply meets the specifications required by the soft starter to avoid operational issues.

Overheating is often caused by inadequate cooling solutions. It can be mitigated by assessing the installation environment and incorporating ventilation or cooling systems as needed.

Regular maintenance is crucial as it can significantly enhance performance, prevent a 30% decrease in efficiency over time, and reduce energy consumption.

A maintenance schedule should include routine inspections, cleaning, and testing of the soft starters to ensure optimal functioning.

Technician training is important because companies that regularly train their staff on soft starter technologies see up to a 40% improvement in reliability and reduced downtime.

Trends include advancements in semiconductor technology, digital integration, and a growing focus on energy-efficient and sustainable solutions.

The global marketplace is anticipated to expand due to the shift towards eco-friendly solutions and regulatory policies aimed at reducing energy consumption and carbon footprints.

Buyers can expect a range of new products that meet operational needs while aligning with global sustainability goals in the coming years.

Conclusion

In today’s industrial world, getting a handle on installing a 250kW Soft Starter is pretty much essential if you want to keep things running smoothly and efficiently. This guide is here to walk you through everything—you’ll understand how these soft starters work, what they’re used for, and what key factors folks around the globe should keep in mind when choosing the right one. From a step-by-step breakdown of the installation process to troubleshooting those annoying little issues that pop up sometimes, this blog offers practical tips to help you get comfortable with the whole soft starter tech without feeling overwhelmed.

Zhejiang Chuanken Electric Co., Ltd. brings 15 years of know-how in industrial automation control products. They focus on best practices for keeping these devices in tip-top shape and operating smoothly. Plus, the article dives into what’s coming next in soft starter tech and shares some market insights—so, you’re not just getting the basics, but also staying ahead of the curve. Overall, this guide not only boosts your technical understanding but also helps you make smarter decisions, especially if you’re a global buyer looking to invest in a 250kW Soft Starter.

Related Posts

-

Essential Checklist for Choosing the Right 280kw Soft Starter for Your Business Needs

-

The Definitive Guide to Selecting the Perfect 280kw Soft Starter for Your Global Sourcing Needs

-

Choose China’s Premier 250kw Soft Starters and Elevate Your Global Partnerships

-

Understanding Industry Standards for Best Soft Starter Cabinet Selection Guide

-

Unveiling the Advantages of Soft Starters in 50Hz and 60Hz Applications for Enhanced Operational Efficiency

-

The Ultimate Guide to Understanding Vfd Drive Efficiency and Industry Applications